Western Digital details 14-platter 3.5-inch HAMR HDD designs with 140 TB and beyond

HDDs for the current and next decade.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

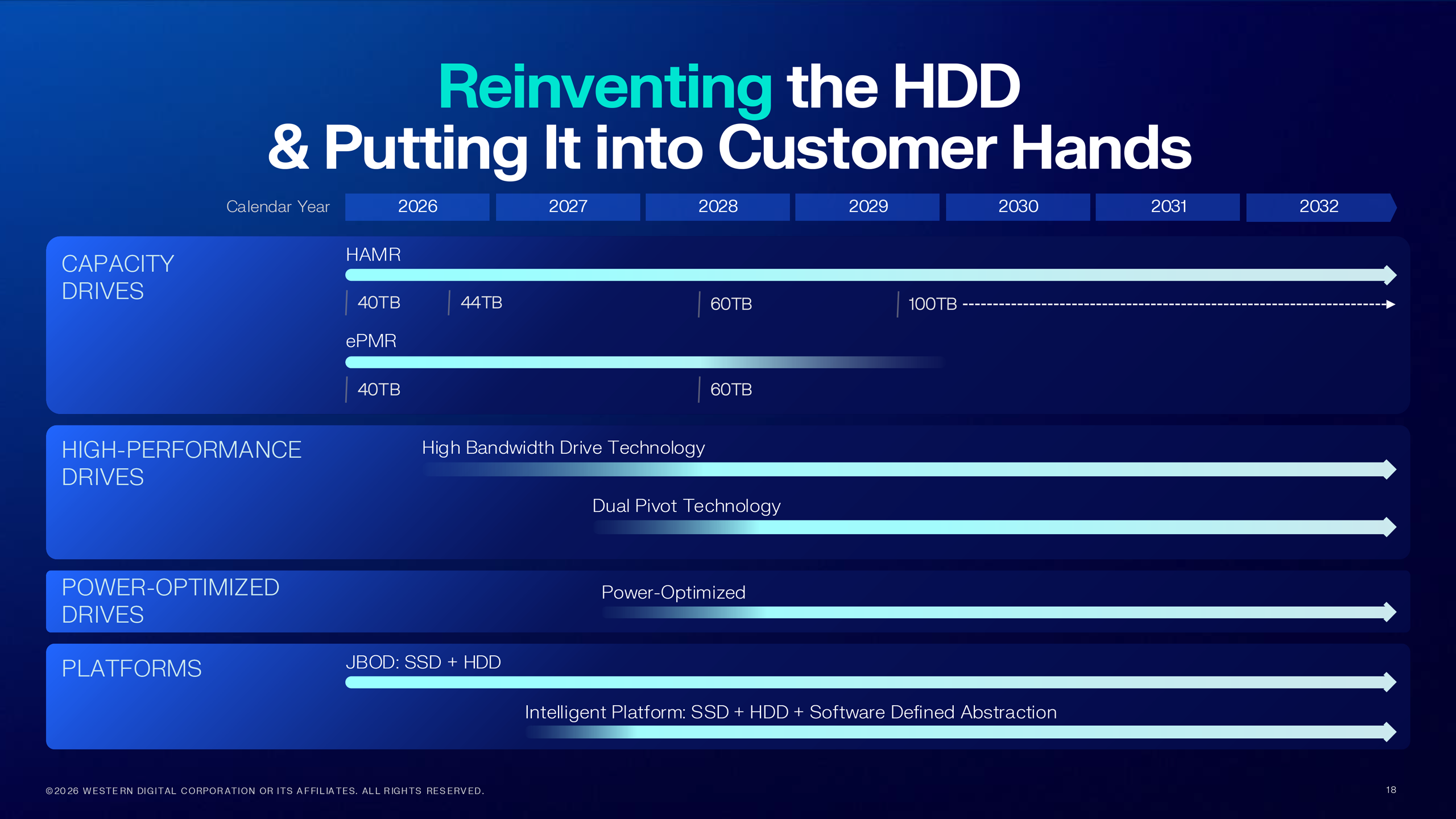

Western Digital this week outlined its near-term and mid-term plans to increase hard drive capacities to around 60TB and beyond with optimizations that significantly increase HDD performance for the AI and cloud era. In addition, the company outlined its longer-term vision for hard disk drives' evolution that includes a new laser technology for heat-assisted magnetic recording (HAMR), new platters with higher areal density, and HDD assemblies with up to 14 platters. As a result, WD will be able to offer drives beyond 140 TB in the 2030s.

Western Digital plans to volume produce its inaugural commercial hard drives featuring HAMR technology next year, with capacities rising from 40TB (CMR) or 44TB (SMR) in late 2026, with production ramping in 2027. These drives will use the company's proven 11-platter platform with high-density media as well as HAMR heads with edge-emitting lasers that heat iron-platinum alloy (FePt) on top of platters to its Curie temperature — the point at which its magnetic properties change — and reducing its magnetic coercivity before writing data.

New lasers

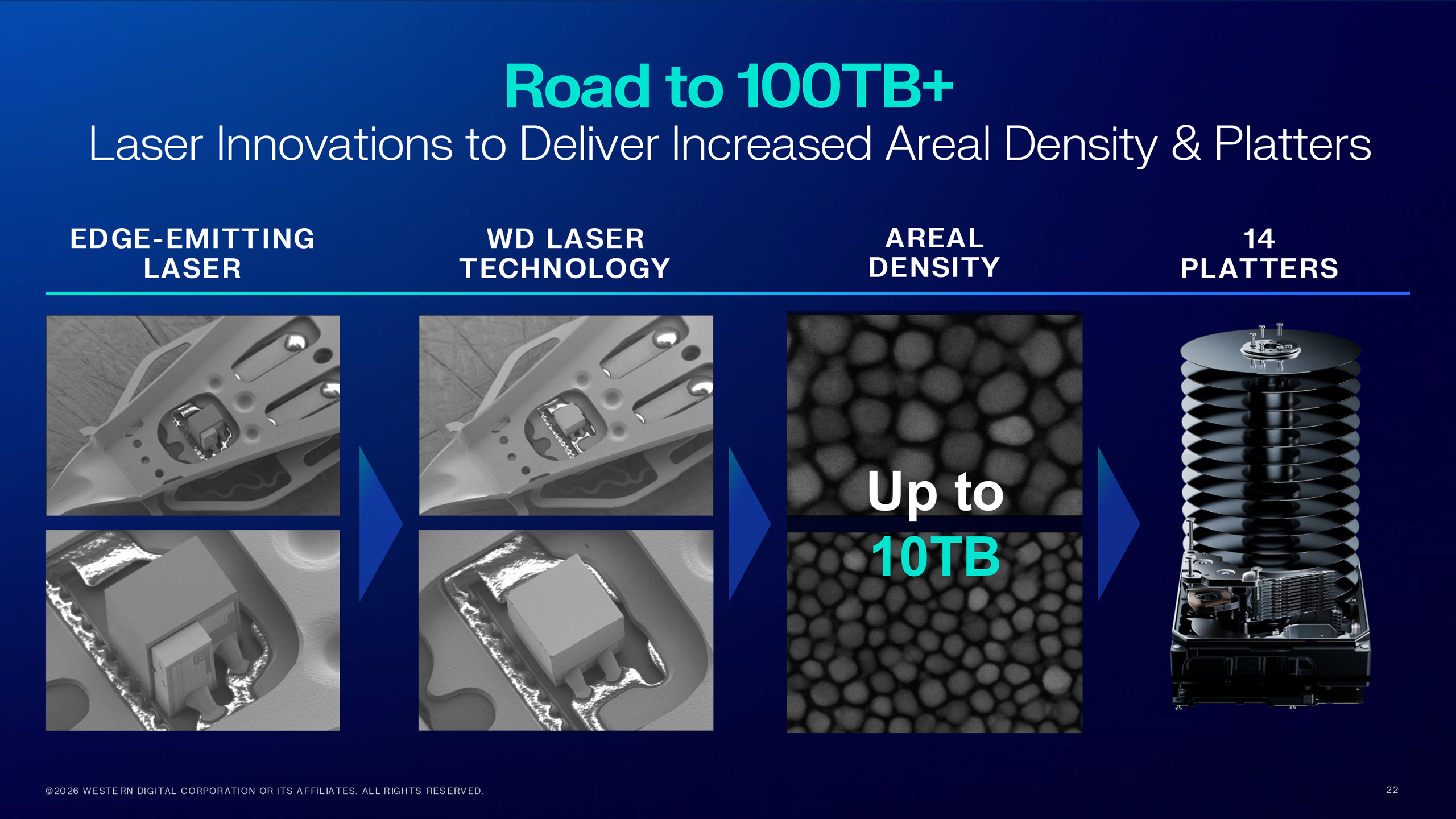

These edge-emitting lasers are efficient enough to make HAMR possible, but are mechanically and optically constrained, according to Ahmed Shihab, chief product officer at Western Digital. These lasers waste part of the generated light and are physically tall. That height forces additional spacing between platters, while optical losses limit how much thermal energy can be delivered to the media — both factors directly restrict areal density scaling.

More importantly, edge-emitting HAMR lasers are made with low yields as they rely on mechanical cleaving, precision optical alignment, and thermal screening, which prevents wafer-level testing. As a consequence, they can only be tested as part of the final head assembly, which greatly reduces yield (something that killed RDRAM years ago, as these memory chips must be tested only as part of the module assembly).

"Everybody in the industry, us included, use what is called an edge-emitting laser," Shibab said. "It is the gray box that you see sitting on the top [see the image above]. They work really well. They are the ones powering HAMR today, but they have three challenges. The light produced sometimes is wasted, so they waste a bit of energy that could be better used elsewhere. They’re quite tall, so we have to make sure the platters are some distance apart from each other. And during the hard drive manufacturing process, the yields are not as good as we’d like them to be."

To remove these limitations, Western Digital spent six years developing a patented vertical-emitting laser. Unlike conventional designs, it emits light straight down onto the magnetic media, couples more energy onto the disk, and is significantly shorter in the Z-dimension. This change enables two parallel advances: higher areal density (up from today's four terabytes per platter all the way to 10 TBs per platter) as well as a thinner head assembly that allows more disks to be packed into the same 3.5-inch drive. Furthermore, Western Digital's new vertical laser is made using a lithography process and can be tested on a wafer independently of the head, so the company also expects meaningfully higher manufacturing yields.

"By emitting more light, harnessing more of that light into the recording technology, we will increase the aerial density of the HAMR platters from four terabytes all the way to 10 terabytes by 2028 per platter," said Shihab. "This technology is not theoretical. It is actually already in the labs. We have watched it during the recording."

14 platters

Alongside its new vertical laser technology, Western Digital is also working on an HDD platform capable of housing up to 14 platters, another part of the equation enabling the company to increase the capacity of its hard drives significantly over the next 10 years or so.

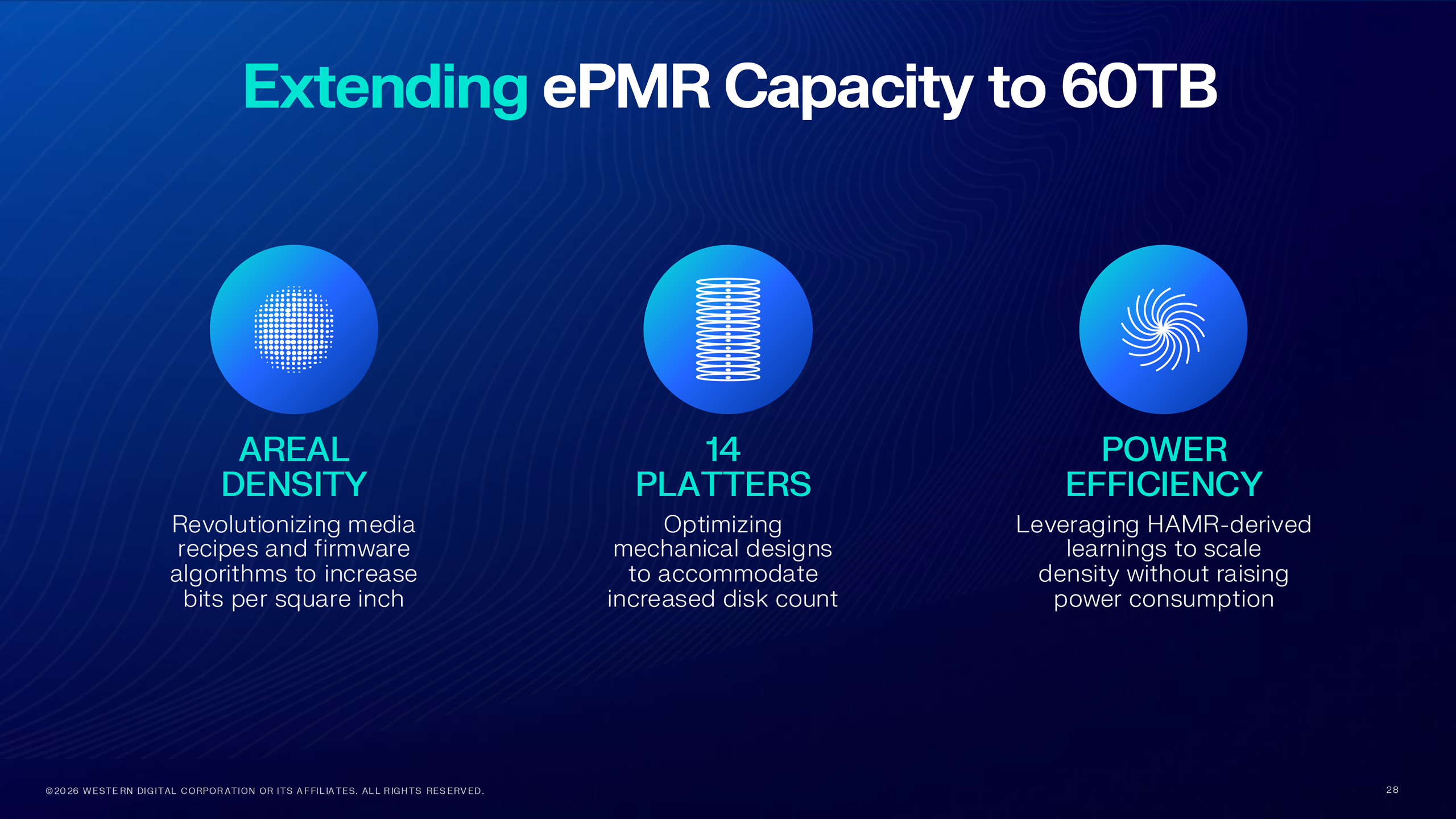

The 12-platter platform will first be used with 60TB ePMR drives in 2028. While Western Digital does not disclose how many platters the company's 60TB HAMR HDD will use, it says that its ePMR and HAMR drives will use the same platform, which suggests that HAMR products will also use generally the same design.

"We also borrowing some of the ideas from Hammer," said the CPO of Western Digital. "So, to get to 60, we will go to 12 platters. We are packing more capacity inside the same three and a half inch, all without changing the power profile of the drive. The customers don't have to spend more energy doing what we do."

Which is perhaps why Shihab carefully frames the new vertical laser technology not as a one-time capacity boost, but as a structural reset of HAMR's scaling curve that will aggressively grow starting in 2028 and is expected to enable 100TB HDDs in 2029 ~ 2030. In fact, once the vertical laser technology reaches its apex with granular media, sometime in the 2030s, Western Digital will be able to offer drives with an up to 140 TB capacity.

"10 terabytes, 14 platters, that sounds like 140 terabytes," Shihab teased.

Interestingly, but Western Digital's dual-actuator Dual Pivot HDDs that promise to double both bandwidth and sequential I/O IOPS performance also enter the scene at a 60TB capacity, though the company is tight-lipped whether these hard drives use ePMR or HAMR recording technology.

"Dual Pivot technology helps customers focus their software effort on improving more performance for AI versus having to deal with how the hard drives work," Western Digital's chief product officer said. "We will introduce this at the 60 TB mark. […] So we are starting to put High Bandwidth drive technology in our customers hands today [and] my biggest problem is finding them enough material so they can start testing. Dual Pivot technology will be in their hands in late 2027 and in 2028.

Beyond 140 TB per drive

After that 140 TB milestone (which is pretty contingent), the company will have to move on to ordered granular (OG) and eventually bit patterned media (BPM), which is when HDD disks will be patterned using highly sophisticated etching, nanoimprint lithography, e-beam lithography, or even photolithography.

With BPM, hard drive technology will be dealing with very localized heating, which must be controlled with extreme accuracy. Excess energy can disturb neighboring bits, while insufficient energy prevents reliable writes, which is why somewhere along the line, HDD makers will have to invent next-generation laser designs that will combine heating performance with extreme precision.

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.