PSU Repair: A Case Study

When your PSU won't start, most enthusiasts don't go beyond a paperclip or multimeter check. Today, we'll do a comprehensive repair of Antec's old SL300.

Words Of Caution

When servicing electronics, do not presume you know anything before double-checking everything, and do not assume the manufacturer knew what it was doing either. Otherwise, you may get surprises. And surprises when you are poking around live surfaces at 100V or more with a significant energy source or reservoir attached are usually unpleasant, potentially scary, potentially costly, potentially painful and potentially worse. Lots of potential.

Another thing to keep in mind while working on circuits that carry significant voltages: even if the occasional zap might not cause any actual harm, over-reacting to the zap may cause worse injuries.

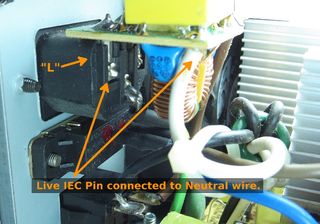

Can you guess what sort of mistake lead to this? The power supply was supposedly turned off when I picked it up to put elsewhere (while still plugged in), the chassis wall bowed in and shorted against the heat-sink. No, the mistake was not that the switch was actually on. I double-checked before picking it up and checked again after the fact; it was still off.

The mistake was assuming that the power supply's IEC socket had been wired properly. Somehow, Antec's manufacturer (Channelwell in this case) got the live and neutral wires backwards, which means that in the “off” position, the neutral line gets opened and everything on the primary side becomes live instead of neutral. That includes the primary-side heat sink, which is tied to the low-side input cap. With the wiring issue, live got shorted to ground through the rectifier bridge leg tied to neutral and heat sink. At least now I know my ground is good, otherwise it would have been a shocking experience. On the downside, this busted one diode inside the rectifier bridge, along with the fuse.

If some of you were wondering why there are separate neutral and ground wires in electrical installations when the two get bonded together at the breaker box anyway, the above would be one justification. Ground is practically always ground when it's present. Live and neutral get wired incorrectly far more frequently.

Hacking Forward

Since I am only using this supply on 120V, only one half of the bridge gets used. Thankfully, the only shorted diode from that mishap was on the normally-unused half of the bridge, so I worked around it by simply hacking off the affected AC-side leg. For the fuse, I went cheap and dirty with a thin jumper wire. This power supply is not going to be used unattended until I fix it, so I am not going to bother with being prim and proper until I have a confirmed fix I am satisfied with.

For safety reasons, I also took a few minutes to fix the incorrectly-wired IEC socket so that “off” really means no power anywhere beyond the switch. Inserting a thick zip-tie between the heat sinks and wall will prevent future shorts while the unit is open-frame.

Current page: Words Of Caution

Prev Page Preliminary Testing: PS_ON# Behavior Next Page PCB AnalysisStay on the Cutting Edge

Join the experts who read Tom's Hardware for the inside track on enthusiast PC tech news — and have for over 25 years. We'll send breaking news and in-depth reviews of CPUs, GPUs, AI, maker hardware and more straight to your inbox.

-

Nuckles_56 An interesting read, it was interesting following the process you used to troubleshoot the problemReply -

Crashman I used to do this for a living :)Reply

Don't tell my boss, I've managed to convince him that I'm only an expert at running benchmarks and writing about the results :) -

epsiloneri Disclaimers won't help. The people who will likely hurt themselves trying this are the same who lack the reading comprehension and self awareness to understand those disclaimers are directed at them. I admire you courage in publishing this.Reply

-

beetlejuicegr the truth is the paper clip and multimeter is all i can go in to psus. after all i haven't studied electricity or circuits or whatever.Reply

However i do hate to throw stuff earlier than it should, like you. -

C12Friedman I like this article and I fully agree with the conclusion. I've repaired a few PSU's but, for the most part I scavenge them anymore since I can't put them in a new system (nor would I want to) IMO they aren't really worth anything other than for on a test bench.Reply -

Mr A Daniel, I know next to nothing about electronics, and yet I could not stop reading this article. Fascinating! Thanks very much!Reply -

Urzu1000 This was a great article! It was informative, as well as interesting. Personally, I've only had one PSU fail on me so far. My brother-in-law's self-built computer had a really low-end Thermaltake PSU. 800W Bronze, and oh man, did that thing go out in a blaze of glory. Very loud popping, and smoke, and funny smells. When I ripped it out of the computer, there were burns inside the case. Miraculously, the other components remained unharmed, so I slapped in a new PSU (750W Gold Seasonic) and fired it up.Reply

Still working good, but I get black soot on my hands every time I open up that case. It's a black case, so it's hard to clean it off properly. -

Interesting article. I would have simply replaced the entire unit. You saw how to fix the failure, but how many units were damaged that you didn't see? A ticking time bomb that will eventually send some spike to your much more valuable hardware than a 10 year old PSU. Wasteful, yes. I get it. I don't like to waste either. And if it's on marginal hardware, fine. But on primary systems I'm not willing to take the risk. I'd rather throw away a 200$ part that has a 0.05$ repair solution, than risk frying 800$+ hardware.Reply

-

kalmquist "Antec's manufacturer (Channelwell in this case) got the live and neutral wires backwards, which means that in the “off” position, the neutral line gets opened and everything on the primary side becomes live instead of neutral."Reply

That's really bad--I doubt it is even legal to sell a power supply wired like that. I've never bought a CWT (Channelwell) power supply, and based on this I wouldn't buy one, except perhaps for a high end model where you might gamble that the company would exercise a bit more care.