Intel's Core i9-14900K Delidded: 12C Temperature Reduction

Power consumption dropped as well.

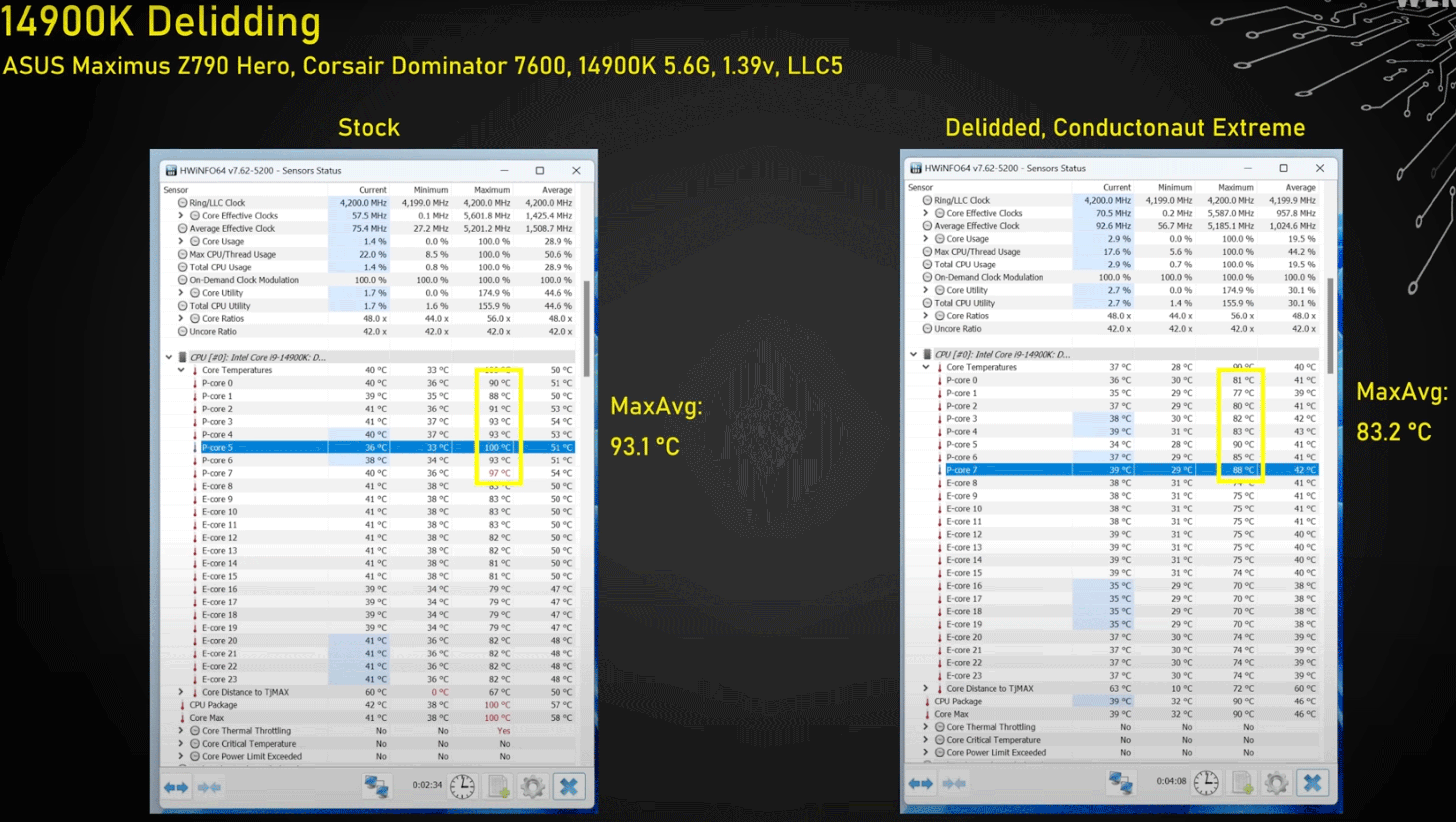

Renowned overclocker Roman 'der8auer' Hartung has delidded Intel's latest Core i9-14900K processor and applied liquid metal thermal paste to maximize thermal conductivity. This should cool down the CPU as much as possible without using exotic methods like liquid nitrogen. The experiment has proven that the difference between 13th Generation and 14th Generation Core CPUs is negligible, and delidding as usual results in a significant temperature reduction.

The delidding process was carried out using the Delid-Die-Mate tool produced by Thermal Grizzly, a company that works closely with der8auer. He them applied Thermal Grizzly's Conductonaut Extreme liquid metal thermal paste and used the CPU contact frame to maximize package uniformity and provide the best possible contact with Corsair's 360mm all-in-one liquid cooling system.

der8auer has proven with past experiments that delidding, accompanied by the application of liquid metal and the frame, leads to a substantial decrease in CPU temperatures and even power consumption (by around 10W) without compromising performance. On average, a 10°C reduction in average peak core temperatures and an 8°C decrease in E-core temperatures were observed with the 14900K, alongside a minor reduction in power consumption. Meanwhile, the removal of the IHS and application of a better thermal interface resulted in a maximum P-core temperature reduction of 12°C.

der8auer's findings further underscore the effectiveness of the delidding process, showcasing a significant improvement in thermal performance as evidenced by the reduced temperatures. The legendary overclocker said he did not expect such significant improvements because of delidding. However, Intel's 14th Generation Core i9-14900K processor is hotter than its direct predecessor, and that makes delidding a viable technique for enhancing thermal performance of this CPU.

Of course, delidding is also pretty risky and voids the warranty. It would be much better if Intel could improve the built-in heatspreader and other aspects of the chips for everyone, but for now this is something for enthusiasts who want to maximize cooling and performance.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

Crazyy8 All that money for 14900k, delidding, and thermal paste with an AIO on top for a 10C temp reduction and some saved power. With that amount of money I could get a good 7950X3D with a good cooler and still perform better. 14th gen not worth it.Reply -

-Fran- Reply

In fairness to Intel, it's still a better look than AMD's craptastic IHS keeping the cores all warmed up.Crazyy8 said:All that money for 14900k, delidding, and thermal paste with an AIO on top for a 10C temp reduction and some saved power. With that amount of money I could get a good 7950X3D with a good cooler and still perform better. 14th gen not worth it.

The same person, der8auer, showed the ludicrous difference for Zen4-based Ryzen 7000 CPUs when delidded.

That being said, I do like both AMD and Intel will have their hands forced when they try to push even more power on the new chips, since thermals are just going to push back (and bite) really hard.

Regards. -

TerryLaze Reply

It was an overclocked system with an all core of the p-cores to 5.6Ghz...and the temps before delidding where still 93 degrees average...Crazyy8 said:All that money for 14900k, delidding, and thermal paste with an AIO on top for a 10C temp reduction and some saved power. With that amount of money I could get a good 7950X3D with a good cooler and still perform better. 14th gen not worth it.

You don't need to delid, but he is an overclocker that sells overclocking equipment so he makes overclocking content.

Upcoming gen for both of them is going to be a new node wich means less power for the same performance, or more likely more performance but at least for the same power.-Fran- said:That being said, I do like both AMD and Intel will have their hands forced when they try to push even more power on the new chips, since thermals are just going to push back (and bite) really hard.

Also 5.6Ghz all p-cores and still 93 degrees, so intel still has some temp overhead to play with. -

Phaaze88 Reply

It hasn't clicked yet that temperatures like this are ok, but clueless personal feelings are getting in the way of that.TerryLaze said:Also 5.6Ghz all p-cores and still 93 degrees, so intel still has some temp overhead to play with.

I'm going to end up busting my head open from all the facepalms caused by 'temps too high' threads. -

zachacox Intel engineers are missing out on a huge opportunity, and it seems they don't even know it.Reply

What would happen if some desktop parts arrived already delidded, or more accurately UNlidded? Subbing a piece of plastic to ensure contact for the obviously higher cost of the lid and whatever garbage Intel uses to secure the lid and act as TIM wouldn't just save end users money, it would save Intel, too!

I'd certainly limit this idea to K and KF parts, as buyers of those SKUs are much more likely then non K buyers to want to delid, have the technical knowledge required, and/or know what advantage delidding even promises. Not only that, but Intel already recognizes that set of end users by not including an OEM HSF with K and KF SKUs.

In the age of buzzwords like 'sustainability' and 'carbon footprint', such a move has the potential for a bigger effect than first realized.

1. Labor and energy is spent manufacturing lids, transporting lids, receiving lids and committing lids to inventory. Same with glues and TIM materials.

2. Labor and energy is spent picking inventoried lids and other materials and then mounting them onto dies to create finished products.

3. Finished products are then shipped to distributors and resellers for shipment to end users, each leg of the process consuming more energy because of the weight of metal lids, as opposed to plastic contact plates.

4. A delidded or UNlidded CPU draws 10 watts less power, so says the foregoing, which means each of those million CPUs has the potential to save up to 88 kWh of power per year by itself.

5. Each of those UNlidded CPUs then dumps 10 watts less heat into the rooms they are in, which equates to 10 watts less air conditioning required to cool the rooms.

6. Those 10 watts plus the several additional watts to cool said rooms, plus the cost of transmitting those watts to the place of consumption may cost the end user a very small amount of money on a monthly or even yearly basis, but at ~120 kWh/year, over a 10-year lifespan that money is not trivial, especially when expressed in terms of TCO on a P&L statement.

7. Those 120 kWh must come from somewhere, and even if they come from renewable sources, they serve to offset other uses for that power, which in 2023 still usually means more generated by the use of fossil fuels. That in itself engenders a whole other discussion centering on extraction, transport, supply, demand and the economics thereof, plus the actual burning of and subsequent dumping of CO2 from them into our air.

Phew.

If Intel sells a million K and KF CPUs, and each lid weighs 25 grams more than a plastic piece, that equates to 25 million grams, or better said, 25 metric tons of weight that doesn't require energy to transport every step of the way. Those million CPUs could collectively save 1200 million kWh over a decade, more/less. That's just gotta be enough to send one DeLorean back to 2015. -

edzieba Reply

Large losses from RMAs due to cracked dies.zachacox said:What would happen if some desktop parts arrived already delidded, or more accurately UNlidded? -

leclod This article is wrong.Reply

The cpu wasn't just delidded, it was delidded and relidded.

The only difference was the kind of liquid metal. He replaced Indium with Gallium.

The Contact Frame was changed finally and only did account for 1.5° improvement.

(I have no idea why he does this or where the improvement came from, probably the heatspreader ends up closer the die) -

coozie7 Reply

Been wondering why they have n't tried this.zachacox said:Intel engineers are missing out on a huge opportunity, and it seems they don't even know it.

What would happen if some desktop parts arrived already delidded, or more accurately UNlidded? Subbing a piece of plastic to ensure contact for the obviously higher cost of the lid and whatever garbage Intel uses to secure the lid and act as TIM wouldn't just save end users money, it would save Intel, too!

I'd certainly limit this idea to K and KF parts, as buyers of those SKUs are much more likely then non K buyers to want to delid, have the technical knowledge required, and/or know what advantage delidding even promises. Not only that, but Intel already recognizes that set of end users by not including an OEM HSF with K and KF SKUs.

In the age of buzzwords like 'sustainability' and 'carbon footprint', such a move has the potential for a bigger effect than first realized.

1. Labor and energy is spent manufacturing lids, transporting lids, receiving lids and committing lids to inventory. Same with glues and TIM materials.

2. Labor and energy is spent picking inventoried lids and other materials and then mounting them onto dies to create finished products.

3. Finished products are then shipped to distributors and resellers for shipment to end users, each leg of the process consuming more energy because of the weight of metal lids, as opposed to plastic contact plates.

4. A delidded or UNlidded CPU draws 10 watts less power, so says the foregoing, which means each of those million CPUs has the potential to save up to 88 kWh of power per year by itself.

5. Each of those UNlidded CPUs then dumps 10 watts less heat into the rooms they are in, which equates to 10 watts less air conditioning required to cool the rooms.

6. Those 10 watts plus the several additional watts to cool said rooms, plus the cost of transmitting those watts to the place of consumption may cost the end user a very small amount of money on a monthly or even yearly basis, but at ~120 kWh/year, over a 10-year lifespan that money is not trivial, especially when expressed in terms of TCO on a P&L statement.

7. Those 120 kWh must come from somewhere, and even if they come from renewable sources, they serve to offset other uses for that power, which in 2023 still usually means more generated by the use of fossil fuels. That in itself engenders a whole other discussion centering on extraction, transport, supply, demand and the economics thereof, plus the actual burning of and subsequent dumping of CO2 from them into our air.

Phew.

If Intel sells a million K and KF CPUs, and each lid weighs 25 grams more than a plastic piece, that equates to 25 million grams, or better said, 25 metric tons of weight that doesn't require energy to transport every step of the way. Those million CPUs could collectively save 1200 million kWh over a decade, more/less. That's just gotta be enough to send one DeLorean back to 2015.

Years ago most CPUs came without a heatspreader, maybe it's

time to go back? -

coozie7 Reply

Possibly, but don't forget CPUs used to come without a heatspreader.edzieba said:Large losses from RMAs due to cracked dies.

The larger, more complex parts made now may very well be too vulnerable

to damage to be suppled ' bare ' but if that was the case, why can so many

seemingly delid and direct die cool? -

bill001g Reply

As was kinda said in a post above. His business is primarily selling the contact frames/delidders/various pastes. He also needs some kinda of content for his weekly video. I suspect he had nothing better to talk about since everyone has fully covered that the 14th gen is not all the special.leclod said:This article is wrong.

The cpu wasn't just delidded, it was delidded and relidded.

The only difference was the kind of liquid metal. He replaced Indium with Gallium.

The Contact Frame was changed finally and only did account for 1.5° improvement.

(I have no idea why he does this or where the improvement came from, probably the heatspreader ends up closer the die)

There really is nothing new to see here. If you want to go to the trouble of delidding and risk using liquid metal it will likely run cooler. Even he admits that the contact frames only help on some combinations of coolers and motherboard.

Not sure why toms linked this video it wasn't really any unexpect information.....then again this site and their freelance authors need to produce content also and the 14th gen has not been much to talk about.