Tesla's robotics ambitions rest on the knife-edge of US-China trade relations due to its supply chain — the majority of critical materials and suppliers are located in China

In a reversal of trade dynamics over cutting-edge silicon, China holds the cards in robotics manufacturing.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

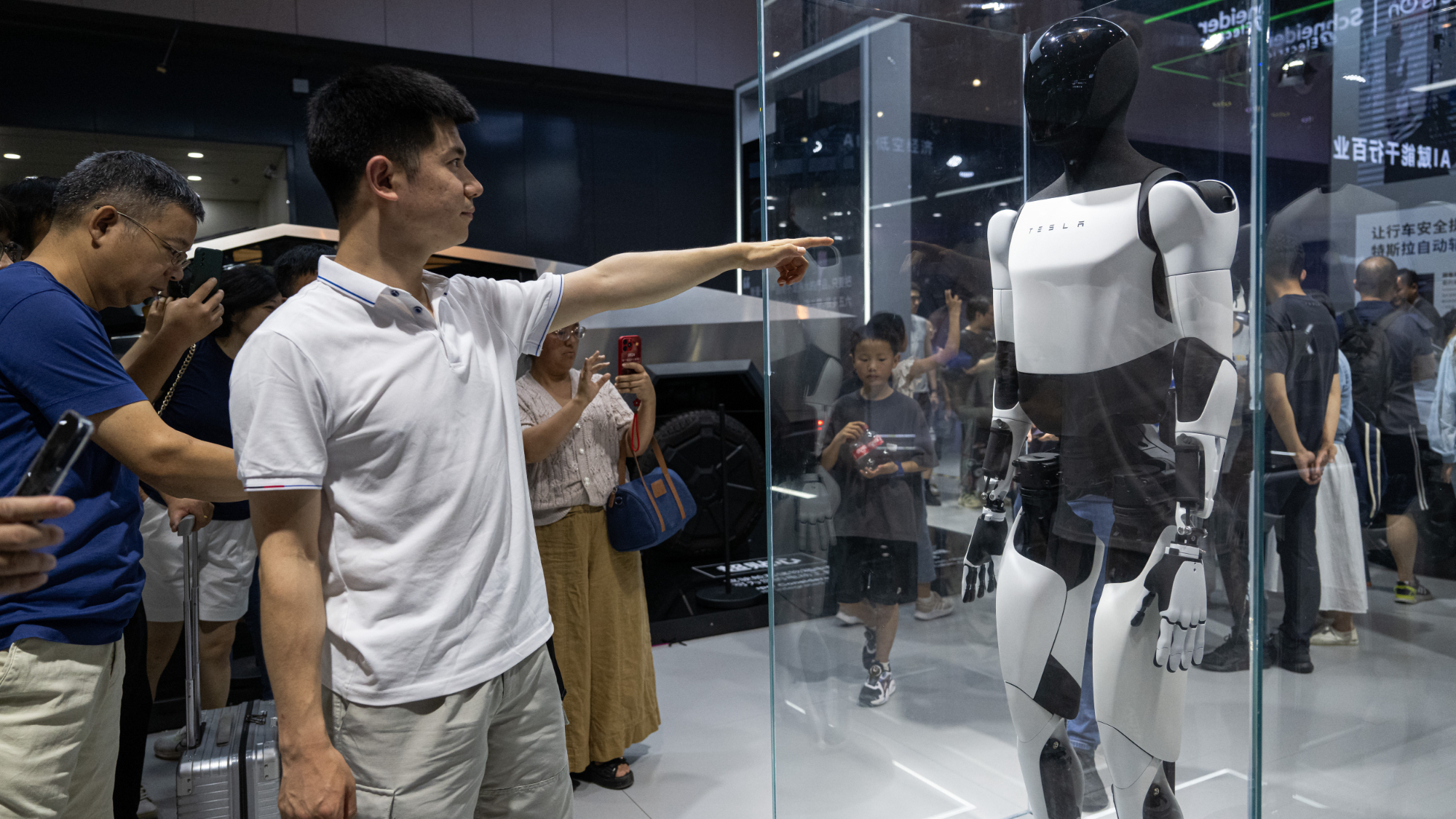

As Tesla begins its sudden pivot from an EV firm to a robotics and AI company, it's building out the supply chain it will need to reach its lofty goals of affordable humanoid robots that are manufactured at a rapid pace. But the scale of its production ambitions means it will need to rely heavily on the supply of raw materials, components, and manufacturing labor from China, as SCMP reports.

Tesla has a strong standing relationship with China, with its own Shanghai production facility that employs 20,000 people. It also sources many of the batteries for its vehicles from Chinese suppliers, and uses lots of raw materials in vehicle production sourced from China. China is also a major buyer of its vehicles, with over a third of all its sales in 2025 coming from China.

But the United States and China have spent the last year erecting and tearing down trade barriers. From America's side, the economic muscle came from its access to cutting-edge graphics cards and other chips used for AI training and inference. China's strength came from its manufacturing industry and access to raw materials, often termed "rare earths."

Although both are necessary for the AI industry to flourish, the ratio is much more lopsided when it comes to robotics. The "brain" of a humanoid robot will always demand impressive processing power and benefit from advanced AI software; the robots themselves demand an awful lot of critical materials. Many of those materials are mostly found in China.

While Chinese manufacturing and supply dominance affects all industries that produce just about everything, the scale of critical materials and manufacturing know-how necessary for next-generation robotics makes companies like Tesla incredibly dependent on the country.

The long list of must haves

Robots are complicated in ways that silicon and semiconductors aren't. Where chips are intricate and minute, and need clean room fabrication and specialized design software to even conceive of how they could be made, robots are decidedly more physical. Sure, they're technically advanced, but they're also made with iron, titanium, nickel, chromium, copper, and manganese. They use actuators, motors, bearings, and lubricants.

In short, they need a lot of stuff to make them, and a lot of that stuff comes primarily from China. Although key materials like Beryllium and Boron have strong supply chains within the U.S., China dominates the global supply of critical materials like Gallium (94%!), Zinc, Neodymium, Molybdenum, Indium, and Praseodymium, to name just a few.

It's not just the raw materials under the ground that's important, though. It's the expertise to extract it, the processing facilities to make it usable, and the logistical infrastructure required to get it where it needs to go.

“With about 50 to 70 per cent of manufacturing and core component production expertise residing in China, we expect Chinese players to take on greater roles in the global humanoid robot supply chain,” said Cheng Xin, a partner at US consultancy Bain & Co. “In some core components … they accounted for at least 55 per cent of the global humanoid robot bill of materials (BOM).”

China has enormous control over the supply of almost everything Tesla needs to build its next generation of humanoid robots. That puts it in an incredibly strong position, with the ability to curtail Tesla's ambitions whenever it likes.

China holds the cards

Unfortunately for Tesla, this has already happened. In April last year, Tesla CEO Elon Musk complained that a Chinese block on exporting "rare-earth magnets" had impacted production of the Tesla Optimus robot. He was forced to ask for a license to use them - perhaps an in-person visit would have helped.

China took all rare earth mineral resources within its borders under state ownership in the fall of 2024, so its leadership has the top-down control necessary to maintain tight controls on the supply of these kinds of critical materials well into the future. Although it has cut that supply outright to the U.S. several times during the ongoing trade negotiations with the Trump administration, it has since begun issuing limited export licenses to some companies.

The American government is aware of this chokepoint in its supply of such critical materials - many of which are also important for national security and the production of cutting-edge silicon - and is attempting to develop a new stockpile to provide a buffer against China's dominance. But even that $12 billion investment would only amount to a 60-day reserve, and its focus is on providing the necessary materials for civilian needs. In such a scenario where access to raw materials was cut off, Tesla would be forced to compete with many other firms and organizations that need those same materials.

Even beyond the risk of mercurial leadership threatening trade relations, China also has its own domestic humanoid robotics industry to consider. There are over 100 Chinese companies currently working on designs, and Chinese officials are making moves to centralize their development to accelerate progress and cut down on parallel research.

Chinese companies are already shipping consumer-grade robots, with over 13,000 deployed in 2025 alone. That's years of production ahead of the several hundred prototype Optimus models Tesla has made.

Just as BYD has overtaken Tesla in the EV space, China seems almost destined to get a huge head start in humanoid robotics over Western companies like Tesla. It already has more units in the world, its production is already higher, its access to key technologies and raw materials is better, and on tap.

Everything is close, efficient, and available. That's not something Tesla or other Western robotics firms can match.

And if China ever needed to slow down the competition, it could turn the tap off for those same supplies that are much harder to find anywhere else. Even if that didn't halt progression elsewhere, it would have a huge effect on pricing.

With Tesla hoping to get its Optimus down to $30,000 per unit in the future, the realization of that dream may be more down to China's whim than anything else.

Jon Martindale is a contributing writer for Tom's Hardware. For the past 20 years, he's been writing about PC components, emerging technologies, and the latest software advances. His deep and broad journalistic experience gives him unique insights into the most exciting technology trends of today and tomorrow.