Intel makes sharp reversal, is 'going big time into 14A,' says CEO Lip-Bu Tan — 'serve the customer well' remark hints at external client

Good news about 14A, it seems.

Although Intel's focus for this year's CES is to introduce its Core Ultra 3-series 'Panther Lake' processors and laptops, the company's chief executive, Lip-Bu Tan, still used the tradeshow to talk about 14A (1.4nm-class) process technology and reassure potential clients and investors that its development is proceeding well. The CEO's bullish statements marked a sharp reversal from his statements in July that the company would pause or discontinue the node if it didn't secure a customer.

"We are going big time into 14A," said Lip-Bu Tan in an Intel News video on X. "Stay tuned, we are going to see a lot of great momentum on the 14A in terms of yields [and] IP portfolio to serve the customer well."

Intel's 14A is expected to be production-ready in 2027, with early versions of process design kit (PDK) coming to external customers early this year. To that end, it is good to hear Intel’s upbeat comments about 14A. Also, Tan’s phrasing ‘the customer’ (plural) indicates that Intel has more than one client for 14A, implying that Intel Foundry will produce 14A chips for Intel Products and at least one more buyer.

Previously, Intel issued a warning that if it fails to gain at least one big external customer for 14A, it may 'pause or discontinue' its development, essentially leaving the leading-edge process technology race. From what we hear from Lip-Bu Tan now, it looks like the company has no plans to abandon or delay 14A development.

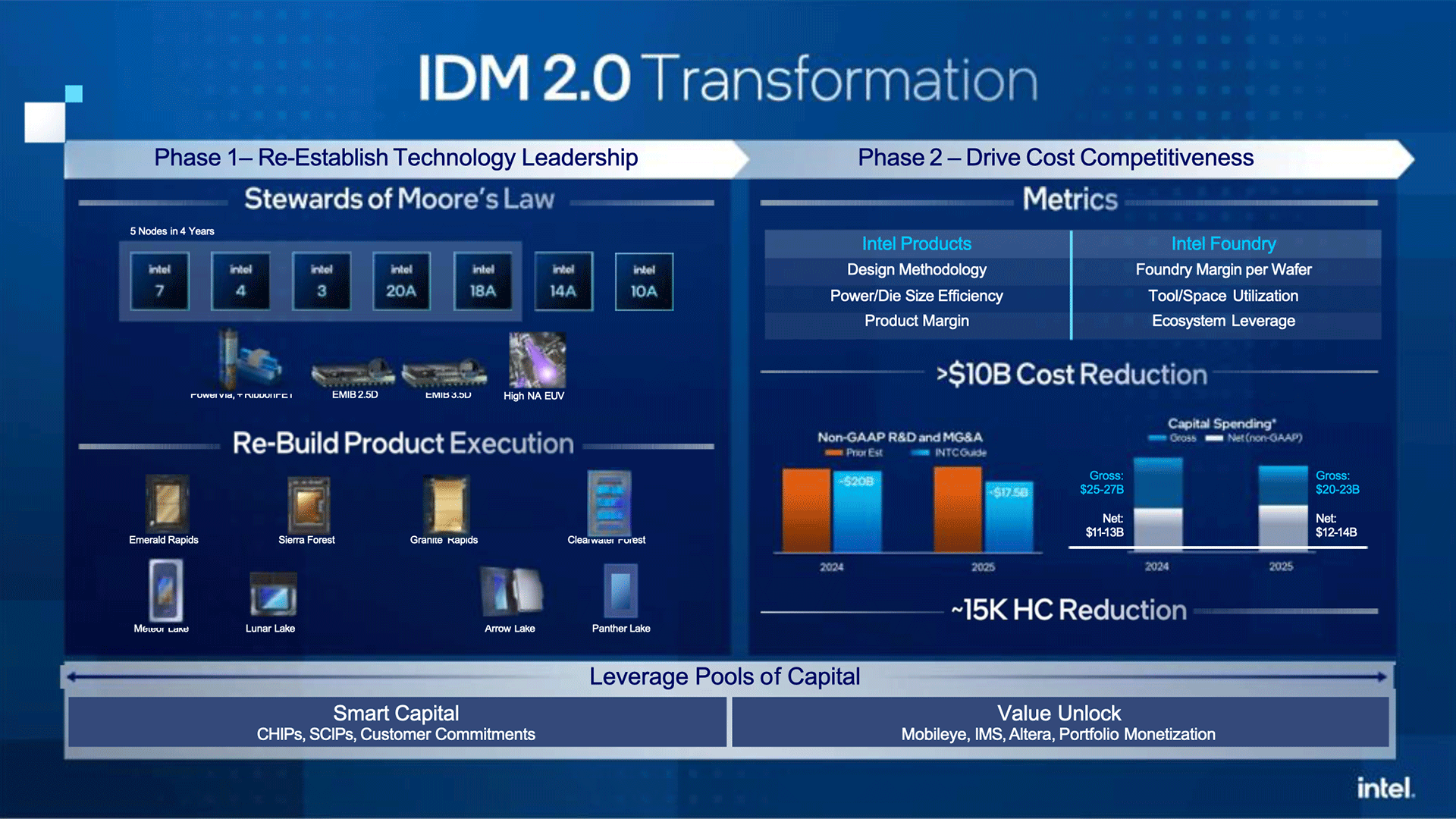

It goes without saying that Intel's 18A fabrication technology — which is used to make the compute tile of Panther Lake processors — is an important manufacturing process for Intel in the sense that it introduces gate-all-around (GAA) RibbonFET transistors and PowerVia backside power delivery network (BSPDN). However, 14A is by all means no less important because it builds on top of what the company will learn 18A. The 14A production node will introduce Intel's 2nd Generation RibbonFET GAA transistors; 2nd Gen BSPDN called PowerDirect that will connect power directly to source and drain of transistors, enabling better power delivery (e.g., reducing transient voltage droop or clock stretching) and refined power controls; and Turbo Cells that optimize critical timing paths using high-drive, double-height cells within dense standard cell libraries, which boost speed without major area or power compromises.

Yet, there is another aspect of Intel's 14A manufacturing process that is particularly important for the chipmaker: its usage by external customers. With 18A, the company has not managed to land a single major external client that demands decent volumes. While 18A will be used by Intel itself as well as by Microsoft and the U.S. Department of Defense, only Intel will consume significant volumes. For 14A, Intel hopes to land at least one more external customer with substantial volume requirements, as this will ensure that Intel will recoup its investments in the development of such an advanced node.

But there is a major catch. Intel's current capital expenditure (CapEx) plan does not include investments in 14A capacity for third-party clients. Hence, even if Intel lands an order from a major customer (think Apple, AMD, Nvidia, or Qualcomm), it will have to invest in additional capacity, which will delay Intel Foundry reaching the breakeven point.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

"When we win a customer for Intel 14A, we will have to layer on expenses well ahead of getting revenue," said John Pitzer, corporate vice president of corporate planning and investor relations at the RBC Capital Markets Global Technology, Internet, Media and Telecommunications (TIMT) Conference in November. "I do think for transparency purposes, as a sort of customer traction materializes, it is likely to push out that end. I am thinking though, most investors will be okay with that because it will be confirmation that we can actually stand up an external foundry."

Contract chipmakers typically discuss upcoming process nodes with customers before capacity exists and add capacity only after early adopters commit. At Intel, this model is different because the Products Group is the main customer, so capacity is built first to meet internal demand. This is especially critical for leading-edge fabs like those for Intel 14A, which require both Low-NA and High-NA EUV tools and other costly equipment. Given the enormous capital expense, foundries cannot afford idle assets, and normally ramp capacity only when utilization is well above 80% is guaranteed.

But offering a process node without available capacity to external customers risks undermining Intel's foundry ambitions. Competitors such as TSMC and Samsung Foundry typically expand fabs with multiple anchor customers already committed and expect additional demand to follow. Since advanced tools like EUV scanners have long lead times, Intel could miss key foundry opportunities if it cannot provide capacity for third-party clients on time.

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

JamesJones44 Seems to contradict what Tan said previously about not investing in further processes if they can't get customers. However, there could be some between the lines going on here, but I don't want to speculate for various reasons.Reply -

Gururu "Looking further ahead, we’re developing Intel14A as a foundry node from the ground up in close partnership with large external customers. This is essential to designing a process that meets specific customer requirements and enables us to address a broader segment of the market. Going forward, our investment in Intel 14A will be based on confirmed customer commitments. "Reply

Maybe they got some commitments, or just riding high on Panther right now. -

thestryker The real question I have is the fab strategy as not investing in finishing the fabs means they don't have as quick a turnaround for expansion. It does sound like there's plenty of space at Fab 52, but all of the High-NA machines they've gotten thus far are installed in Oregon. They can't afford to tie up Oregon to make volume production for long term so I'm hoping the next ones are installed in one of the two Arizona fabs. This would at least indicate they do have a large enough customer for volume production.Reply

The other variable of course is ASML's turnaround on EUV machines. Intel may not be able to get High-NA machines fast enough to absorb multiple high volume customers.

It still seems to me that Gelsinger's "if you build it they will come" was the right way to approach the fab space. That, however, is long term thinking which wall street is allergic to so I understand why it didn't fly. -

TerryLaze Reply

It also didn't fly because intel doesn't have infinite money.thestryker said:It still seems to me that Gelsinger's "if you build it they will come" was the right way to approach the fab space. That, however, is long term thinking which wall street is allergic to so I understand why it didn't fly.

They can't build up all the FABs they want to and then have them just sit there eating up money until maybe they get customers, they had to draw the line at some point.

If they have enough space for their own products then that will not only give them enough money for further expansion but also be a showcase for possible customers. -

shady28 I still think Intel should just focus on 18A now that they're there. Evolutionary incremental advancements. N2 / 18A are likely to be the cornerstones of everything for the next 3-5 years and I have a suspicion for much longer than that.Reply

The combination of cost getting on the upswing of a parabolic curve while performance improvements become increasingly minor is not something to look forward to. -

thestryker Reply

This isn't what happened though. They canceled everything that wasn't already being built and slowed down construction on everything being built other than Fab 52. The only thing Gelsinger put forth that is likely to happen is the Ohio fab and that's been delayed by at least 5 years.TerryLaze said:They can't build up all the FABs they want to and then have them just sit there eating up money until maybe they get customers, they had to draw the line at some point. -

thestryker Reply

Intel isn't retiring any of their EUV nodes that utilize industry standard PDKs any time soon (Intel 4 is done with MTL EOL, and 20A never happened everything else is staying). That means 14A will be it's own thing while they also further develop 18A. There's 18A-P which should be some time this year (unsure about productization timeline) which has updated GAAFET and BSPDN. Then there's also 18A-PT with TSV optimization to follow on from 3-T.shady28 said:I still think Intel should just focus on 18A now that they're there. Evolutionary incremental advancements. N2 / 18A are likely to be the cornerstones of everything for the next 3-5 years and I have a suspicion for much longer than that.

This is the biggest change for the company over where it used to be. There won't be retiring of these nodes since they're still volume viable, but they do need to continue advancing if they're actually going to be in competition for high margin fab business. -

EzzyB ReplyWhile 18A will be used by Intel itself as well as by Microsoft and the U.S. Department of Defense, only Intel will consume significant volumes.

I read somewhere... hmm started with a T?

T O

T O M'S

Something like that. Anyways it talked about Intel building something for some company..... Apple that was it. M series chips on something called 18A.

We read it here first...

Did we not? -

-Fran- I mean. They BETTER go big on 14A. This may be their last chance at keeping appearances of still being competitive with nodes manufacturing.Reply

Plus, isn't some of that CHIPS act money tied to delivering on 14A?

Regards.