Micron to begin work on $100 billion New York 'megafab' imminently — landmark site to produce 40% of company's overall DRAM output in the U.S. by the 2040s

Fab to finally break ground next week.

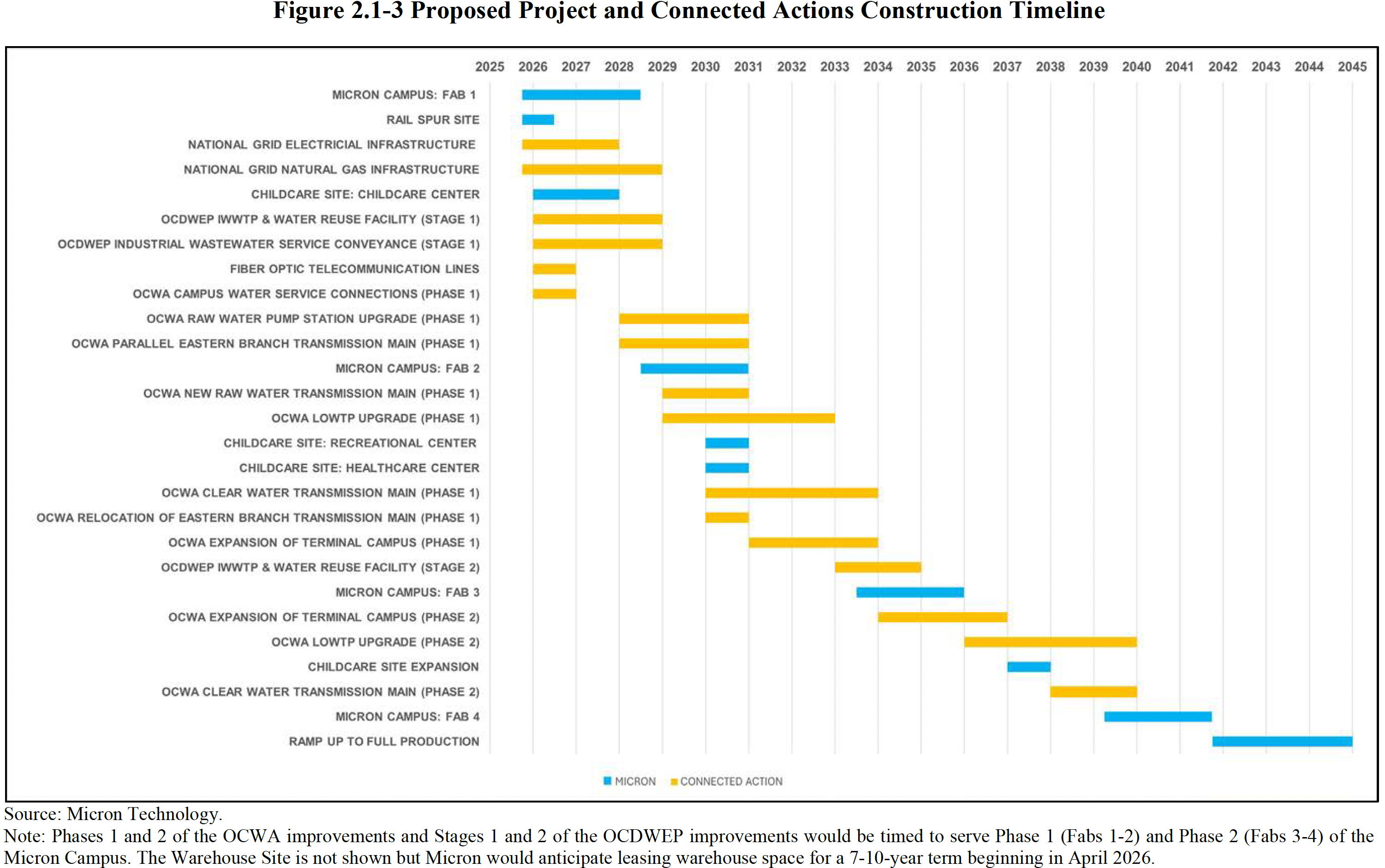

Micron this week announced that it would formally break ground on its fab site in Onondaga County, New York, on January 16. When fully built, the new site will house four fab modules and will cost around $100 billion in total. All four fab phases are scheduled to be completed by 2041, according to the company. The site will be an instrumental part of Micron's plan to build 40% of its DRAM output in the U.S. by the 2040s, up from virtually 0% today.

Five years of reviews and approvals

Micron's fab complex near Clay, New York, will be the largest semiconductor production facility in the state, as well as one of the largest fab complexes in the U.S., which will also outpace the company's site in Idaho when fully operational. In addition, $100 billion represents the largest private investment in the state ever, and one of the most expensive semiconductor manufacturing operations in America.

The groundbreaking ceremony to be held next Friday follows rigorous environmental review and necessary permit approvals, which has taken Micron around five years, something that delayed the whole project by around half a decade. Surprisingly, the groundbreaking ceremony precedes ground preparation, which is a rather unique situation. Normally, groundbreaking follows ground preparation, not preceding it. Yet, ground preparation will start more or less in-line with the schedule that the company outlined in 2025.

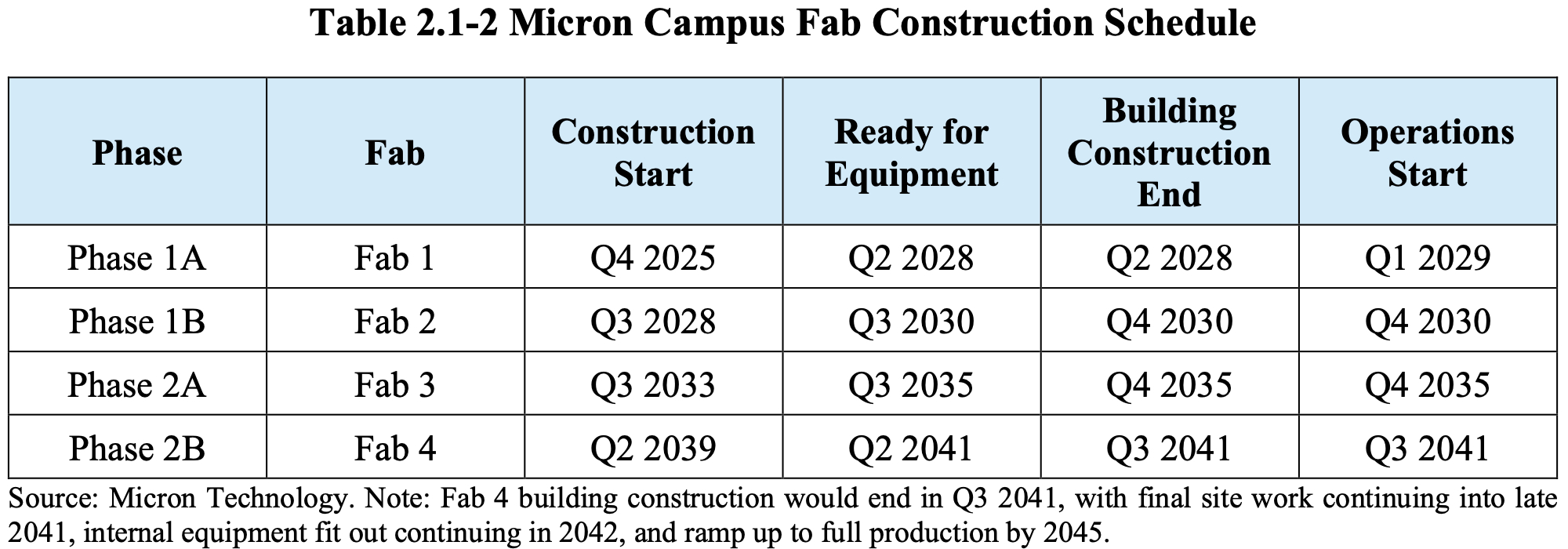

Micron's Environmental Impact Statement (EIS) filing, published in November 2025, indicates that Fab 1 site preparation was set to start in late 2025, but was obviously delayed by several weeks. The construction of the first facility is now set to begin in late 2026, and will run through Q2 2028. Given that equipping a fab typically takes nine to 24 months (depending on how you count), Micron expects the fab to start operations as early as Q1 2029. However, it will still take some time before the fab is fully equipped and ramped, so expect tangible DRAM output from Micron's New York Fab 1 by 2030, around five years later than originally planned.

The same documents schedule Fab 2 to break ground in the second half of 2028, Fab 3 in the second half of 2033, and Fab 4 in the first half of 2039. As a result, Micron's fab site near Clay, New York, will reach its full build-out and volume production by 2045, again, roughly five years behind the original timeline.

A long road ahead

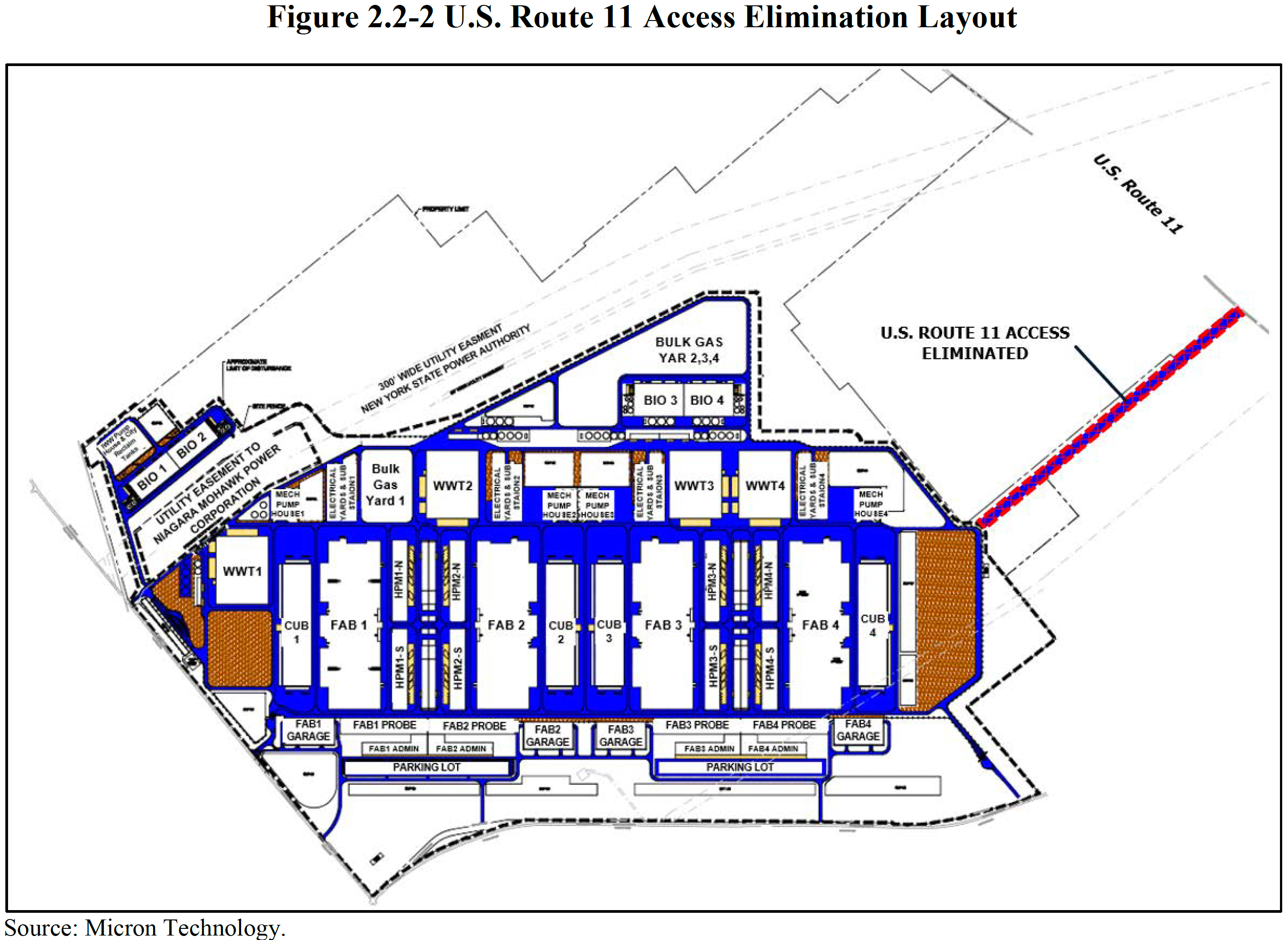

Micron's new campus in New York will manufacture DRAM using advanced process technologies and is ultimately planned to feature four fabs with four cleanrooms of 600,000 square feet (55,700 m²) each, constructed in four major build-out phases.

To put the 600,000 square feet number into context, GlobalFoundries Fab 8, located in Malta, New York, has a cleanroom space of approximately 460,000 square feet (though this is set to expand). The initial fab will cost around $20 billion, with successors expected to cost more, as Micron adopts more Low-NA EUV tools (priced around $235 million per unit) and eventually High-NA EUV tools (circa $400 million per unit) for its process technologies.

The New York complex will complement Micron's new site near Boise, Idaho. Last year, construction of the first new fab in Idaho (ID1) was completed, and the facility is now projected to begin wafer output in the second half of 2027. The company is also hard at work in its efforts to speed up the completion of its fab ID2, which will be built adjacent to ID1, benefiting from shared infrastructure and R&D co-location. It is projected that ID2 will start mass production of DRAM ahead of New York's Fab 1, though no further details are known.

Micron's wafer fabrication facilities near Boise, Idaho, will be adjacent to the company's R&D center, so will adopt the latest process technologies and will benefit from short feedback loops between the fab's process-integration teams and R&D personnel nearby. Such close collaboration will likely enable faster time-to-yield, which will improve Micron's profitability.

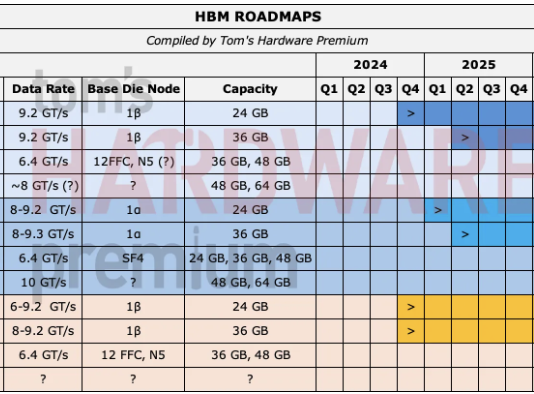

The close collaboration between process-integration and R&D teams will be particularly instrumental given Micron's current focus on high-capacity enterprise-grade DDR5 for servers and high-bandwidth memory (HBM) for AI accelerators. Both types of products tend to consume large DRAM dies, so rapid yield improvement is particularly important for these kinds of applications, as larger DRAM dies are expensive to make.

The grand plan

Right now, Micron has five wafer production facilities globally: two 3D NAND fabs in Singapore, a DRAM fab in Japan near Hiroshima, and two DRAM fabs in Taiwan (near Taichung and near Taoyuan). In addition, the company has an HBM packaging facility in Singapore, plans to build another fab module in Japan, as well as an HBM assembly plant in the U.S.

Given that the HBM packaging facility in Virginia is expected to come online after Micron ramps up production of HBM memory devices in Idaho, expect it to begin assembling HBM5 or HBM6 stacks towards the end of the decade.

Micron's grand designs include building 40% of its DRAM output in the U.S. by sometime in the 2040s. To achieve this, Micron plans to invest around $150 billion in six fab modules in America through 2045, as well as spending an additional $50 billion on R&D over the same period. However, it is unclear whether $50 billion will be spent exclusively in the U.S. (which will be a major boost for the American semiconductor industry) or whether it will be spread across Micron's R&D facilities across the world.

In any case, Micron's groundbreaking ceremony in New York next week will mark a key landmark in the company's expansion in the U.S. as well as a major milestone in the broad return of DRAM production to America.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.