Laser Alters Color Of Metals, Creates Gold Aluminum

Rochester (NY) - Scientists at the University of Rochester have found a way to change the intrinsic surface properties of virtually any metal to achieve a change in color.

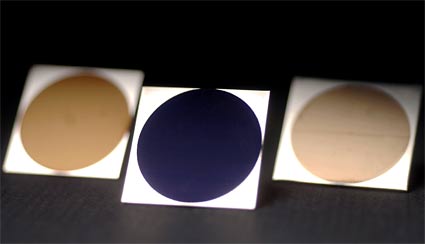

The new method apparently can yield virtually any color in any type of metal and create, for example, gold aluminum, black platinum, gray gold or blue silver. About one year ago, Chunlei Guo found that he could use intense laser light to render certain metals "pitch black"; now, he said he and his assistant Anatoliy Vorobeyv have become "determined to get full control on getting metals to reflect only a certain color and absorb the rest".

"We finally can make a metal reflect almost any color we wish," says Guo. "When we first found the process that produced a gold color, we couldn't believe it. We worked in the lab until midnight trying to figure out what other colors we could make."

Guo and Vorobeyv said they use an "incredibly brief but incredibly intense laser burst" that changes the surface of a metal, forming nanoscale and microscale structures that selectively reflect a certain color to give the appearance of a specific color or combinations of colors. This "femtosecond laser" uses light pulses lasting only a few quadrillionths of a second. Guo said that this laser "unleashes as much power as the entire electric grid of North America does, all focused onto a spot the size of a needlepoint."

The process isn't just a coating, but changes the surface of the material, which means that the color will not fade or peel, the scientist claims. Guo believes that his discovery will enable applications such as "a cycle factory using a single laser to produce bicycles of different colors; etching a full-color photograph of a family into the refrigerator door; or proposing with a gold engagement ring that matches the color of your fiancée's eyes."

To alter an area of metal the size of a dime currently takes 30 minutes or more, but the researchers are working on refining the technique.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Wolfgang Gruener is an experienced professional in digital strategy and content, specializing in web strategy, content architecture, user experience, and applying AI in content operations within the insurtech industry. His previous roles include Director, Digital Strategy and Content Experience at American Eagle, Managing Editor at TG Daily, and contributing to publications like Tom's Guide and Tom's Hardware.