AmeraLabs introduces elastic 3D printing resin with long-lasting squish — a full bottle is priced at $140

The flexible resin stays soft for months.

Flexible resins have a problem: printed pieces tend to harden over time, sometimes within just a few weeks. AmeraLabs, a European-based resin manufacturer, claims to have solved the problem.

"Most flexible resins are a compromise – they start soft but gradually harden over weeks or months," said Andrius Darulis, co-founder of AmeraLabs, in a press release. "We developed FLX-300 to maintain its properties over time. This opens up real engineering applications, not just temporary prototypes."

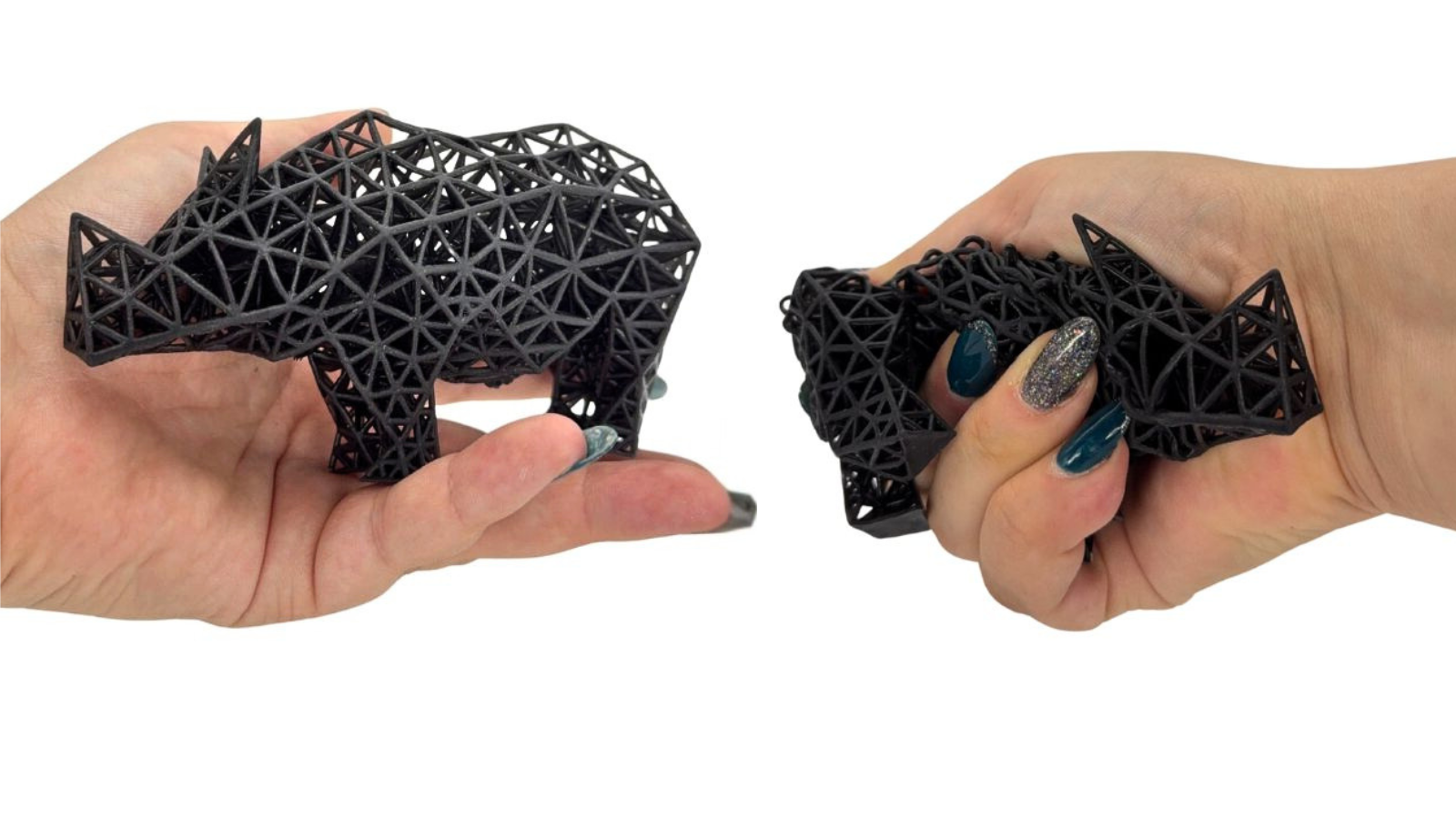

FLX-300 features an exceptionally low compression set, enabling printed parts to reliably spring back to their original shape after repeated deformation. AmeraLabs’ internal testing showed no measurable change after three months of aging, making it suitable for long-term use in engineering and functional applications.

The flexible resin is currently available for sale on the AmeraLabs website for €120 per 1KG bottle. That’s approximately $140 USD for a whole bottle, compared to $89 for AmeraLabs’ high-resolution TGM-7 resin, which is used for standard models. AmeraLabs requests that US customers shop their Amazon site due to customs laws, but the material is not yet in stock.

The material is only available in black and is ideal for printable gaskets, vibration dampers, and custom pieces that are expected to compress and spring back repeatedly. FLX-300 is reported to have low shrinkage, which contributes to its high dimensional accuracy. After post-curing, the material has a silky-smooth silicone feel.

AmeraLabs states that the new material also resists water absorption, maintaining stability in humid conditions, and cures to a non-tacky finish under standard UV light. It is compatible with a wide range of MSLA and DLP 3D printers, including those from Anycubic, Phrozen, Elegoo, Asiga, Epax, Longer, and Prusa. AmeraLabs cautions users not to employ PDMS-based resin trays, as the material is highly reactive and can damage silicone layers. The company recommends using fluoropolymer films such as FEP, PFA, or ACF instead.

For best results, AmeraLabs advises heating the resin to at least 25°C before printing and using slower lift speeds with well-braced supports. Because FLX-300 has a higher viscosity than standard resins, printed parts should not be left soaking in IPA or other solvents for more than 30 minutes.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

FLX-300 resin is not skin safe and should not be used for close contact with the human body or for any medical purpose. Technical data and printer settings can be found on the AmeraLabs website for your review before making a purchase.

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing. Denise has been crafting with PCs since she discovered Print Shop had clip art on her Apple IIe. She loves reviewing 3D printers because she can mix all her passions: printing, photography, and writing.

-

DiegoSynth It looks like a promising product, but at this price it's only luxury. Maybe it's ok for prototypes, but they need to lower these insane prices...Reply -

Taylor h it's not really that expensive for a revolutionary new product maybe it's a bit too expensive for the average person to use for making random pointless objects. they humidity state prototype and functional parts rather than novelty or entertainment purposesReply -

Psyk89 That's cool and all, but maybe you could add a reference in to an actual estimate of how long it truly stays elastic. It says "after 3 months" it stays elastic so it has applications for engineering and whatnot..but 3 months is definitely not a long enough timeframe to make a claim like that.Reply