Nvidia Shows Off Metal Mold That Will Make Project Shield Casing

How each Project Shield will be made.

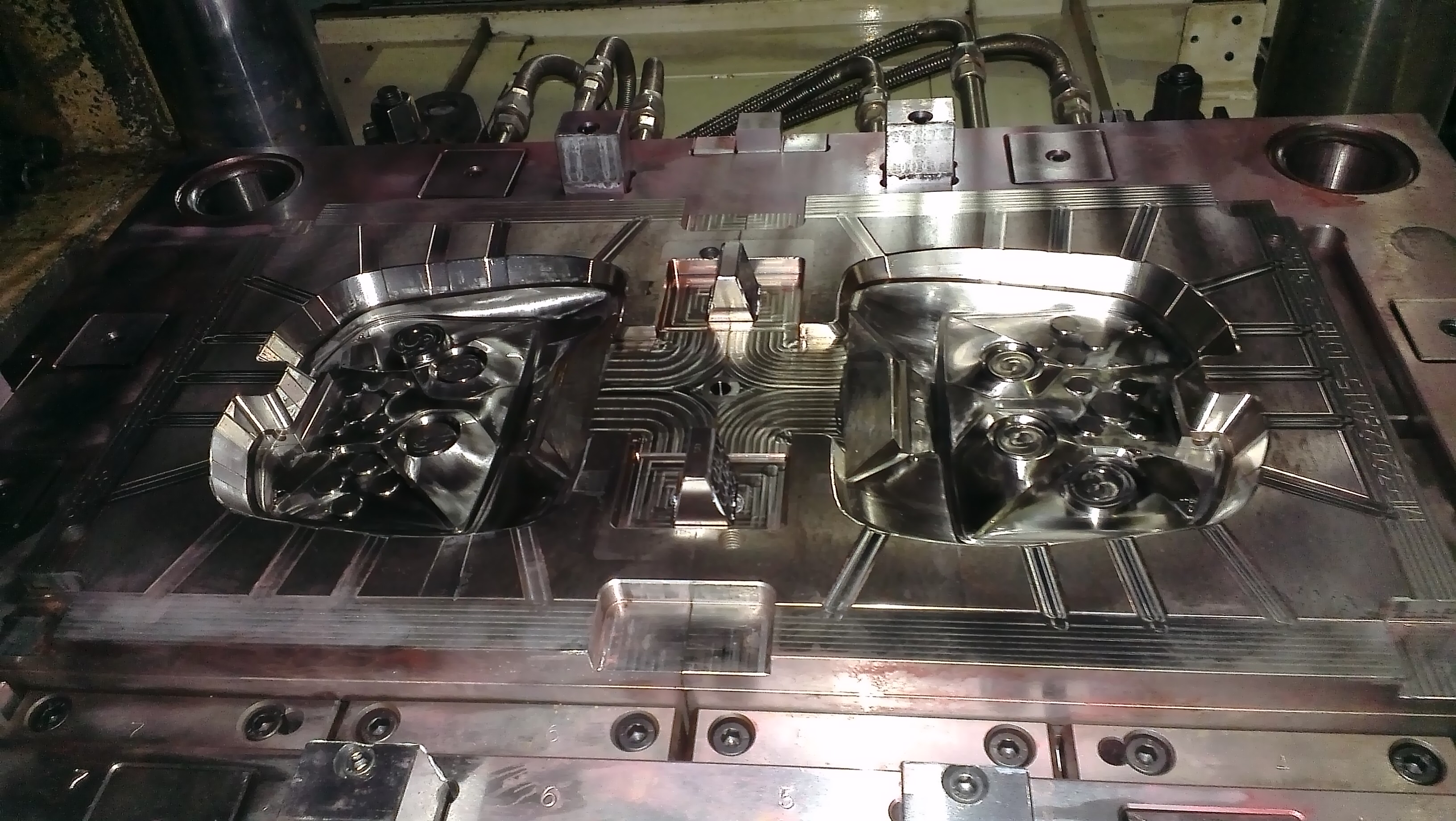

Nvidia's Project Shield is a full expression of the company's desire to jump into the mobile gaming space with its Tegra system-on-chip processors. Tegra 4 will be Nvidia's biggest effort to date, and it'll powering Nvidia's handheld gaming unit. Today the company shared with us the a picture from the manufacturing process:

"The photo you see below shows the production mold that's used to craft the ergonomic casing that houses Project SHIELD's high-powered components: Tegra 4, 5-inch 720p HD retinal touchscreen, Stereo Bass Reflex Speakers, WiFi, accelerometer, gyro, a massive battery, and more.

"To create the casing, we inject a polycarbonate material into the RHCM (Rapid Heat Cycle Molding) tool at 10,800 PSI and 300 degrees Celsius. We use a polycarbonate mixture comprised of 90% Sabic 500ECR-739 PC and 10% glass. This material and injection molding process ensures a sturdy yet lightweight casing that will deliver hours of gaming with no fatigue."

For more, check out our most recent Project Shield hands-on from Nvidia GTC 2013.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

-

kensingtron "720p HD retinal" because retina is copyrighted. Invidia don't empower Apple branding.Reply -

slyu9213 It's not significantly different. D-Pad and Left stick is switched. Seems to be speakers at the top. It's seems like a mix of xbox and n64. They needed to fit the internals in there somehow.Reply -

somebodyspecial Does your xbox controller have a screen attached? Can you run movies on it when out of the home? People say they can run for 10hr without cramps, I can't do that on my xbox360 controller. It can use your PC's gpu...I don't need an xbox now?..etc etc...Reply

I don't understand your question...LOL.

You hate NV how much? :)