Tom's Hardware Verdict

The Cooler Master Elite NEX W600 offers passable performance for entry-level builds but suffers from outdated internal topology. While acceptable for basic repairs, it lacks the stability and efficiency required for modern gaming or high-performance PCs.

Pros

- +

Affordable retail price

- +

Compact 140mm dimensions

- +

3 year warranty

- +

Good low-load efficiency

- +

Passable ripple suppression

- +

Solid assembly quality

- +

Low idle noise

Cons

- -

Outdated design

- -

Group regulation issues

- -

Low efficiency

- -

Loud at high loads

Why you can trust Tom's Hardware

Cooler Master Technology Inc., established in 1992 and headquartered in New Taipei, Taiwan, is a renowned manufacturer of PC computer hardware with decades of experience under its belt. As the name suggests, the company began as a PC cooling solution manufacturer but soon began diversifying towards anything PC power and cooling related, as well as PC-related furniture and peripherals. Alongside its retail business, Cooler Master is also an original equipment manufacturer of cooling devices for other manufacturers.

In this review, we examine the Elite NEX W600, an entry-level 600W power supply that represents the absolute bottom tier of Cooler Master's PSU portfolio. This unit targets the budget-conscious consumer with its 80Plus White certification and three-year warranty. However, beneath its basic exterior lies a design philosophy that feels lifted from a previous decade. The dual-forward topology with group regulation is a relic from an era when PC power requirements were fundamentally different, and its continued presence in new products raises serious questions about value and longevity. Unfortunately, the Elite NEX W600 fell short and did not get a spot in our best power supplies list. While the unit carries an affordable price point, its technical compromises are substantial enough to warrant careful consideration before purchase.

Specifications and Design

RAIL | +3.3V | +5V | +12V | +5Vsb | -12V |

MAX OUTPUT | 17A | 19A | 46A | 2.5A | 0.3A |

| Row 2 - Cell 0 | 110W | 110W | 552W | 12.5W | 3.6W |

TOTAL | 600W | Row 3 - Cell 2 | Row 3 - Cell 3 | Row 3 - Cell 4 | Row 3 - Cell 5 |

AC INPUT | 200 - 240 VAC, 50 Hz | Row 4 - Cell 2 | Row 4 - Cell 3 | Row 4 - Cell 4 | Row 4 - Cell 5 |

MSRP | $60 | Row 5 - Cell 2 | Row 5 - Cell 3 | Row 5 - Cell 4 | Row 5 - Cell 5 |

In the Box

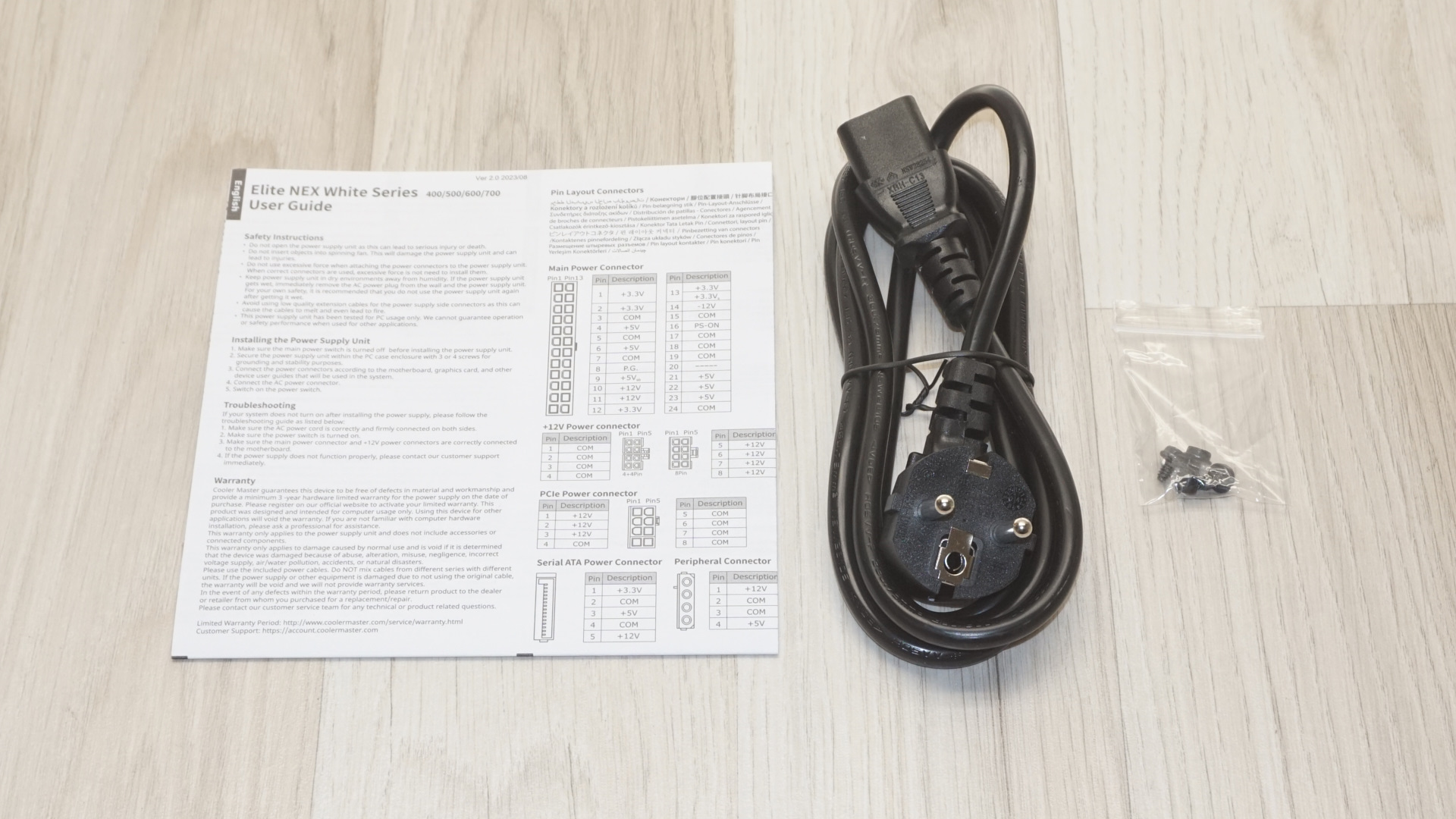

The Cooler Master Elite NEX W600 arrives in a durable cardboard box featuring the black and purple aesthetic that Cooler Master frequently uses. The front prominently displays an image of the unit itself. Internal protection is minimal, consisting only of basic cardboard inserts without any protective pouch or foam padding.

The bundle reflects the unit's budget positioning. Inside you will find only the AC power cable and mounting screws. There are no cable ties, straps, or accessories of any kind. This spartan approach is typical for the lowest price segment.

All cables are hardwired directly to the unit, eliminating any modular flexibility. The cables feature an all-black color scheme with black connectors and wires. Only the ATX 24-pin cable receives an additional black sleeving. The remaining cables are exposed, with larger bundles held together by basic cable ties. The unit is ATX 2.42 compliant, meaning there is no 12V-2x6 connector for modern graphics cards. This immediately limits its applicability in contemporary builds requiring ATX 3.x compatibility.

Connector type | Hardwired | Modular |

|---|---|---|

ATX 24 Pin | 1 | - |

EPS 4+4 Pin | 1 | - |

EPS 8 Pin | - | - |

PCI-E 5.0 | - | - |

PCI-E 8 Pin | 2 | - |

SATA | 5 | - |

Molex | 3 | - |

Floppy | - | - |

External Appearance

Cooler Master has applied a matte black chassis paint to the Elite NEX W600, creating a clean and professional appearance. The finish quality is acceptable, though it shows a tendency to scratch more easily than premium powder coating. The design remains thoroughly conventional, adhering to the standard rectangular PSU form factor without any aesthetic embellishments beyond function.

A decorative sticker adorns the left side of the chassis, while the electrical specifications and certification sticker occupies the right side. The top surface remains completely plain. The unit measures exactly 140 mm in length, conforming precisely to ATX standards. This ensures compatibility with any ATX-compliant case without requiring clearance verification.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The front panel hosts only the standard AC cable receptacle and on/off switch. The rear side is unadorned, as all cables are hardwired and enter the chassis internally. The fan finger guard integrates directly into the chassis with a typical circular cutout pattern.

Internal Design

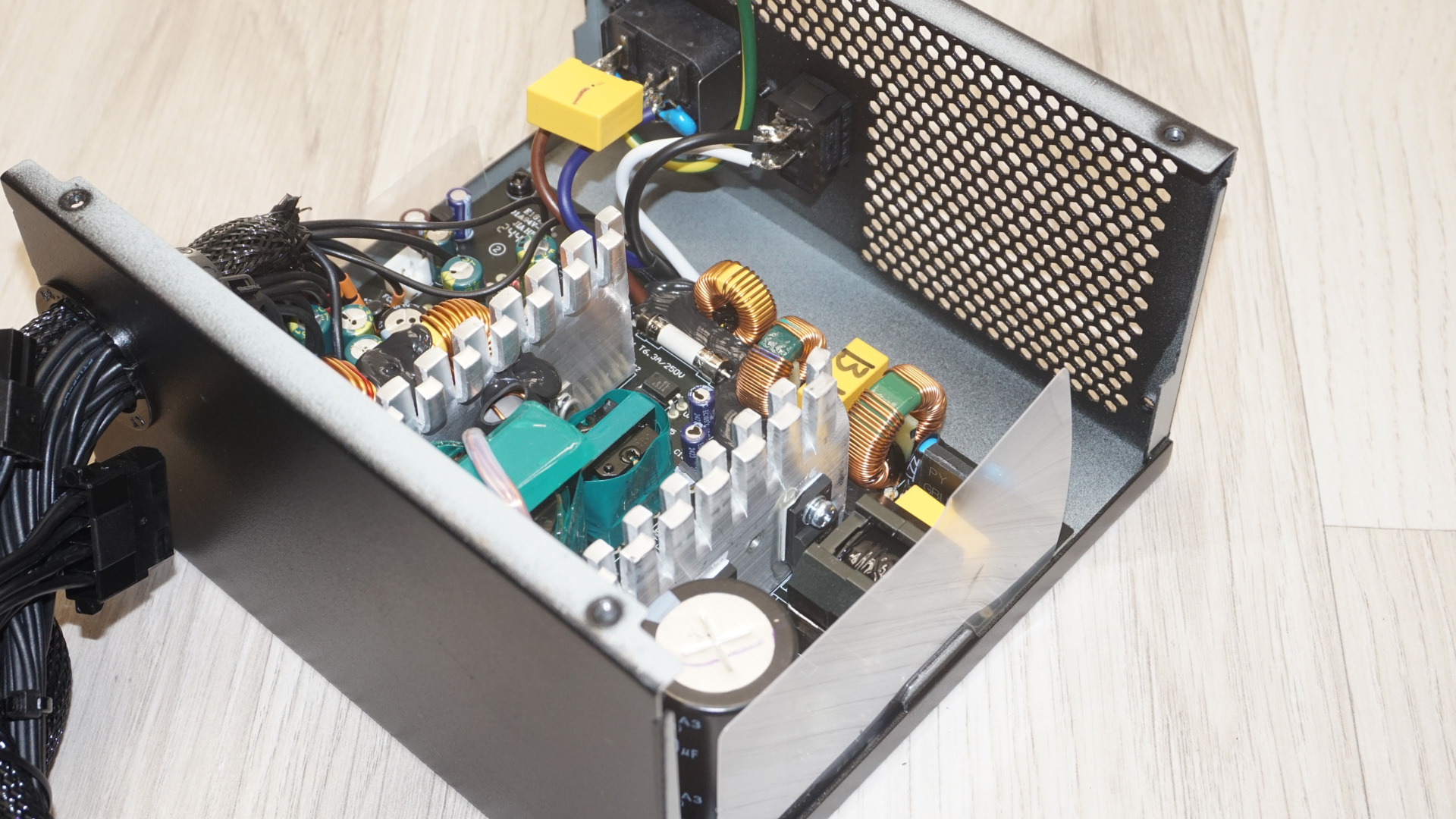

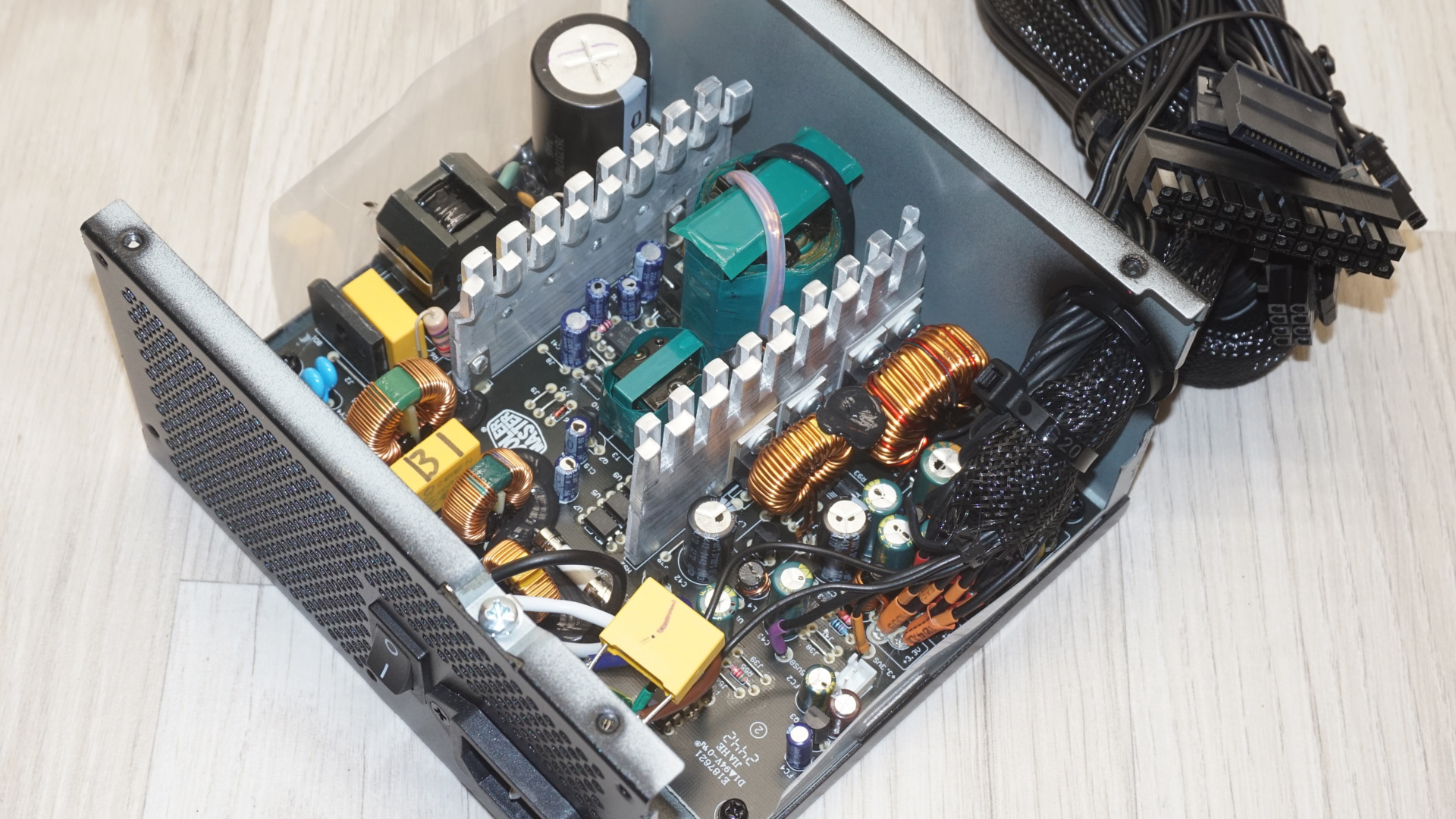

Cooling duties fall to a 120 mm fan carrying the part number DF1202512SEHN. This is a common sleeve bearing design frequently sold by Cooler Master, though the actual OEM is likely Martech. Sleeve bearing fans offer reasonable quietness and reliability under normal conditions but represent the least durable fan type in modern PSU applications. These engines are particularly vulnerable to shortened lifespans when exposed to sustained high temperatures. While no official datasheet exists for this specific model, our measurements indicate a maximum speed of approximately 2200 RPM.

The OEM responsible for this unit is HEC, also known as Compucase, a Taiwan-based manufacturer established in 1979. HEC is one of the world's leading manufacturers of computer cases and switching power supplies, with manufacturing facilities in both Taiwan and mainland China. The company operates as both an OEM supplier to major electronics brands and maintains its own retail product lines.

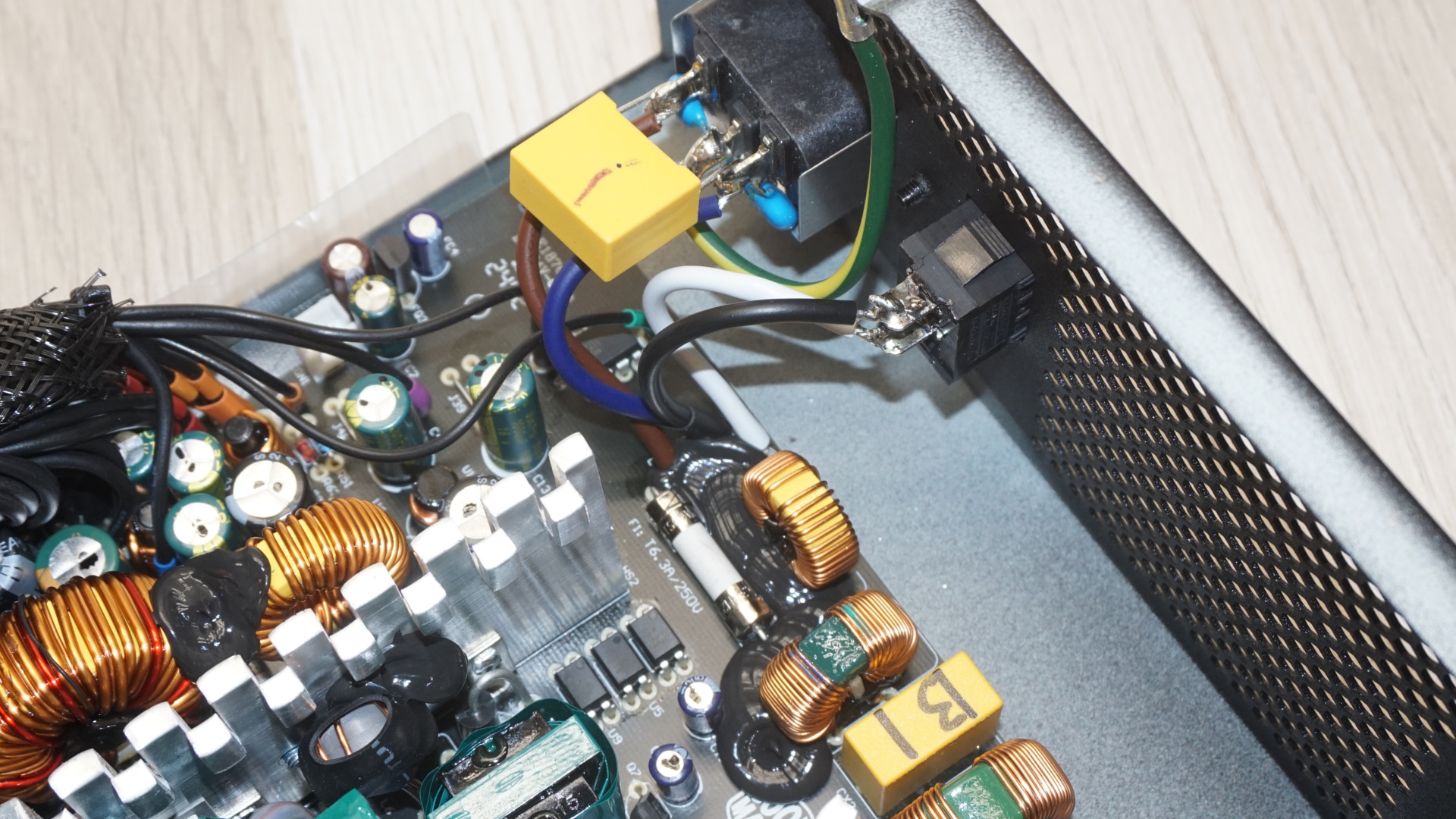

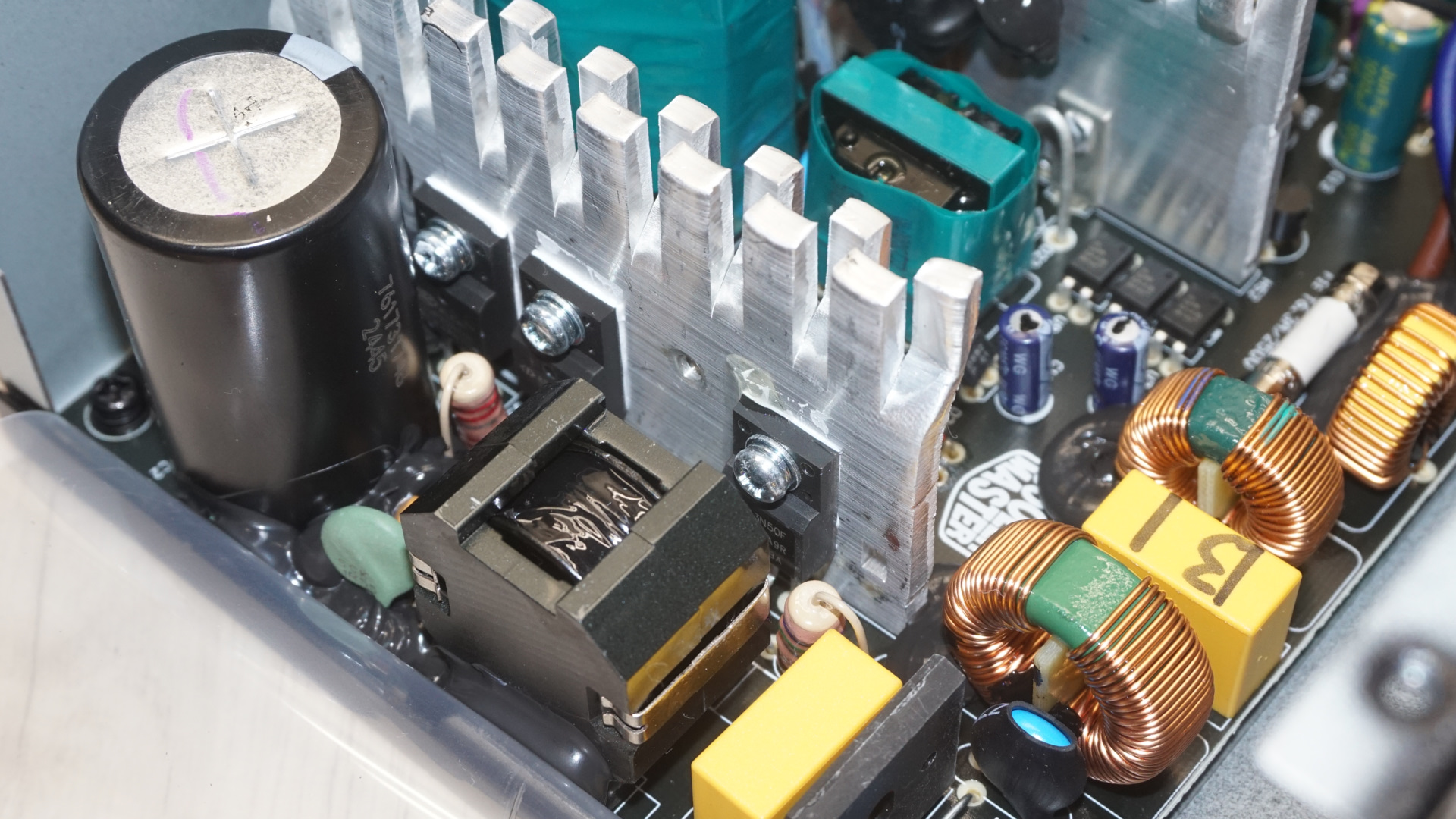

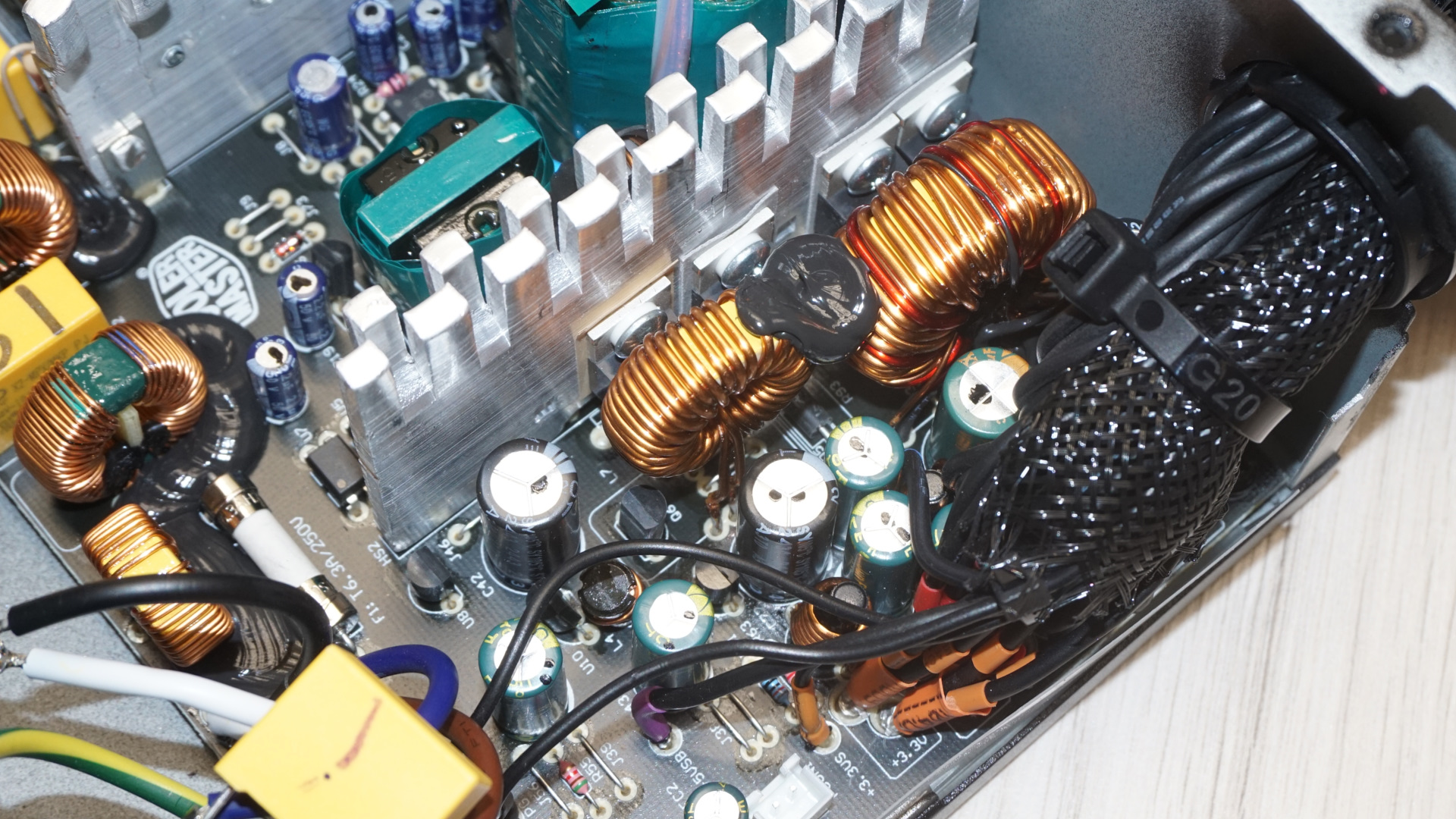

The input filtering stage provides adequate suppression with four Y capacitors, two X capacitors, and two filtering inductors. Unusually for a contemporary design, a glass fuse sits in the circuit path. A single rectifying bridge follows the filtration stage, notably without any heatsink to assist thermal dissipation.

The APFC circuitry utilizes two CS13N50F MOSFETs paired with a diode for active components. One small encased inductor and a single Teapo 330 μF capacitor handle the passive duties. The primary inversion stage employs two SVF20N50F MOSFETs configured in a half-bridge topology. These share a heatsink with the APFC components. While the heatsinks appear basic, they should prove adequate for a 600W power output, though thermal margins are not generous.

The secondary side reveals the most problematic aspect of this design: a dual-forward topology with group regulation. This architecture is severely outdated by modern standards. The topology utilizes a shared toroidal inductor for the 12V and 5V rails, intrinsically linking their regulation. This creates inevitable voltage stability issues under unbalanced cross-loads, which is precisely the loading pattern modern systems exhibit. Furthermore, the design employs Schottky barrier diodes instead of synchronous rectification with MOSFETs, directly resulting in lower efficiency and higher thermal losses.

Secondary side capacitors come primarily from Teapo, with a few Jamicon units appearing after the primary side. Neither manufacturer ranks among the most prestigious names in the capacitor industry, but both are established and reliable within the budget segment. This represents better component selection than typically expected at this price point.

Cold Test Results

Cold Test Results (25°C Ambient)

For the testing of PSUs, we are using high precision electronic loads with a maximum power draw of 2700 Watts, a Rigol DS5042M 40 MHz oscilloscope, an Extech 380803 power analyzer, two high precision UNI-T UT-325 digital thermometers, an Extech HD600 SPL meter, a self-designed hotbox and various other bits and parts.

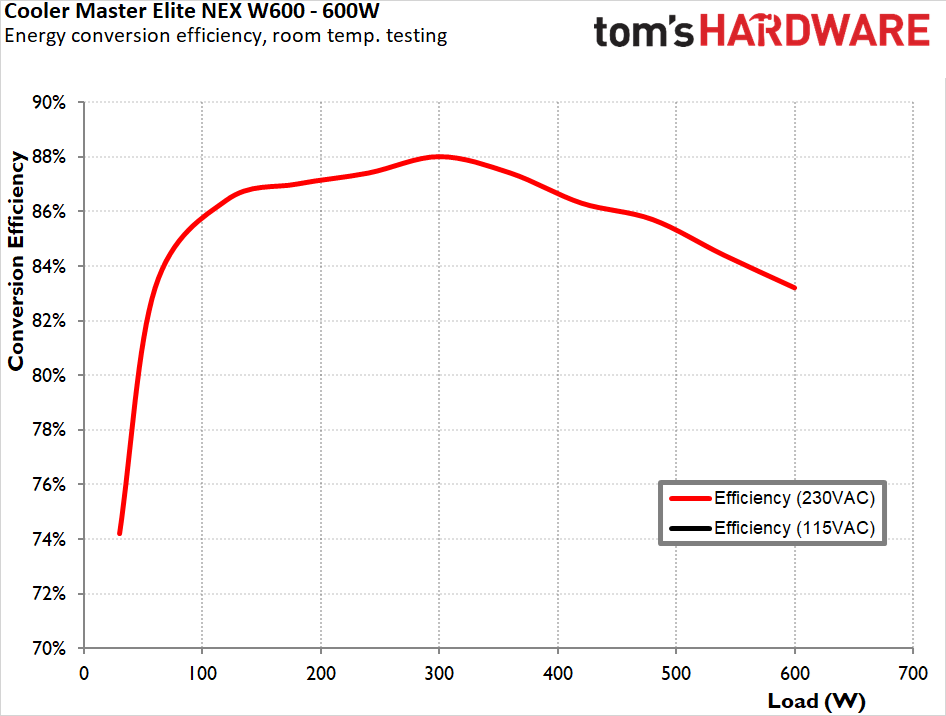

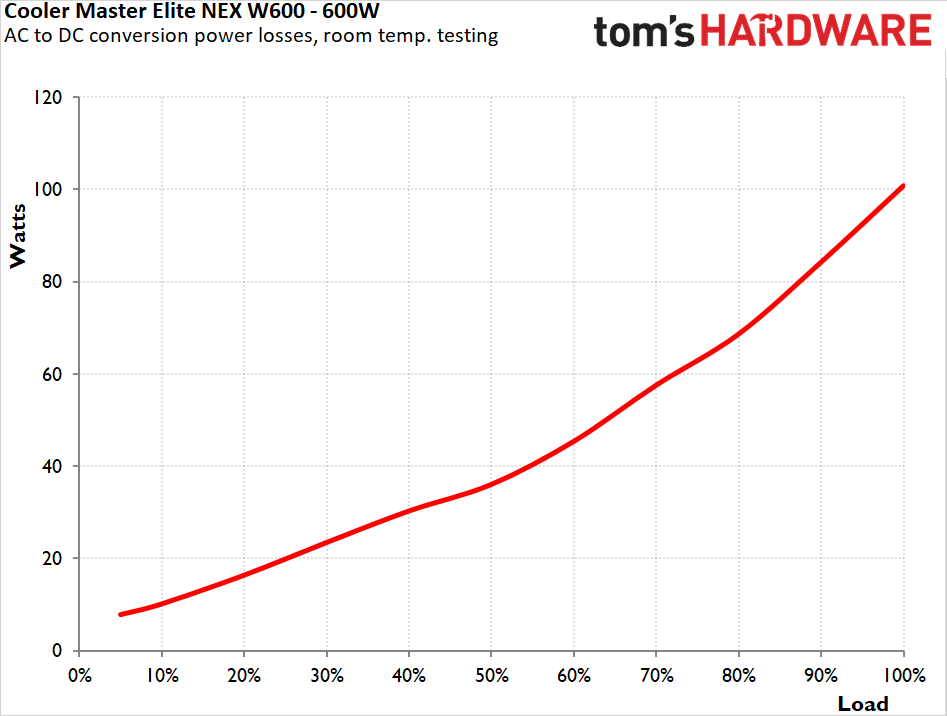

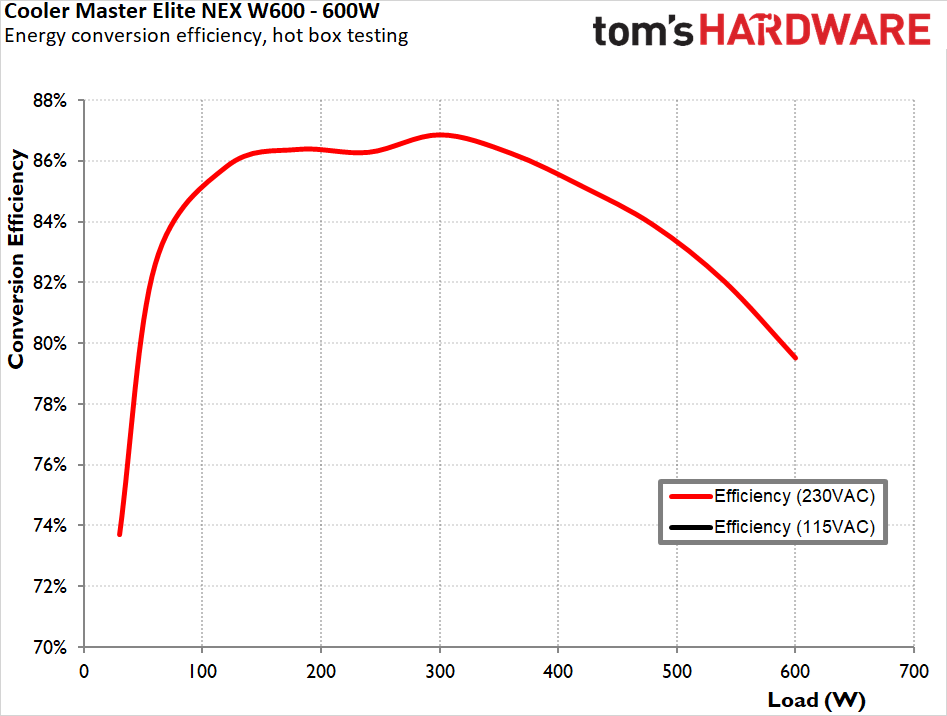

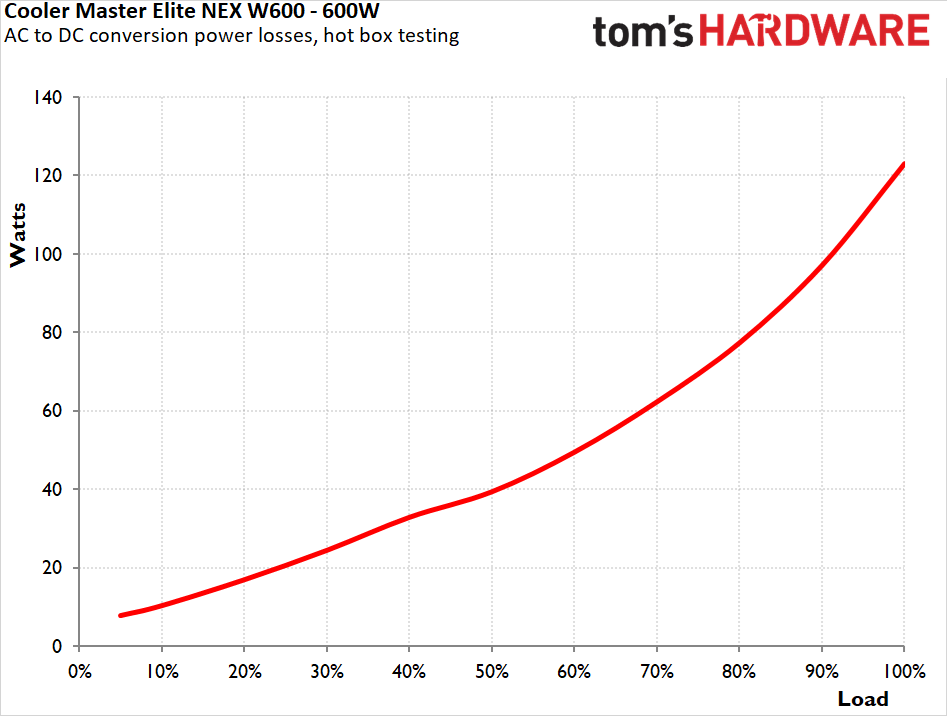

This particular EU model operates exclusively with an input voltage range of 200-240 VAC, limiting our testing to 230 VAC input. Cooler Master offers a wide input variant (100-240 VAC) for global markets. The nominal load range efficiency proves disappointing at 85.9% average. Efficiency peaks at approximately 50% load but drops significantly at both lower and higher loads, creating an unstable efficiency curve. The unit meets the most basic 80Plus certification from CLEAResult (White) at 230 VAC input. It carries no Cybenetics or PPLP.info certifications.

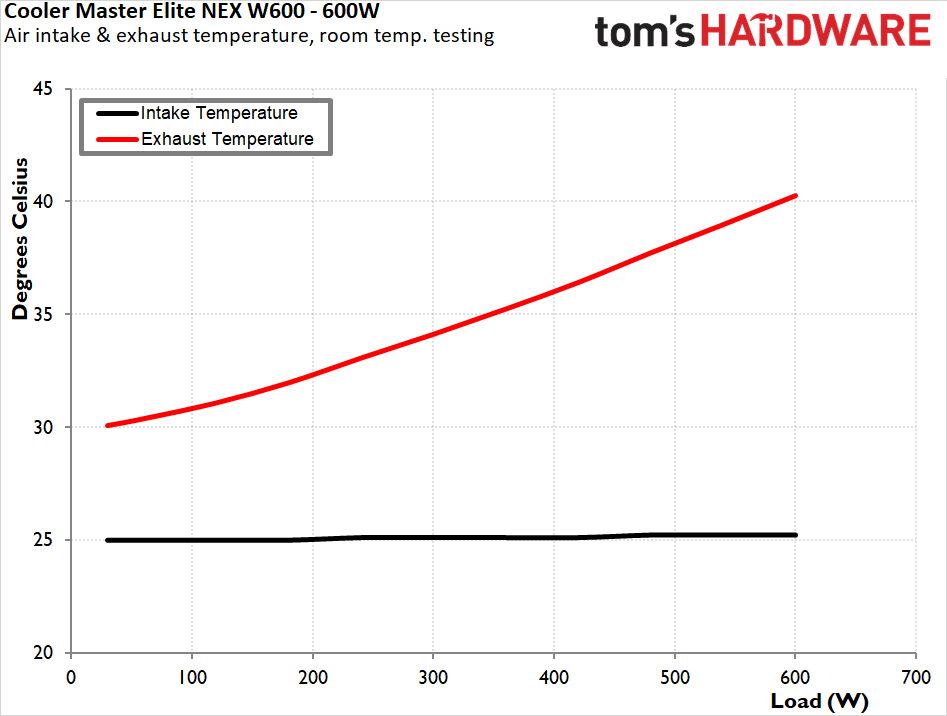

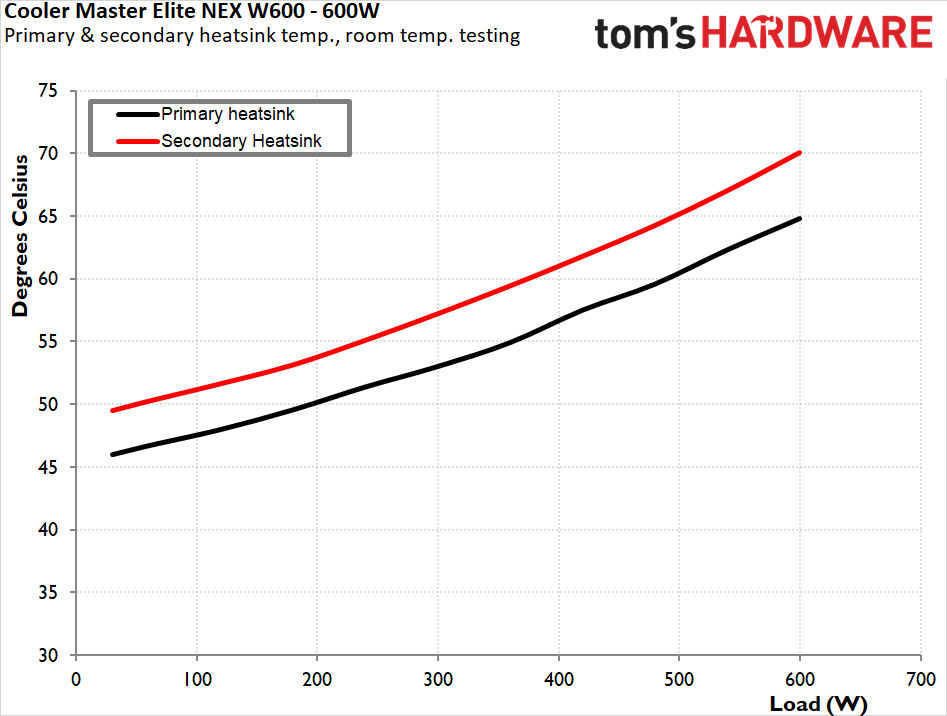

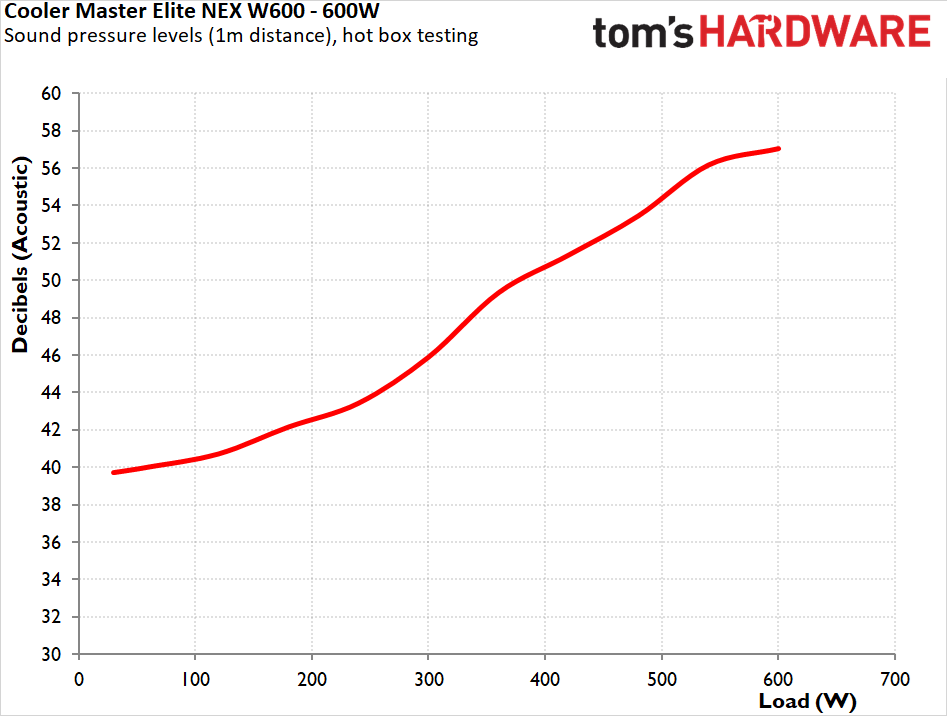

The fan operates continuously across all load ranges. Fan speed increases almost linearly with load but never reaches maximum velocity even at 100% output. Thermal performance remains passable, which is adequate given the unit's substantial thermal losses from poor efficiency.

Hot Test Results

Hot Test Results (~45°C Ambient)

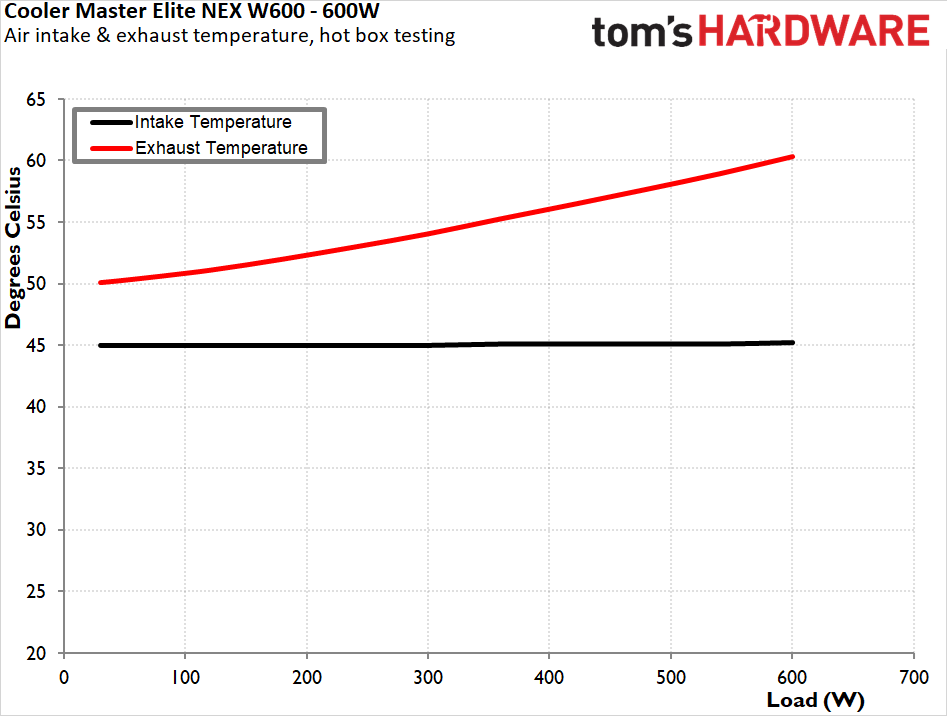

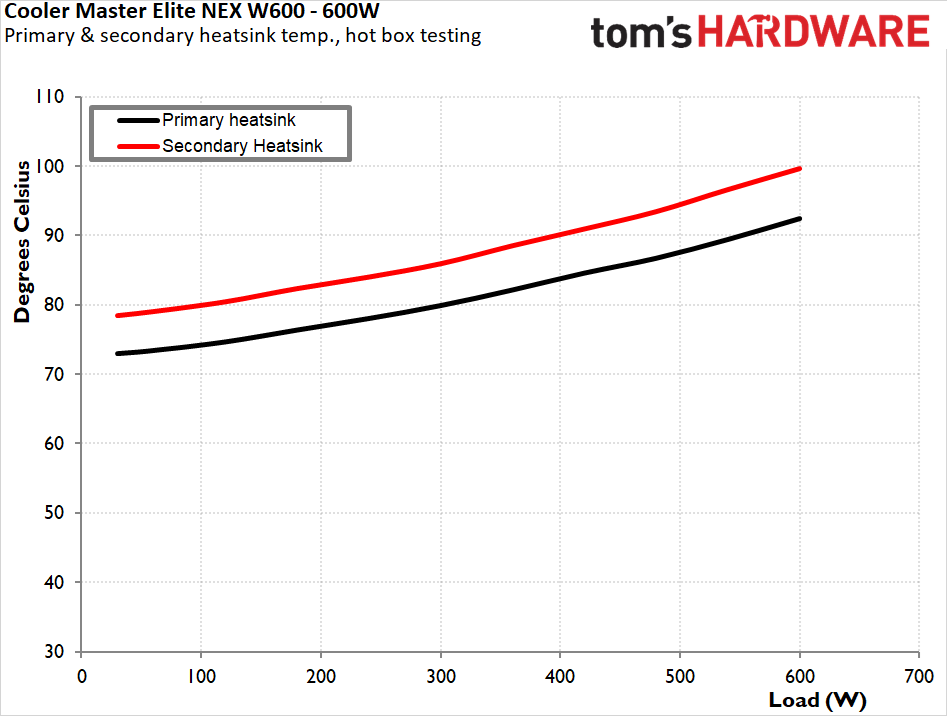

Under elevated ambient temperatures, efficiency degradation reveals concerning patterns. Average nominal load efficiency drops to 84.5% at 230 VAC input, representing expected reduction at low-to-medium loads. However, efficiency collapses sharply when load approaches maximum, suggesting severe thermal stress under adverse operating conditions. The low efficiency translates to more than 120 watts becoming thermal losses at full load, and the unit's modest cooling infrastructure struggles with this burden.

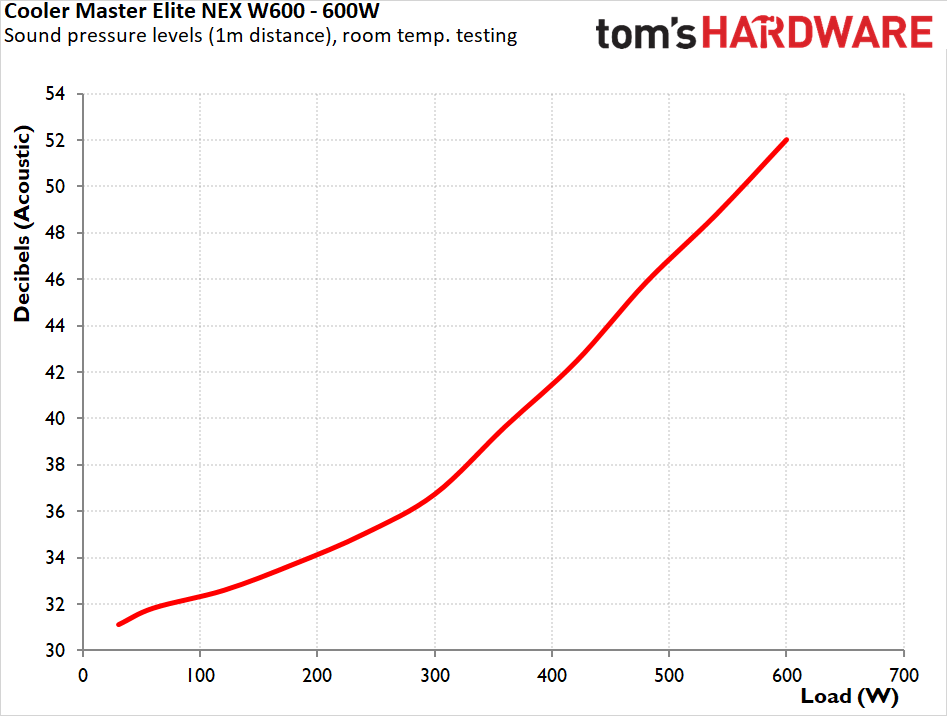

The fan responds aggressively to thermal stress, spinning faster and reaching maximum speed at 100% load despite the relatively modest 600W power output. Internal temperatures climb to very high levels for a unit in this power class, though they remain within operational limits without triggering over-temperature protection. The unit successfully maintains full rated power output with ambient temperatures exceeding 45 degrees Celsius, but the thermal stress is evident. Acoustically, performance is poor. The unit becomes audibly loud even at half-load, and full-load operation produces intrusive noise levels.

PSU Quality and Bottom Line

Power Supply Quality

The Cooler Master Elite NEX W600 delivers acceptable voltage regulation, maintaining deviations below 3% for all voltage rails as the design guide dictates. The 12V rail shows 2.4% regulation, while the 5V and 3.3V rails demonstrate 1.7% and 1.9% respectively. Voltage ripple filtering proves competent for an entry-level product, remaining well below recommended limits with maximum ripple measuring 74 mV on the 12V rail, 36 mV on the 5V rail, and 32 mV on the 3.3V rail. The group regulation architecture creates predictable problems. Heavily loading the 12V line causes significant voltage dip on that rail while simultaneously producing notable overvoltage on the secondary rails. These voltage excursions remain within acceptable ranges that do not trigger protection circuits, but this is not clean power delivery. Modern systems with their heavy 12V emphasis will encounter this cross-regulation issue frequently, potentially impacting component longevity.

During our thorough assessment, we evaluate the essential protection features of every power supply unit we review, including Over Current Protection (OCP), Over Voltage Protection (OVP), Over Power Protection (OPP), and Short Circuit Protection (SCP). All protection mechanisms were activated and functioned correctly during testing.

All mechanisms activated and functioned correctly. The OCP triggers at 117% for the 3.3V rail, 119% for the 5V rail, and 106% for the 12V rail. The OPP threshold sits at 108% under hot conditions. These protection thresholds are appropriately conservative.

Load (Watts) | 123.68 W | Header Cell - Column 2 | 305.86 W | Header Cell - Column 4 | 454.65 W | Header Cell - Column 6 | 603.57 W | Header Cell - Column 8 |

|---|---|---|---|---|---|---|---|---|

Load (Percent) | 20.61% | Row 0 - Cell 2 | 50.98% | Row 0 - Cell 4 | 75.78% | Row 0 - Cell 6 | 100.59% | Row 0 - Cell 8 |

| Row 1 - Cell 0 | Amperes | Volts | Amperes | Volts | Amperes | Volts | Amperes | Volts |

3.3 V | 1.63 | 3.42 | 4.06 | 3.39 | 6.1 | 3.38 | 8.13 | 3.36 |

5 V | 1.82 | 5.13 | 4.54 | 5.1 | 6.81 | 5.07 | 9.08 | 5.05 |

12 V | 8.8 | 12.36 | 21.99 | 12.23 | 32.99 | 12.11 | 43.98 | 12.06 |

Line | Regulation (20% to 100% load) | Voltage Ripple (mV) | Header Cell - Column 3 | Header Cell - Column 4 | Header Cell - Column 5 | Header Cell - Column 6 | Header Cell - Column 7 |

|---|---|---|---|---|---|---|---|

| Row 0 - Cell 0 | Row 0 - Cell 1 | 20% Load | 50% Load | 75% Load | 100% Load | CL1 12V | CL2 3.3V + 5V |

3.3V | 1.9% | 18 | 24 | 28 | 32 | 20 | 34 |

5V | 1.7% | 20 | 26 | 28 | 36 | 20 | 36 |

12V | 2.4% | 24 | 36 | 48 | 74 | 72 | 44 |

Bottom Line

The Cooler Master Elite NEX W600 represents superseded engineering forced into a modern market. HEC brings over four decades of manufacturing experience to this design, and the assembly quality reflects professional workmanship. Component selection from Teapo and Jamicon, while not prestigious, remains adequate for the application. The fundamental issue lies not in execution but in the choice to resurrect a decades-old topology that modern PC requirements have rendered obsolete. The dual-forward topology with group regulation creates inherent voltage stability problems under the 12V-dominant loading patterns that characterize contemporary systems. The use of Schottky diodes instead of synchronous rectification sacrifices efficiency for cost savings, resulting in thermal performance that requires aggressive fan profiles to maintain safe operating temperatures. This manifests as poor acoustics even at moderate loads.

Electrical performance shows the design's limitations clearly. While voltage regulation and ripple suppression meet basic standards, the cross-regulation behavior under unbalanced loads creates power quality issues that modern DC-to-DC regulated designs simply do not exhibit. The efficiency curve is unstable and barely scrapes past the 80Plus White threshold, earning none of the more stringent certifications that indicate modern quality engineering. Acoustically, the unit fails to meet modern expectations. The sleeve bearing fan operates continuously even during light loads. Under sustained operation, it becomes loud and intrusive, making it unsuitable for any system where noise matters.

At its current retail pricing, the Elite NEX W600 offers poor value. The three-year warranty provides some confidence given the design's thermal stress patterns and use of sleeve bearing cooling. This unit might serve as an emergency replacement part for an aging system or a very basic office PC that will never approach its power limits. For any other application, spending marginally more money purchases dramatically superior products with modern topologies, better efficiency, modular cables, and even ATX 3.x compliance.

The Elite NEX W600 exists in a market segment that has largely moved beyond it. While it technically functions, it represents everything modern PSU design has evolved away from. Unless discovered at deep discount pricing for an appropriate legacy application, this unit warrants passing over in favor of more contemporary alternatives.

MORE: Best Power Supplies

MORE: How We Test Power Supplies

MORE: All Power Supply Content

Dr. E. Fylladitakis has been passionate about PCs since the 8088 era, beginning his PC gaming journey with classics like Metal Mutant and Battle Chess. Not long after, he built his first PC, a 486, and has been an enthusiast ever since. In the early 2000’s, he delved deeply into overclocking Duron and Pentium 4 processors, liquid cooling, and phase-change cooling technologies. While he has an extensive and broad engineering education, Dr. Fylladitakis specializes in electrical and energy engineering, with numerous articles published in scientific journals, some contributing to novel cooling technologies and power electronics. He has been a hardware reviewer at AnandTech for nearly a decade. Outside of his professional pursuits, he enjoys immersing himself in a good philosophy book and unwinding through PC games.