Segotep's Titanload 12V-2x6 cables use heavier-duty pins to prevent meltdowns — brute-force approach purportedly drops peak temps by up to 72%

As the 12VHPWR power connector and its 12V-2x6 successor continue to plague the best graphics cards with meltdowns, Segotep, a Chinese manufacturer of computer hardware, believes it has a potential solution. The company's latest Titanload 12V-2x6 power cables (via Uniko's Hardware) incorporate power pins with higher current ratings, which could serve to prevent such connector failures.

PCI-SIG and Intel's ATX 3.0 specifications mandate a minimum electrical current rating of 9.2A for the power pins within the 16-pin power connector. Segotep's Titanload and Titanload EX power cables employ 12A and 14A power pins, respectively. These ratings deliver safety margins that are 30% and 52% higher than the reference specification. Additional advantages of employing higher-amperage pins include enhanced heat dissipation and improved capacity to contain current imbalances during spikes.

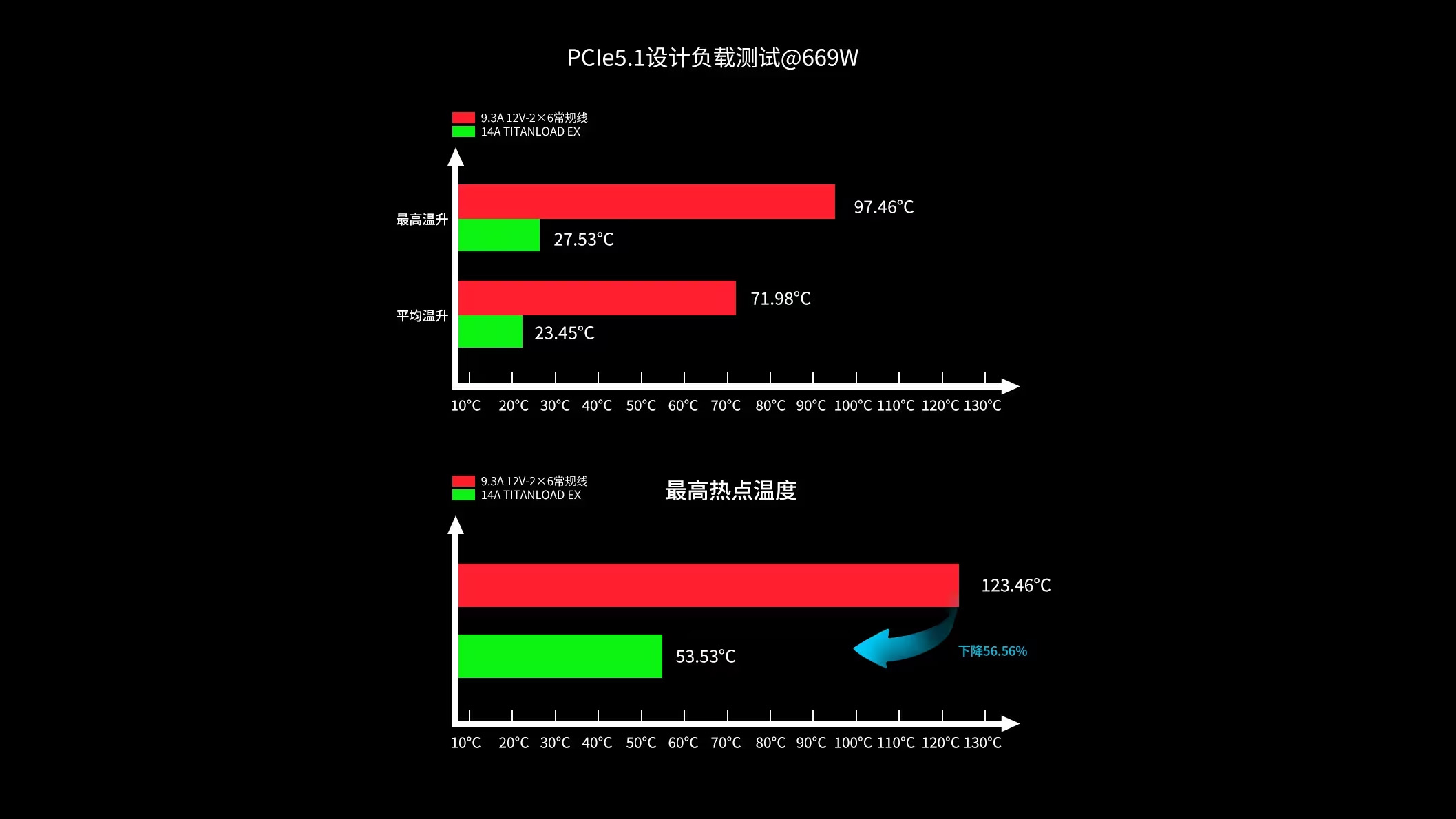

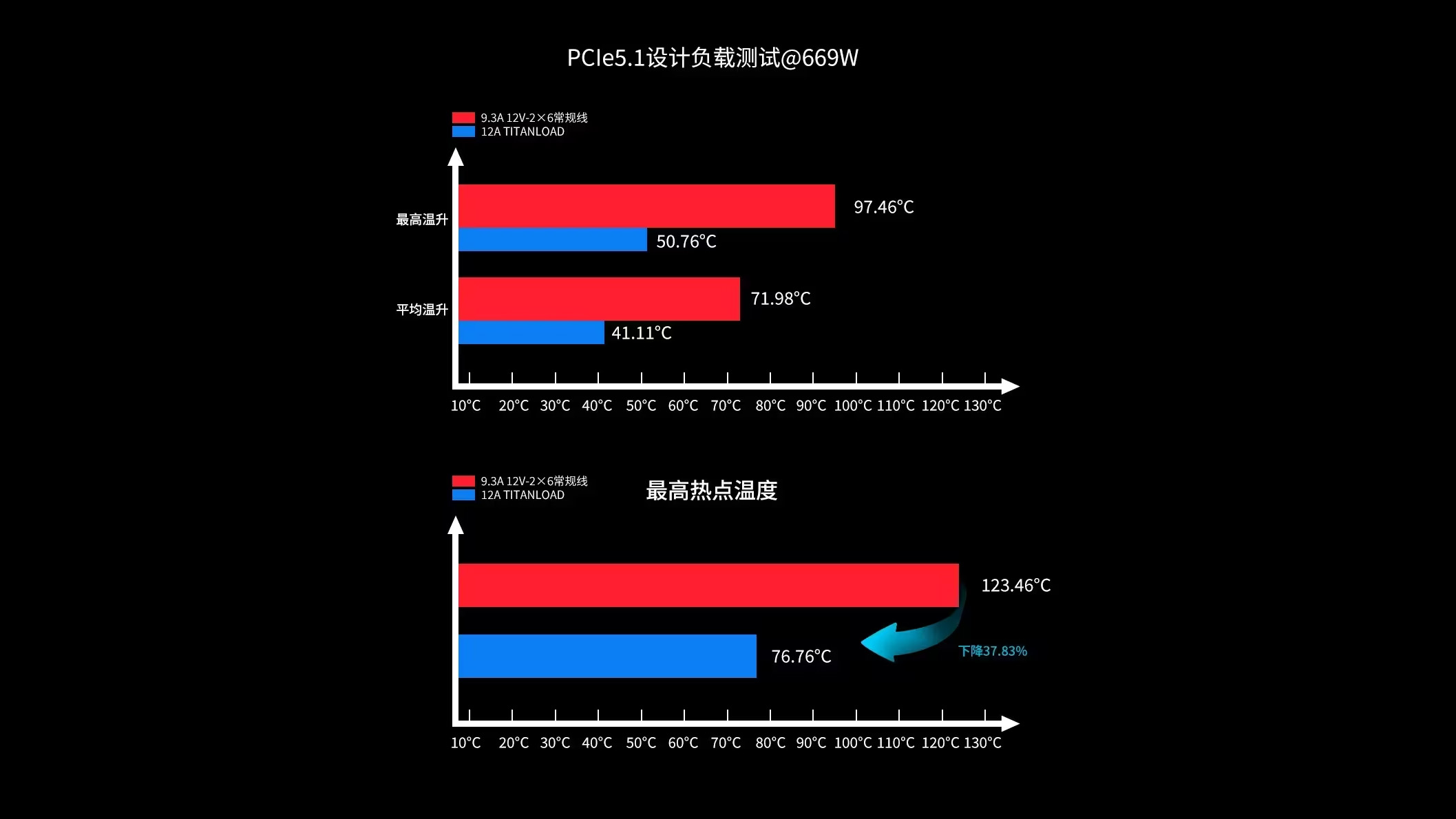

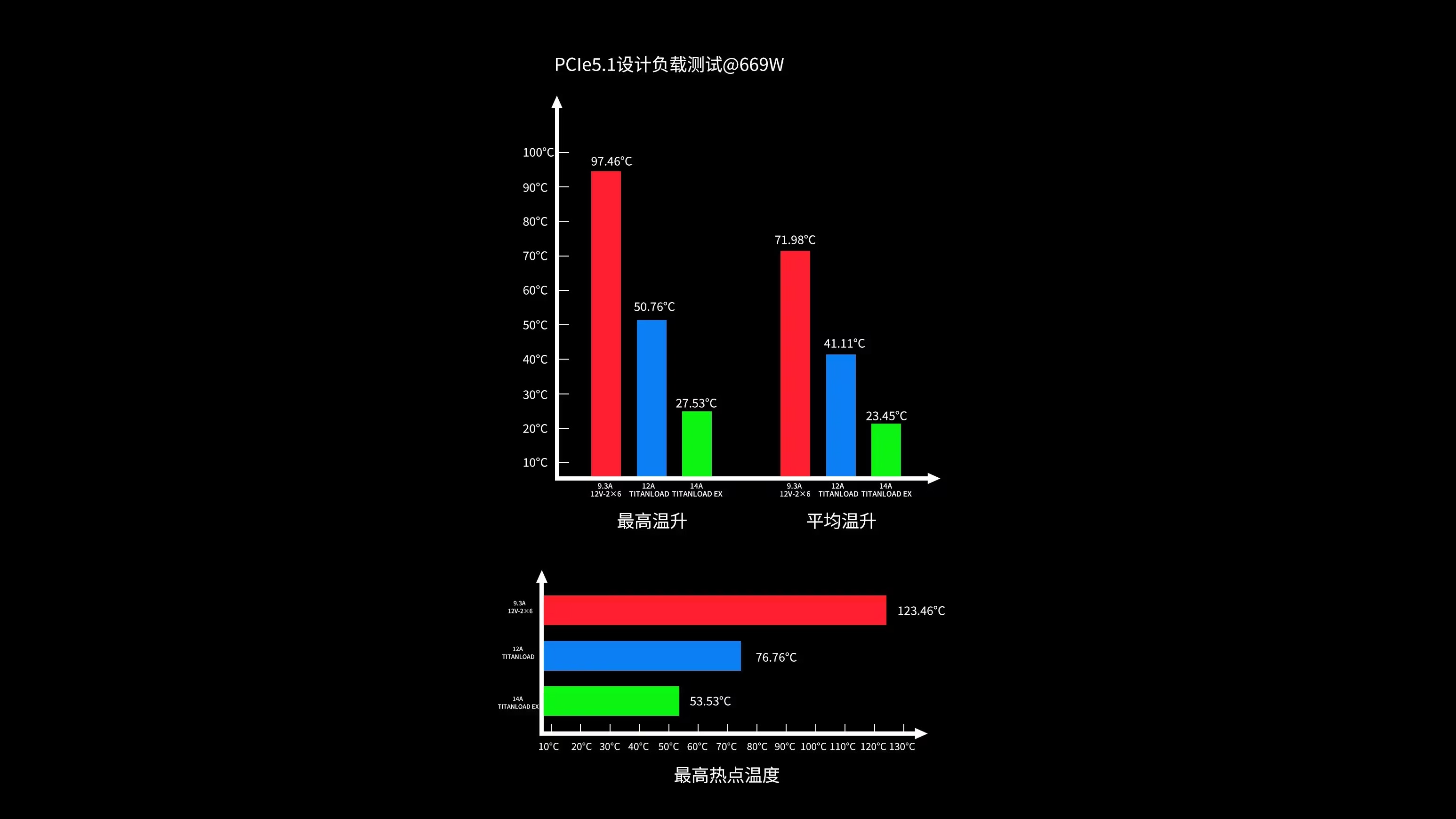

Segotep performed a standard test under ambient conditions at a temperature of 26 degrees Celsius, without the use of air cooling, with a load of 669W at 9.3A. The company subsequently increased the load to 864W at 12A for an extreme test, and further to 1,080W at 15A for a suicide test.

The basic Titanload cable produced a 43% reduction in average temperature and a 48% reduction in peak temperature compared to a standard 12V-2x6 cable. Additionally, the hot spot was 38% cooler.

Meanwhile, the results for the Titanload EX cable, designed for overclockers, were even more remarkable. The average and peak temperatures decreased by 67% and 72%, respectively, and the hot spot dropped by 53%.

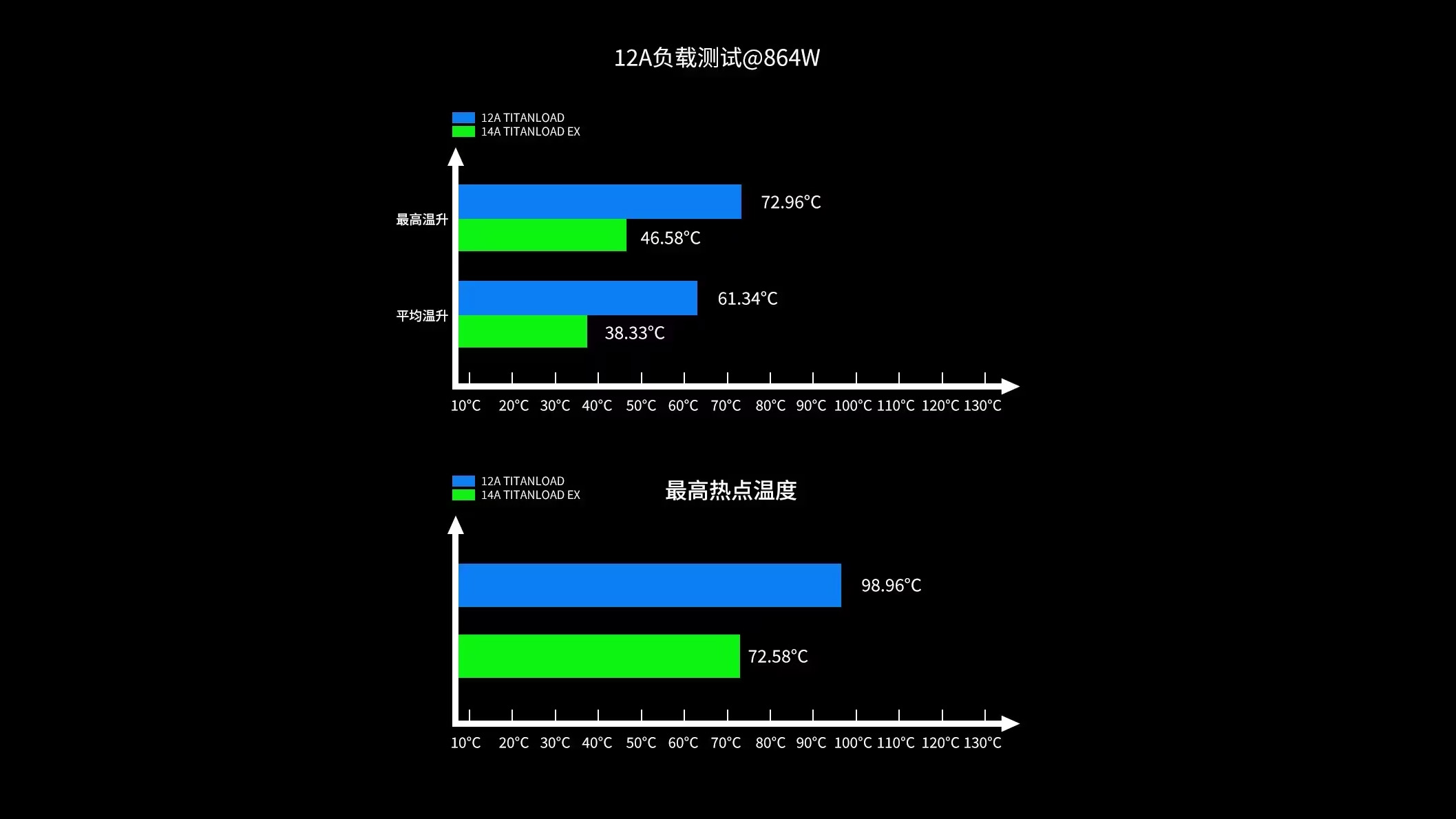

Logically, no results were provided for a standard 12V-2x6 power connector during the extreme test, as the power load significantly exceeds the specified limits. Although a direct comparison was not feasible, Segotep did compare the Titanload and the Titanload EX, with the latter clearly having the advantage due to its pins possessing higher current ratings.

The Titanload cable demonstrated temperatures below 75 degrees Celsius, whereas the Titanload EX cable's temperatures remained significantly lower, well below 50 degrees Celsius. The observed temperature difference approximates up to 38% lower temperatures for the Titanload EX. Regarding the hot spot, the Titanload cable nearly reached 100 degrees Celsius, while the Titanload EX cable remained below 75 degrees Celsius, representing an approximate 27% reduction in temperature.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

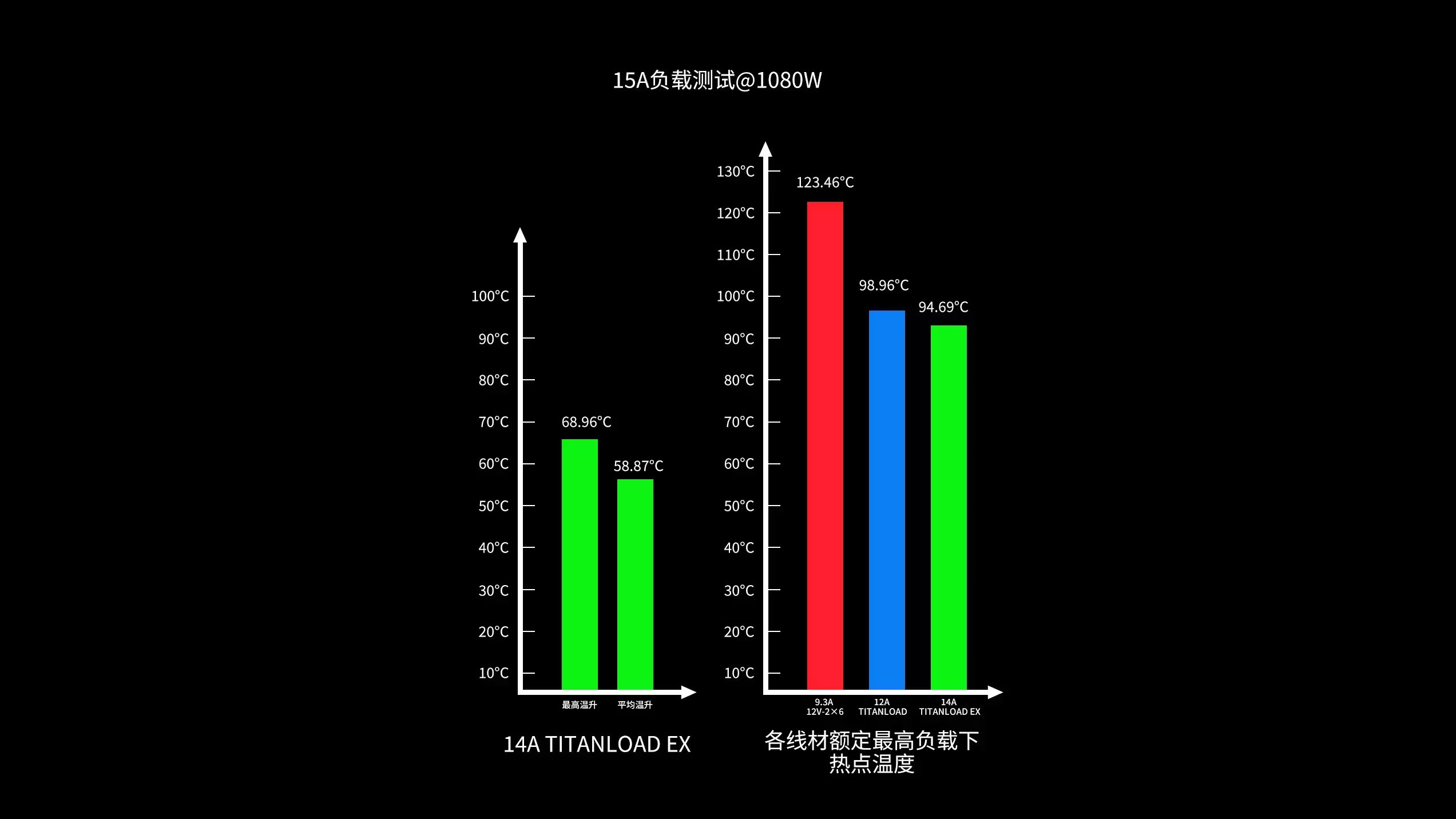

Under the suicide test, the Titanload EX cable maintained hotspot temperatures below 95 degrees Celsius, whereas the standard 12V-2x6 cable surpassed 120 degrees Celsius. Notably, there was only a 5% difference between the Titanload cables.

Citing Arrhenius' equation, which states that the failure rate doubles for every 10 degrees Celsius increase in temperature, the Titanload cable has a thermal failure rate of 6.5%, and the Titanload EX cable, with 1.2%, is under a standard load of 669W, that of the 12V-2x6 cable.

Segotep will incorporate the Titanload cables with the company's forthcoming Titanload power supplies intended for Nvidia's GeForce RTX 50 (codenamed Blackwell) series and subsequent products. Nevertheless, the company has not yet confirmed whether the Titanload cables will be sold separately.

Segotep is not the first brand to try to seek a solution to prevent meltdowns of the 12VHPWR and 12V-2x6 connectors. Numerous companies have endeavored to address this issue. Superficial efforts include coloring the connector to help users ensure correct insertion, while more sophisticated solutions use devices that monitor power usage or provide load balancing. Additionally, the DIY community has proposed innovative workarounds. It remains to be seen whether Segotep's brute-force attempt will have any greater success in preventing failures.

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

Zhiye Liu is a news editor, memory reviewer, and SSD tester at Tom’s Hardware. Although he loves everything that’s hardware, he has a soft spot for CPUs, GPUs, and RAM.

-

TechieTwo Assuming equal metal resistance, it all boils down to pin contact area. Even solid copper pins with minimal contact area can overheat. As the contacts heat up the electrical resistance increases causing a snowball effect that results in failure. Obviously for 9+ amps the pin contact area should have been increased because you rarely get ideal terminal contact in these push fit connectors.Reply -

nimbulan I'm really curious how they're accomplishing this. There's not exactly a lot of space to work with in these tiny connectors to fit more robust terminals inside.Reply -

King_V I'm curious at to whether the rest of the Segotep PSU is up to the task. Unless they've changed in the past couple of years, weren't they generally considered a dumpster-fire level of quality?Reply -

thisisaname Reply

Just what I was thinking it does not matter how solid the pins are if the contact between socket and pins is poor.TechieTwo said:Assuming equal metal resistance, it all boils down to pin contact area. Even solid copper pins with minimal contact area can overheat. As the contacts heat up the electrical resistance increases causing a snowball effect that results in failure. Obviously for 9+ amps the pin contact area should have been increased because you rarely get ideal terminal contact in these push fit connectors. -

edzieba Like with every random out-of-spec bodge attempting to 'fix' 12V 2x6, expect this to cause more problems than it solves (e.g. the Cablemod adapters).Reply -

razor512 One issue of 12VHPWR compared to older standards is ones like the PCIe 6+2/8 pin power connector, is that the connector of the older standard has a much more robust mating surface that well exceeds how much movement is possible within the cable housing, and the mating surface effectively has far more current handling capabilities than the wire itself.Reply

No cable has perfect manufacturing or perfect tolerances, for example, the image below is of the 8 pin connector tat came with my power supply, the image on the left is from a light amount of force pulling on the connector housing, this causes the contacts inside to become more recessed. The image on the right is with a light amount of force pushing onto housing, causing the contacts to be closer to the end of the connector.

With the design of the connector, both positions result is the contact patch still making full contact, thus essentially compensating for poor manufacturing tolerances.

12VHPWR doesn't do that, and thus you can end up with a connector where the housing is fully seated, but the contacts are still not making 100% contact. Basically any stress that causes the contacts to back out slightly or the rear part of the stamped sheet that contains the contacts that mate with the pins to angle slightly, will result in reduced contact. Any angling will mean one side loses contact.

Ideally it is best to significantly overbuild the connector, e.g., for EVs the connector can handle far more amperage than what the wire is rated for, Even for standard NEMA outlets, the the contacts are rated for significantly more amperage than the gauge of the wire, and the contact surface utilizes a plug that is effectively twice the length needed for full contact in the socket, thus even if a cable slips out a little, it won't start a fire in your outlet while pulling the amperage rated in the electrical code.

https://i.imgur.com/4kg8eJB.jpeg

https://i.imgur.com/8bVyLOq.jpeg -

Zaranthos Brute force? It's just common sense that using a more sturdy connector, higher quality material, and something that can carry more current without heating up would provide both a more solid connection and reduced heat.Reply

You younger people would marvel at the supposed lack of engineering from overbuilt old American made products that people still pull out of landfills to find they still function and last forever because they were built to last not built to maximize profit and minimize materials used. Too much crap these days is built to last only as long as the product warranty is good so you'll buy the extended warranty. There was a time when stuff was thrown away not because it quit working but because it went out of style.