ASML: Only 60% of Chipmaking Tool Orders Can Be Met This Year

Chip shortages set to persist.

As sales of chips are expected to total 427.7 billion units this year, semiconductors manufacturers are aggressively expanding production capacity and buying new equipment. Demand for lithography tools is so strong that ASML, the world's largest maker of scanners, is warning that only 60% of orders for deep ultraviolet (DUV) litho machines can be fulfilled.

"Although the current macroeconomic environment creates uncertainty, we believe the fundamental growth drivers remain intact," said Peter Wennink, chief executive of ASML, at the company's quarterly conference call with analysts and investors, per SeekingAlpha. "We continue to see unprecedented customer demand across all market segments, from both advanced and mature nodes. We are running at maximum capacity and expect demand to exceed supply well into next year."

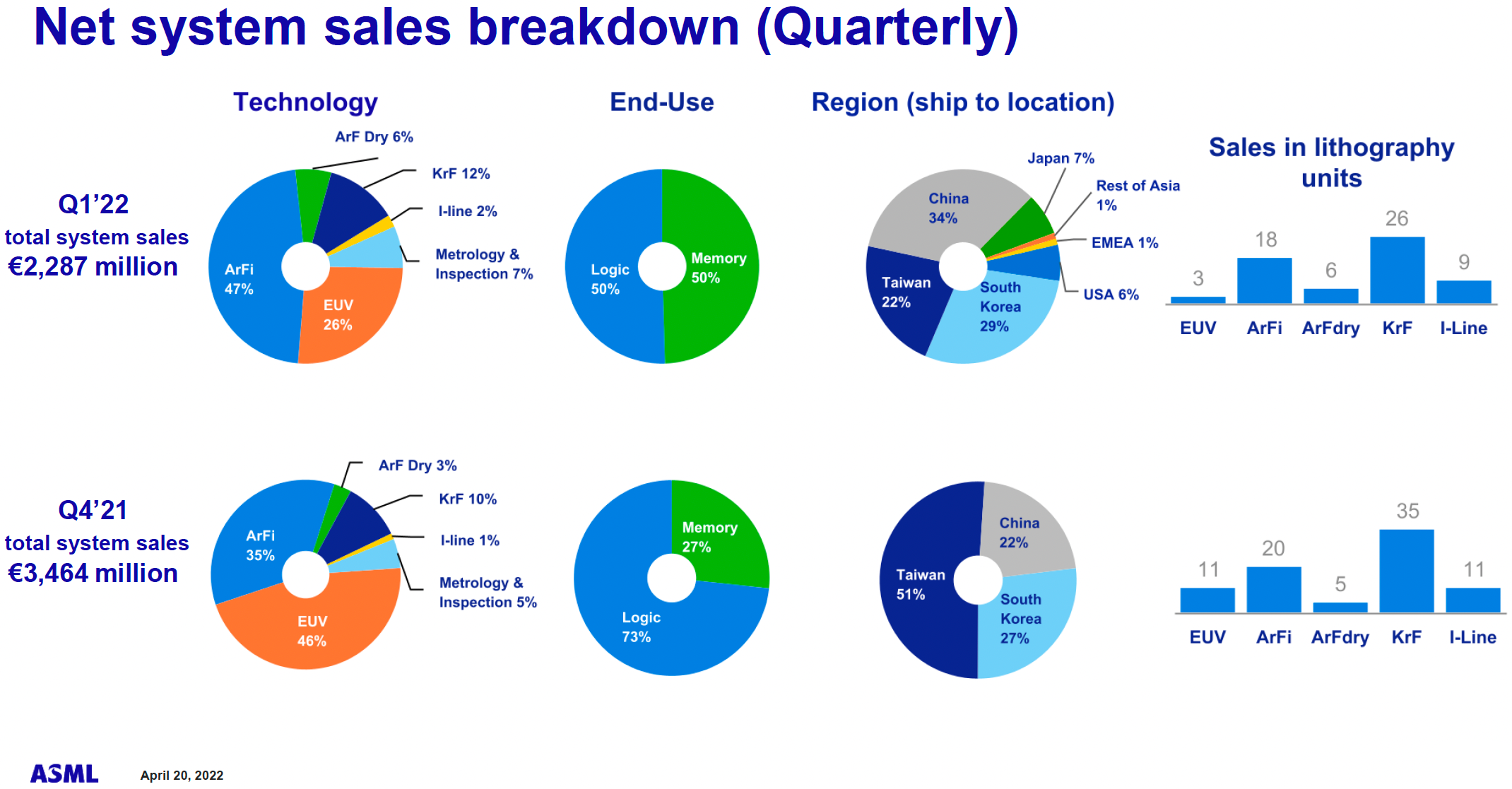

ASML plans to ship 55 extreme ultraviolet (EUV) scanners and around 240 DUV scanners this year (approximately 14 EUV and 60 DUV machines per quarter). Meanwhile, its backlog for DUV scanners presently is over 500 units, so product order lead time for a new DUV scanner (used to make chips using both mature and leading-edge nodes) is around two years now. Meanwhile, ASML stresses that product order lead time is irrelevant for now because to make more tools, the company needs additional capacity and extra time to build it.

"We can probably only ship at this moment in time, this year only 60% of the DUV demand," said Wennink. "So, anything that comes on that is driven by our maximum capacity. And anything beyond that, indeed, is a matter of capacity lead time, not the [product order] lead time."

ASML is working to increase its production capacity to 90 EUV 0.33 NA systems and 600 DUV systems (both immersion and dry) by 2025. It also intends to secure a capacity of around 20 EUV High-NA (0.55 NA) systems in the medium term.

Without a sufficient number of lithography scanners (and therefore production capacity), chipmakers will continue to undersupply for quarters to come.

For Q1 2022, ASML reported €3.5 billion net sales and €695 million net income.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

thisisaname I would have though the lead time on building the rest of the factory would mean there should be plenty of time to get the order in for the lithography tools.Reply

From plan to a stage where you want the lithography tools should be around 2 years, so this does not change much? -

InvalidError Reply

Depends on when during the entire fab planning process you wanted to place the order. You probably don't want to put the order in until you are 100% certain the site will be built and there is no chance of construction getting dropped for whatever reason, which could go a few months into construction. With the extra months lead time, if you want to be certain equipment will arrive on time, you may need to commit to a purchase before you even know whether all of the necessary construction permits will be granted.thisisaname said:I would have though the lead time on building the rest of the factory would mean there should be plenty of time to get the order in for the lithography tools.

From plan to a stage where you want the lithography tools should be around 2 years, so this does not change much? -

jp7189 In any other industry there would be competitors coming out of the woodwork to get a piece of the multi billion $ pie that ASML is leaving on the windowsill.Reply

Why does ASML have no competitors? Wizard magic? Aliens that want us to evolve but not too quickly? Seriously there nations that are be willing to burn unlimited resources to unlock the EUV secret. Why has no one else done it? -

InvalidError Reply

The same reason chip fabs are consolidating under 3-4 major corporations: the cost of independently making next-gen stuff has exceeded the amount of money any single company is willing to invest in their own process R&D, so the entire industry has consolidated its fundamental lithography R&D under ASML to avoid each having to spend billions re-inventing the DUV/EUV wheel and risking that whoever cracked EUV first would hold a death grip on the whole thing for the next 20 years.jp7189 said:Why does ASML have no competitors?

There is no meaningful competition for ASML because every major chip manufacturer owns a stake in ASML to spare themselves the trouble, costs and risks of competing on fundamental R&D. It is highly unlikely the established players would be willing to support another. If another one comes up, it'll be Russia-China going homebrew to bypass sanctions. -

thisisaname ReplyInvalidError said:Depends on when during the entire fab planning process you wanted to place the order. You probably don't want to put the order in until you are 100% certain the site will be built and there is no chance of construction getting dropped for whatever reason, which could go a few months into construction. With the extra months lead time, if you want to be certain equipment will arrive on time, you may need to commit to a purchase before you even know whether all of the necessary construction permits will be granted.

True but if your going to spend a few Billion on the fab, where it is may well depend on who is going to pay you the most give you the best financial package rather than getting planning permission.