UltraRAM scaled for volume production — memory that promises DRAM-like speeds, 4,000x the durability of NAND, and data retention for up to a thousand years, is now ready for manufacturing

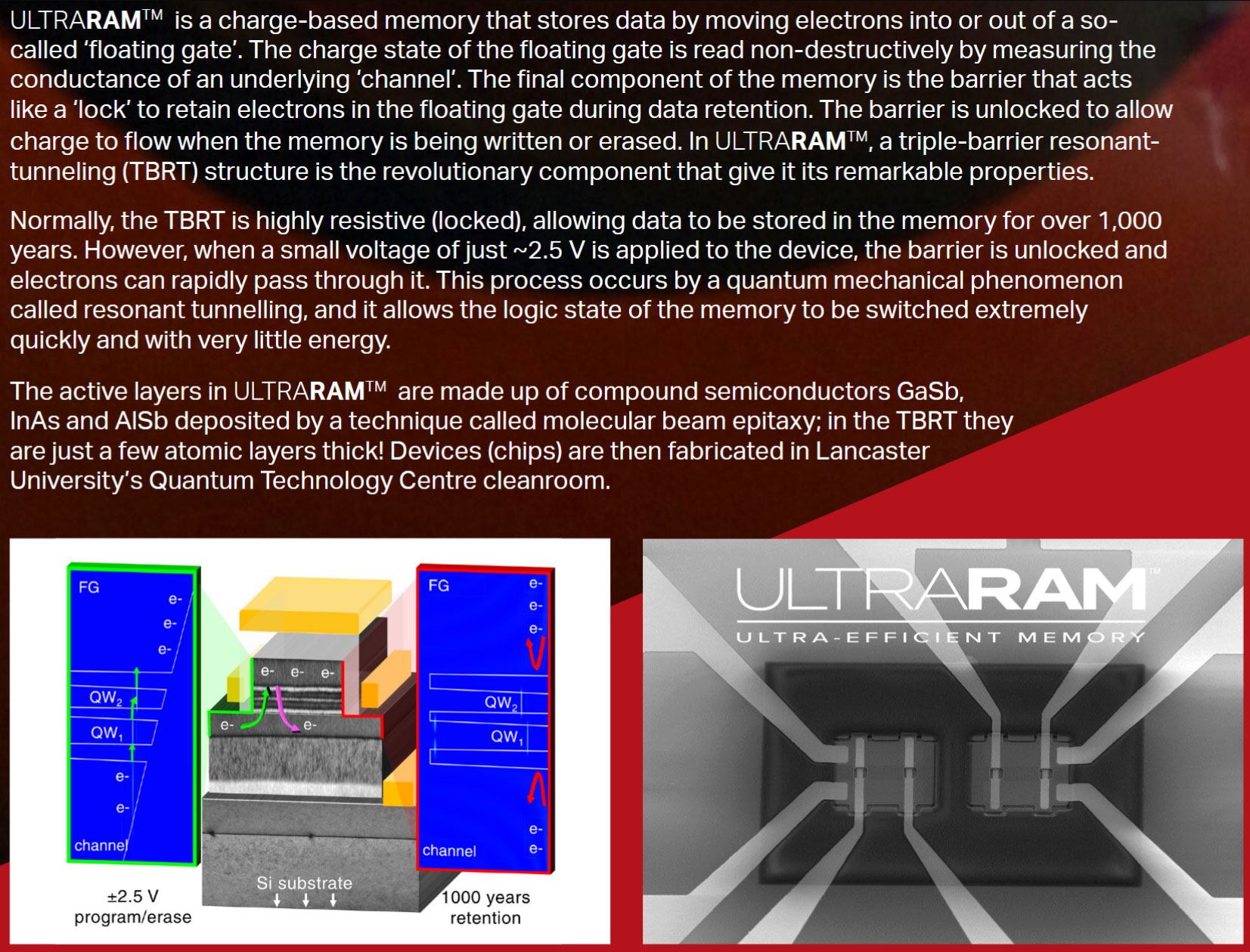

At the heart of the breakthrough is an advanced industrial process using gallium antimonide and aluminum antimonide epitaxy.

Efforts to commercialize UltraRAM have made significant strides forward. Quinas Technology, the firm behind UltraRAM, has been busy working alongside advanced wafer products maker IQE plc for the last year to scale UltraRAM memory device creation into an industrial process. According to Blocks & Files, the collaboration has been a success, and the memory that promises DRAM-like speeds, 4,000x the durability of NAND, and data retention for up to a thousand years is now on the cusp of production.

The design now benefits from the development of a new, advanced gallium antimonide and aluminum antimonide epitaxy process, claimed to be a world first, which will enable UltraRAM volume production.

UltraRAM is reliant on an epitaxy process, where compound semiconductor layers are grown with great precision on a crystalline substrate. Later, more familiar semiconductor production processes, such as photolithography and etching, are then applied to create the memory chip structures.

“We have successfully achieved our goal of developing a scalable epitaxy process for UltraRAM, a milestone towards industrial production of packaged chips,” Jutta Meier, CEO of IQE, said in a statement reproduced by Blocks & Files. “This project represents a unique opportunity to bring the next generation of compound semiconductor materials to life in the UK.”

A complementary statement, from Quinas CEO and co-founder James Ashforth-Pook, characterized the collaborative success as “a turning point in the journey from university research to commercial memory products.”

Next up on the commercialization roadmap, Quinas and IQE are said to be weighing pilot production with various foundries and other collaborators.

If you could cherry-pick the best qualities of DRAM and NAND…

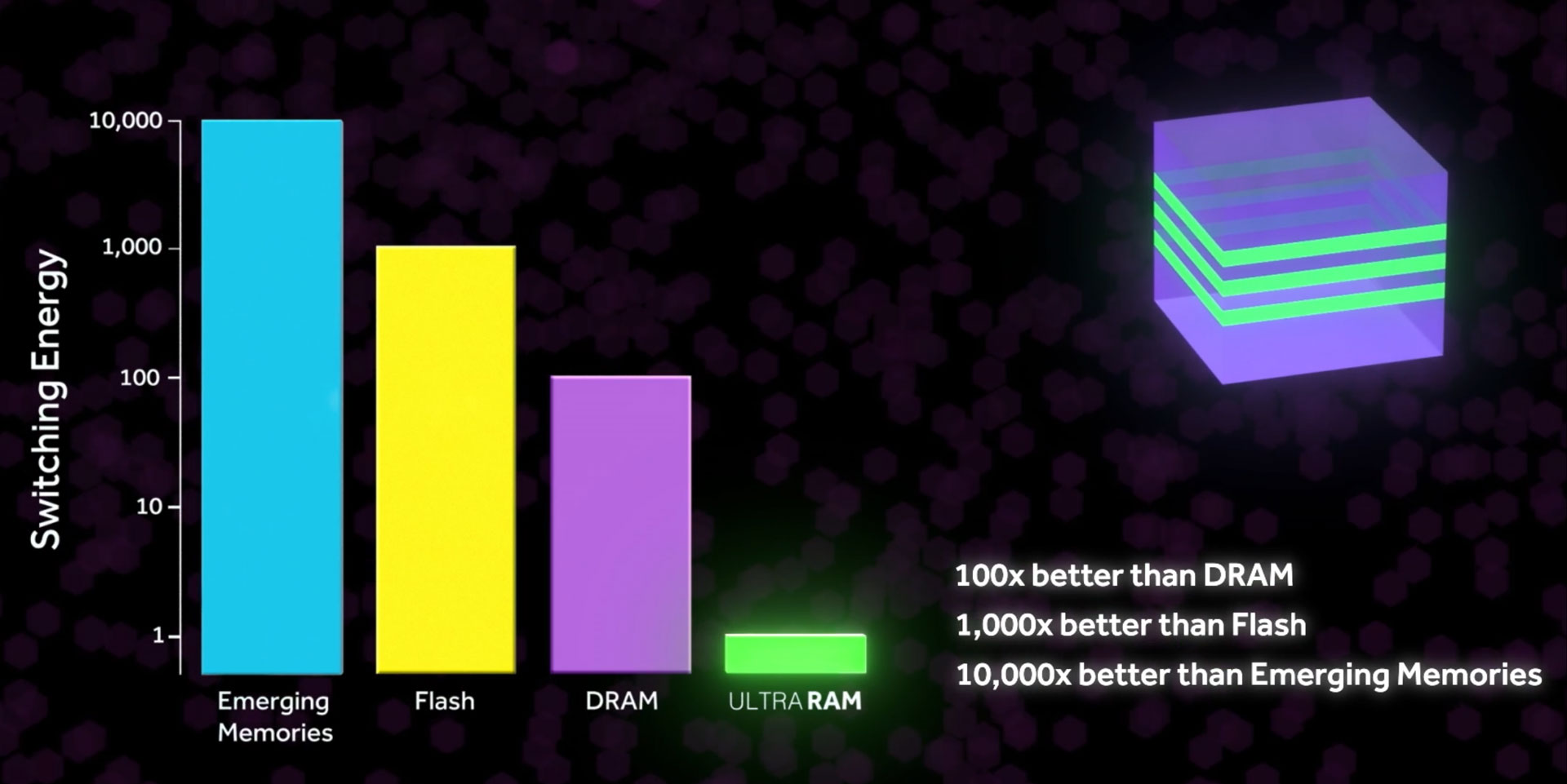

In case you haven’t been following the UltraRAM story, we first covered this new memory technology back in 2022. It boasted of many tantalizing ‘cake-and-eat-it’ attractions; DRAM-like speeds, <1 femtojoule switching, 4,000x the durability of NAND, and non-volatility for up to a thousand years. The patented tech would be the first memory to exploit a quantum-mechanical process called resonant tunneling.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

This was a fascinating technology to see in development. However, knowing the journey from blockbuster white paper to commercial production is a long, hard, and winding one, many thought it was yet another technology we wouldn’t hear of again.

In September 2023 we had the pleasure of visiting the UltraRAM labs, which had recently spun off from Lancaster University to be championed by Quinas Technology. There we were among the first members of the public to another milestone – a prototype UltraRAM memory chip in testing.

Now, things are getting really exciting with the headlining scaling of the UltraRAM fabrication process for volume production.

Follow Tom's Hardware on Google News to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button.

Mark Tyson is a news editor at Tom's Hardware. He enjoys covering the full breadth of PC tech; from business and semiconductor design to products approaching the edge of reason.

-

passivecool so... nobody knows what this actually means, yet.Reply

Nice though to see the Brits actually succeeding in something toward the virtue of world relevance which they have only long assumed. -

gg83 We saw how profitable 3D Xpoint worked out. I see zero profits. Maybe they will sell to some big company.Reply -

LabRat 891 Reply

3DXpoint had major issues that had nothing to do with the physical technology or manufacturing. Issues that Intel and all involved parties are (to this very day) *actively* keeping quiet about.gg83 said:We saw how profitable 3D Xpoint worked out. I see zero profits. Maybe they will sell to some big company.

This technology seems sufficiently "fundamentally different" in construction from Optane/3DXpoint to (hopefully) avoid most of Optane's problems. -

abufrejoval Hmm, I saw modular beam epitaxy mentioned somewhere in there, which means, yes, you can do ultra fine structures, but no, it's not lithography (fully parallel along two axis), but sequential, something that slows as transistor counts increase.Reply

Don't see fabrication being mentioned, which isn't a good sign... -

ezst036 Are they involved with JEDEC, plan to get involved with JEDEC, or will this evolve to become another Rambus/RDRAM situation that tries to hold all companies and all users hostage?Reply -

usertests 4,000x the durability of NAND = less than the effectively infinite write endurance of DRAMReply

It sounds like a replacement for 3D XPoint/Optane. Which is a great thing for some use cases. It would be much better if it killed NAND completely, but they'd be hyping other aspects if that was going to happen. -

Sam Hobbs The title says for volume production implying it is available now or very soon, yet the article seems to be saying it is still being researched. I think the title is intended to get our attention more than accurately communicate what the article is about.Reply -

jackt I dont like ram that keep the data...Reply

but i dont understand, it keep the data when the devices is shut down ? but powered ?

with no power ?

if unpowerd can be used as SSD ? -

Mr Majestyk Reply

All the benefits of NAND and DRAM, NAND is non-volatile and I take that as a pro not con.jackt said:I dont like ram that keep the data...

but i dont understand, it keep the data when the devices is shut down ? but powered ?

with no power ?

if unpowerd can be used as SSD ?