AI-designed Linux computer with 843 components boots on first attempt — dual-PCB Project Speedrun was made in just one week and required less than 40 hours of human work

Quilter, the LA-based startup behind this feat, says its dual-PCB Linux computer with 843 components was designed in just one week.

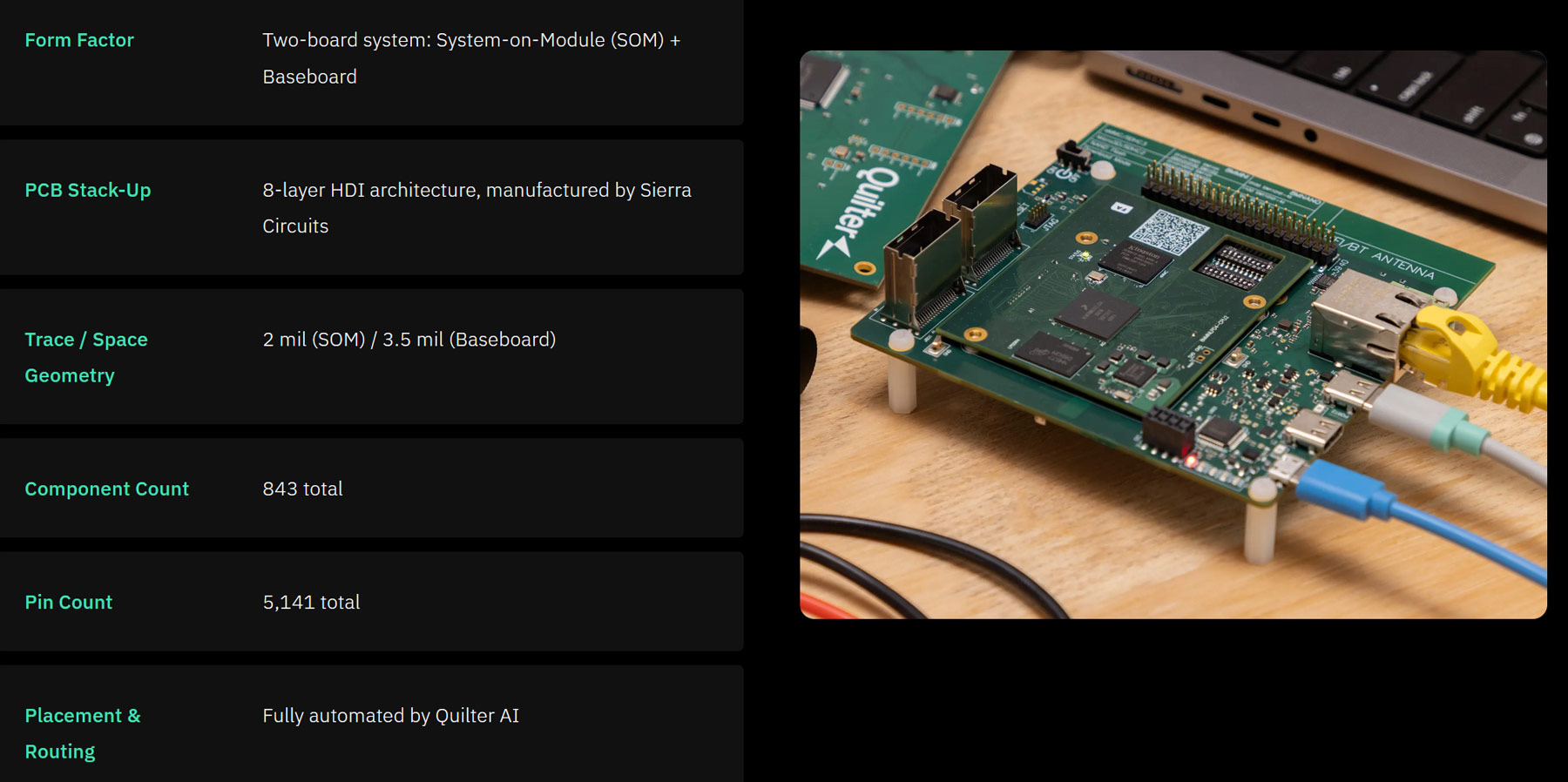

LA-based startup Quilter has outlined Project Speedrun, which marks a milestone in computer design by AI. The headlining claims are that Quilter’s AI facilitated the design of a new Linux SBC, using 843 parts and dual-PCBs, taking just one week to finish, then successfully booting Debian the first time it was powered up. The Quilter team reckon that the AI-enhanced process it demonstrated could unlock a new generation of computer hardware makers.

Tenfold time saver

The great attraction of AI-enhanced PCB design is that it offers the promise of removing a consistent bottleneck from computer system design. With just one week of AI-powered processing, augmented by 38.5 hours of human expert assistance, the Project Speedrun computer was completed. Normally, this kind of project would require approximately three months for a skilled human engineer (approximately 430 hours of work).

Quilter claims that prior expert human-based workflows would face a serious bottleneck to iterate a three-step process of setup, execution, and cleanup.

Before and after Quilter AI

Previously, humans would shepherd a design through all three of these key stages. However, with Quilter's AI on hand, they can instead focus on the creative setup and refinement at the cleanup stage, leaving the donkey work of the execution to AI. The Quilter team indicates its AI can handle all three stages, if you wish, though.

Streamlining the time-consuming execution stage using AI is very canny, for the reasons mentioned above – thus unlocking creativity, allowing engineers to try more designs, and/or get faster to market. Moreover, human execution of the design/setup can often have errors, meaning even more time needs to be focused on this middle step, holding up the entire project.

How this AI was trained

Venture Beat’s coverage contrasts Quilter AI against LLMs like GPT-5 and Claude. Indeed, circuit board design isn’t a language task or problem. Thus, the AI behind this tool is basically trained by playing an optimization game against the laws of physics.

Surprisingly, there were no earlier stages where Quilter AI was trained on human-designed sample boards. This decision was made because humans frequently make mistakes in board design, and to make sure Quilter AI’s capabilities weren’t somehow capped at human-level.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

With Project Speedrun's success, if it wasn’t a fluke, this philosophy seems to have paid off, with one engineer obviously surprised at the first-boot success, exclaiming, “Holy crap, it’s working.”

As we have hinted at above, the longer-term goal of Quilter's AI is to end up with a PCB design system that doesn’t just match humans but can “come up with better designs for circuit boards than humans have ever tried to do,” Sergiy Nesterenko, Quilter’s CEO and former SpaceX engineer, said.

Importantly, the abilities of Quilter are not only touted as time, iteration, effort, and human creativity savers. The startup heralds its project's potential to unlock a new generation of hardware startups, as it removes a significant barrier to entry.

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

Mark Tyson is a news editor at Tom's Hardware. He enjoys covering the full breadth of PC tech; from business and semiconductor design to products approaching the edge of reason.

-

bit_user I can see a downside to this. Currently, you can find lots of IoT and other smart devices using off-the-shelf industrial/embedded boards or even Arduinos and Raspberry Pi's of one flavor or another. The easier it is for them to make bespoke boards means they can pack more features or innovate on form factor, but if/when the device breaks, replacement parts will be entirely at the mercy of the device maker (who's hopefully still in business, by then). And if they don't happen to have any spares, it won't be economical for them to do a production run of only a couple more boards.Reply

The other downside of having more bespoke boards is that dumpster divers won't be able to crack open and harvest as many reusable boards from discarded equipment. I remember an article on here about an e-scooter embedding a full Raspberry Pi 4. This was a big deal, because the company had gone bankrupt and it was still in the era before Raspberry Pi 5, when the 4's were quite scarce. -

Conor Stewart This article and the company imply something that just cannot be true. That humans are capable of making mistakes but this AI isn't. So they are claiming an AI that is perfect at PCB design.Reply

Also another point that could be used to mislead people, this board was designed in a week using the AI and it worked the first time it was booted, but it doesn't say anything about previous attempts. Yes this run took a week and 40 hours of human work but that alone doesn't necessarily mean that it isn't attempt 1000 of trying to get this to work or that it wasn't down to random chance. Just because it booted doesn't mean all that much, it might not be stable, it might have very specific power or temperature requirements, it might be getting run at low clock speeds because it is unstable, etc.

Even if this is true they are making these impossible claims just to get funding. Claiming an AI makes no mistakes is just ridiculous at this point. It would be interesting to see a few experts not affiliated with the company review the PCB design.

It's also not clear if this was just PCB design or schematic design too. If the schematic was designed by humans then it is probably pretty likely that they could design the schematic/system to be as robust and reliable as possible so it is more tolerant of mistakes by the AI. -

Eximo Reply

Agreed, we've using 'AI' for board layout for decade(s) at this point. Can't recall the first time I encountered it in the wild. At least as far back as 2010, if not before, it was available as a software package and all you needed to accelerate it was an off the shelf consumer grade GPU. Prior to that I'm sure there were bespoke machines or less generalized software packages to do the same.umeng2002_2 said:Is this better than current design optimzation?

Given a fixed library of components, I don't think an AI could stray too far from anything outside what the application engineers whipped up in the first place. (Heck that is a lot of products, app engineer design simply built and implemented) -

endocine Would like to see this in the hands of the masses, so we all can design our own things, like motherboards, and have them manufactured at XXXway and other PCB outsources. Then another AI would write a customized EUFI. Then we can make our own boards with more PCIe slots, only 2 DIMM slots (or one if prices keep going up. lolz), and no RGB bawlucks.Reply -

umeng2002_2 Finite element and finite difference can design a usable bridge or wing in a day; but I wouldn't call it AI. Nor is it autonomous in the slightest. People need to be careful about using the term "AI." And frankly any closed loop iterative optimization can be called "machine learning." It's all marketing fluff.Reply -

bit_user Reply

Their point was that humans don't necessarily produce designs with the tightest timing, lowest losses, or best signal integrity and they didn't want AI to learn those sub-optimal practices.Conor Stewart said:This article and the company imply something that just cannot be true. That humans are capable of making mistakes but this AI isn't. So they are claiming an AI that is perfect at PCB design.

In either case, the design is checked with simulation software, in order to see if it meets the timing & other requirements, before it's sent off for fabrication. In the case of AI, you can use this simulation software in order to train it to make better designs. However, the way it learns is essentially by trial and error, rather than by trying to imitate designs that humans have made.

This was the first board they actually fabbed and tested out. It was their first attempt.Conor Stewart said:Also another point that could be used to mislead people, this board was designed in a week using the AI and it worked the first time it was booted, but it doesn't say anything about previous attempts.

Many times, a human-designed board doesn't boot on the first try. Then, you need to debug it, figure out why, and do some rework to correct the problem(s).Conor Stewart said:Just because it booted doesn't mean all that much,

Booting might sound fairly basic, but it involves a lot of functionality that all has to work right.

Yeah, the fact that they didn't say it worked flawlessly seems like a rather glaring omission. However, I didn't bother to track down the source to see if it's merely the article's omission. If not, then it's probably safe to assume it wasn't flawless.Conor Stewart said:it might not be stable,

Not when the problem domain is fairly constrained and the result has a definite correct answer. For all we know, there could be in-loop simulation that's used to help the AI iterate on the design. Then, by definition, it wouldn't produce anything that doesn't at least work in simulation.Conor Stewart said:Claiming an AI makes no mistakes is just ridiculous at this point. -

bit_user Reply

I'm sure the overheads of doing a production run of high-end PCBs would be impractically high for one-off boards. Modern motherboards use like 10+ layers. Masks need to be made for each.endocine said:Would like to see this in the hands of the masses, so we all can design our own things, like motherboards, and have them manufactured at XXXway and other PCB outsources.

Oh, I'm sure you could already license UEFI source code from someone like AMI and fiddle with parameters to your heart's content. It wouldn't be cheap, but that would be the way to go.endocine said:Then another AI would write a customized EUFI.

AI isn't good at writing large software programs (yet). -

bit_user Reply

Presumably, what they did was train a neural network to create these designs, given inputs like the schematic and the physical constraints of the resulting board(s). Not sure how many such constraints you could place on existing board layout packages. It probably falls over pretty quickly, the more constraints you try to layer on.umeng2002_2 said:People need to be careful about using the term "AI."

Also, the fact that they're talking about a 2-board architecture could be highly significant. An existing PCB layout tool might not be able to figure out how to optimally partition the design across multiple boards.