How Seagate Tests Its Hard Drives

Tom's Hardware gets a rare and in-depth look at how Seagate designs and tests its hard drives. Join us for a tour through the company's Longmont, Colorado R&D center.

Setting The Stage

Imagine spending vast resources on your profession, whether that's providing IT support services, making movies, raising kids, preparing the city’s finest food or steam cleaning carpets. People know what you do, and you do it every day. However, almost no one understands how you do what you do.

Why does this matter? If you provide IT services, by understanding your processes, potential customers will have a better sense of what fuels your expertise and dependability. After all, Google reviews only lend so much credibility, right? Anyone can claim to provide the best carpet cleaning. But you won’t believe those claims unless you understand the chemicals and equipment used.

The same holds true for hard drive manufacturers. Seagate spends $2 billion annually on R&D, not that you probably gave much thought to its investments when you bought your last multi-terabyte hard drive. The upside of this annual outlay is Seagate’s 1.2 percent annual failure rate. This is a company-wide average. Business drives will inevitably feature a lower AFR than consumer-class models. But saying, “Two billion USD buys better AFR numbers” doesn’t tell you much. We’re big believers in showing rather than telling.

To this end, we hired local photographer Noah Katz and packed our bags for beautiful early summer Boulder, Colorado. Seagate’s reputation as a close-to-the-vest, conservative company is well-founded. Very rarely does the drive behemoth open its doors to the press, much less at one of its four R&D centers (one is in Minnesota and another two are in Asia, although the Longmont, CO facility is the largest). So when senior staff in Longmont agreed to let us peek behind the glass curtain, we jumped.

A “sea gate” is a route or channel that gives access to the ocean, or, alternatively, that offers protection against the sea. In 1978, when the company (then called Shugart Technology) was founded, the exabyte-era metaphor of “the digital universe” had yet to become common. The “sea of information” prevailed. Hard drives, naturally, were set to become the conduit to this growing, seemingly limitless body of information. The nautical theme persists even now in the architecture of the Longmont R&D center, sporting a front edifice much like a ship’s rudder (or prow, depending on your perspective) and an interior bolstered with exposed beams.

Taking the metaphor to its drowning point, one could argue that Seagate’s Longmont center serves a similar function as the ocean faring explorers of centuries past. To tame those infinite storage seas, one must first chart a course. You don’t hear about most of the explorers who found their way to the ocean floor. Neither do you learn about all of the technology paths and drive designs that ended up in recycling bins. You simply enjoy getting more drive capacity for less money than ever before and chalk it up to the natural course of things—only there’s nothing natural about it. Breakthroughs require endless years of mind-bending, exhaustive work, not to mention one or two billion dollars in annual R&D.

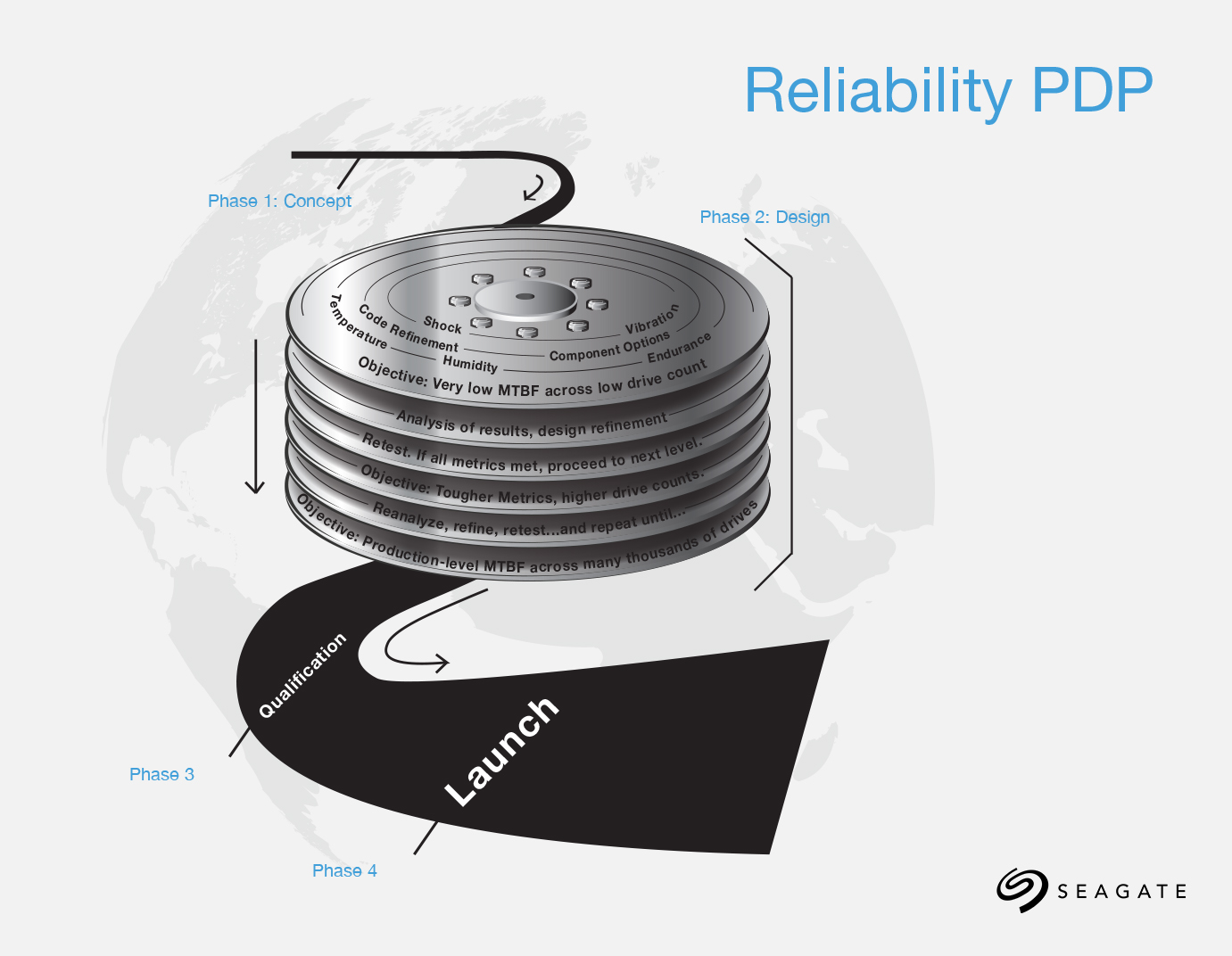

After 35 years of design launches and a dizzying chain of storage manufacturer acquisition and consolidation, Seagate sticks to its Product Development Process (PDP) like a holy play book. It works. PDP drive development breaks down into eight stages, as shown here:

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The focus of our infographic is on the Design phase, and this is where most of the Longmont center’s efforts lie. However, Longmont’s work actually begins earlier, in the Concept phase. During Concept, Seagate's marketing team works with customers to define product requirements, assess the market opportunity, and develop early proof of concept designs leveraging the company’s existing technology portfolio. After spending up to five years on road mapping and assessing technological and marketing feasibility, technology staging teams pass the baton to a “Core Team” to productize a drive design. The Core Team generates a contract agreement containing all of the key metrics the design must hit, covering specs such as power and performance, as well as a testing methodology that proves all metrics have been met or exceeded. This becomes the Core Team’s beacon to reach.

The Design phase delivers a working proof of concept drive. It’s almost a Bob the Builder question. “Can we build it?” Yes, we can. The resulting drive might be analogous to the Wright Brothers’ original Flyer, which never achieved flight for more than 59 seconds — but it worked.

During Design, the Core Team will either redesign a drive or leverage an existing drive design platform. Note that a drive design is not the same thing as a specific drive. A drive design is a base HDD architecture that can be leveraged to meet various market requirements. For instance, utilizing the drive design concept, a five-platter 4TB HDD design in the 3.5” form factor became the predecessor to a six-platter 6TB Enterprise Capacity 3.5 HDD. Engineers upped the disk count from five to six per drive, made minor improvements to the media design, changed the write head design, updated the nearline firmware code and so on. These were all iterative updates rather than a massive overhaul, but they were necessary to allow Seagate’s 7200 RPM drive line to evolve. Designs typically yield multiple drives and sometimes span multiple drive families, depending on how specific combinations of factors performed throughout development.

The core team’s journey begins in a room much like this one, where conferences and head-down concentration and collaboration can go on for over a year. The Core Team becomes like a second family, enabling tight idea flow and greater efficiency. It might seem strange that this Design phase in Longmont could stretch on so long, but the number of details that must be addressed when making even the smallest of design changes can be staggering. As a case in point, that transition from five disks to six ultimately required a complete redesign of the drive’s printed circuit board. Screw counts changed, chassis mounting hole locations moved, air recirculation filters and disk lubricants both had to be modified, and so on and so on, over painstaking months of analysis and simulation.

At last, after figuring out how a design could be achieved, then feasibility analysis determines whether the design should be achieved. For example, all other factors being equal, no one is going to buy a slower drive for the same price. The feasibility assessment must confirm that a design will meet the company’s profit requirements while still delivering products at an attractive price. If a new drive doesn’t offer some sort of compelling value for the company and customers alike, there’s no point in building it.

MORE: Best SSDs For The Money

MORE: How We Test HDDs And SSDs

MORE: All Storage Content

-

tom10167 Awesome photos. I don't know what the last picture is but I know I need one of those in my house.Reply -

Rookie_MIB ReplyAwesome photos. I don't know what the last picture is but I know I need one of those in my house.

That is an enterprise storage rack full of 2u hotswap chassis. 18 chassis, 12 drives per chassis = 216 drives @ 6tb (?) per drive = 1,296 terabytes or 1.3 Petabytes.

You could store a lot of TV shows or movies on that thing. Imagine how many of those are used for YouTube? Yikes. They get 300 hours of footage uploaded every minute. -

Mike-TH So if their testing is so good, why are their drives among the worst for reliability - to the point where most IT people I know actually refuse to use them, or if forced to use them will keep (and use) more spares than for other makers.Reply -

Tom20160027 The article explains the different types of drive/MTBF and why the backblaze test is useless information. Marketing plot to have folks talking about it and re-posting its link. It seems to work as we keep seeing the link over and over... They are not getting my data. They put drives designed for desktop into servers and run them to the ground and call it a "reliability test". Let's test my kids bicycle with training wheels at the Tour de France and complain about its quality....Reply

I know IT folks that refuse to use other brands of drives as well. I know IT folks that refuse to use servers from this brand or that brand. We can find anecdotal information about anything. It does not make it true. -

Glock24 Seagate tests their drives? I thought they didn't!Reply

I've had more Seagate drives die without warning than any other brand. The only ones that have survived are some old 250GB Barracuda ES. All other models I've owned had lots of bad sectors or just stopped working before the first year, but SMART almost always says the drive is fine! -

zodiacfml Yawn. All I think of right now is that HDDs will become the tape drives of the past.Reply -

Garrek99 The only drives I've ever had go bad on me were Seagate drives.Reply

Every other drive I've ever purchased simply became obsolete due to size and thus replaced.

They should be reading about how the other drive makers do their testing and learn from that. Hahaha -

rosen380 Maybe things changed... but all of my old SGI machines always had Seagate drives in them and the 20+ year old drives all still work. Hell look at what these drives *sell* for on eBay:Reply

http://www.ebay.com/sch/i.html?_sc=1&_udlo=0&_fln=1&_udhi=200&LH_Complete=1&_ssov=1&_mPrRngCbx=1&LH_Sold=1&_from=R40&_sacat=0&_nkw=%28st31200N%2C+st32171N%2C+st32272N%2C+ST34371N%2C+st34520N%2C+st34573n%2C+st39173N%2C+st318417N%2C+st52160N%29&_sop=16

4.5 GB drives *selling* for $150+ I see a 2Gb for $120.

They must have been pretty decent at some point if SGI was putting them in their $5000-20000 workstations and people are spending $40+ per GB to get these now...