Rapidus explores panel-level packaging on glass substrates for next-generation processors — aggressive plan would help it leapfrog rivals

Wedding glass and PLP ahead of others?

Rapidus, which positions itself as a vertically integrated chipmaker that offers both front-end semiconductor production and back-end packaging, plans to discuss its efforts in the field of panel-level packaging (PLP) on glass substrates at SEMICON Japan event this week, reports Nikkei. Panel-level packaging on glass substrates is among the most advanced chip packaging technologies that is set to emerge in the coming years.

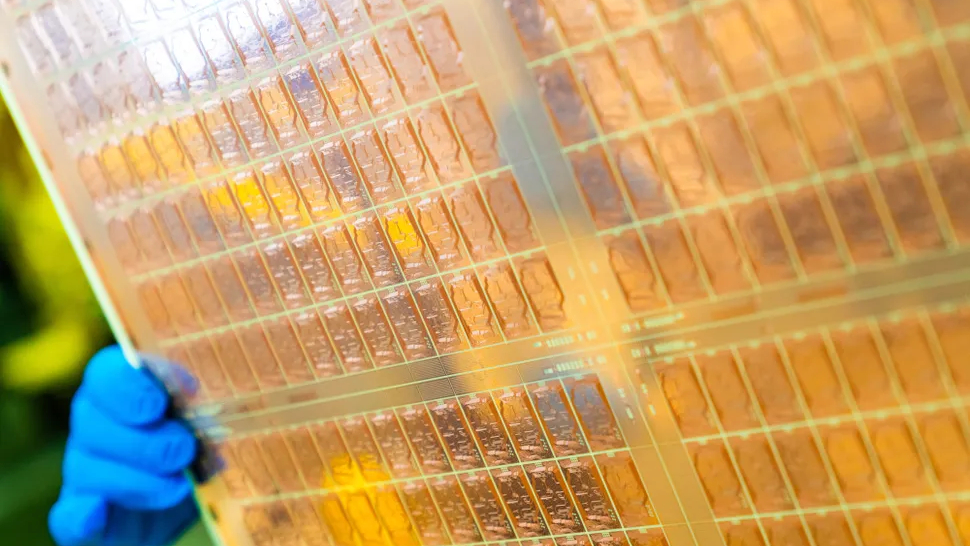

The core of Rapidus's development is 600mm x 600mm glass panels that are used to make substrates for high-end multi-chiplet processors, such as those used for AI and HPC accelerators. This means that Rapidus plans to leap ahead of its rivals using both panel-level packaging and glass core substrates, which is a risky, but perhaps necessary move, as the company only plans to offer leading-edge process technologies and the most sophisticated packaging technologies for customers who need them. The company has been experimenting with glass panels since June, so its PLP and glass-related efforts are at the very early stages.

Today's advanced packaging technologies (such as TSMC's CoWoS) rely on silicon interposers with fine-pitch redistribution layers (RDLs) and through-silicon vias (TSVs) that electrically connect GPUs and HBM stacks. Such interposers are processed on 300-mm silicon wafers using front-end–like semiconductor manufacturing steps, but after they are ready, they are placed on organic package substrates.

Silicon is used because it supports very high wiring density, tight dimensional control, and thermal expansion behavior that is designed to match logic and memory dies. However, properties of organic substrates sometimes do not match those of silicon interposers (limited wiring density, warpage at large sizes, weaker thermal and mechanical stability, etc.), which is why established players like AMD, Intel, and Samsung are exploring glass-core substrates for their next-generation packaging flows.

Glass-based substrates offer clear advantages over traditional organic materials, including excellent flatness that enables exceptional dimensional control, which is a key requirement for dense interconnects in advanced system-in-packages (SiPs) built from multiple chiplets. In addition, glass delivers stronger thermal performance and mechanical rigidity, enabling it to tolerate higher operating temperatures and harsher conditions typical of data center–class SiPs. As a result, glass substrates are particularly well matched for AI and cloud processor designs that tend to rely on large, complex, and thermally demanding multi-die packages. Yet, glass substrates are currently in development and are not in mass production.

Panel-level packaging refers to processing chip packages on large rectangular panels rather than round wafers, and today it is used mainly in fan-out panel-level packaging (FOPLP) for some automotive, power, RF, and wearable solutions, though they are not yet common. PLP offers clear advantages over 300-mm wafers: they can offer more efficient manufacturing and a larger package. However, currently, there are no higher-end semiconductor packaging tools that can enable front-end-like processing on panels. As a result, PLP for AI and HPC packages is still in the development stage at Intel and Samsung. That said, the ongoing work on glass-based panels suggests PLP could become viable in the late 2020s at the earliest, initially as a way to replace very large organic substrates and potentially complement (but not fully replace) silicon interposers in advanced AI system-on-chips (SoCs).

Meanwhile, Rapidus seems to plan to wed PLP with glass substrates from the very start, though it is unclear when it intends to do so. Nonetheless, Rapidus's ambitions to be ahead of the industry clearly highlight the company's aggressive plans to become a leading chipmaker right from the very start.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

cyrusfox PLP is the next step, packaging on wafers can't keep up with economics of scale of PLP. Only a matter of time.Reply