The Stout Owl: How I Built the Ultimate Noctua G2 PC

This PC eats opulence for breakfast

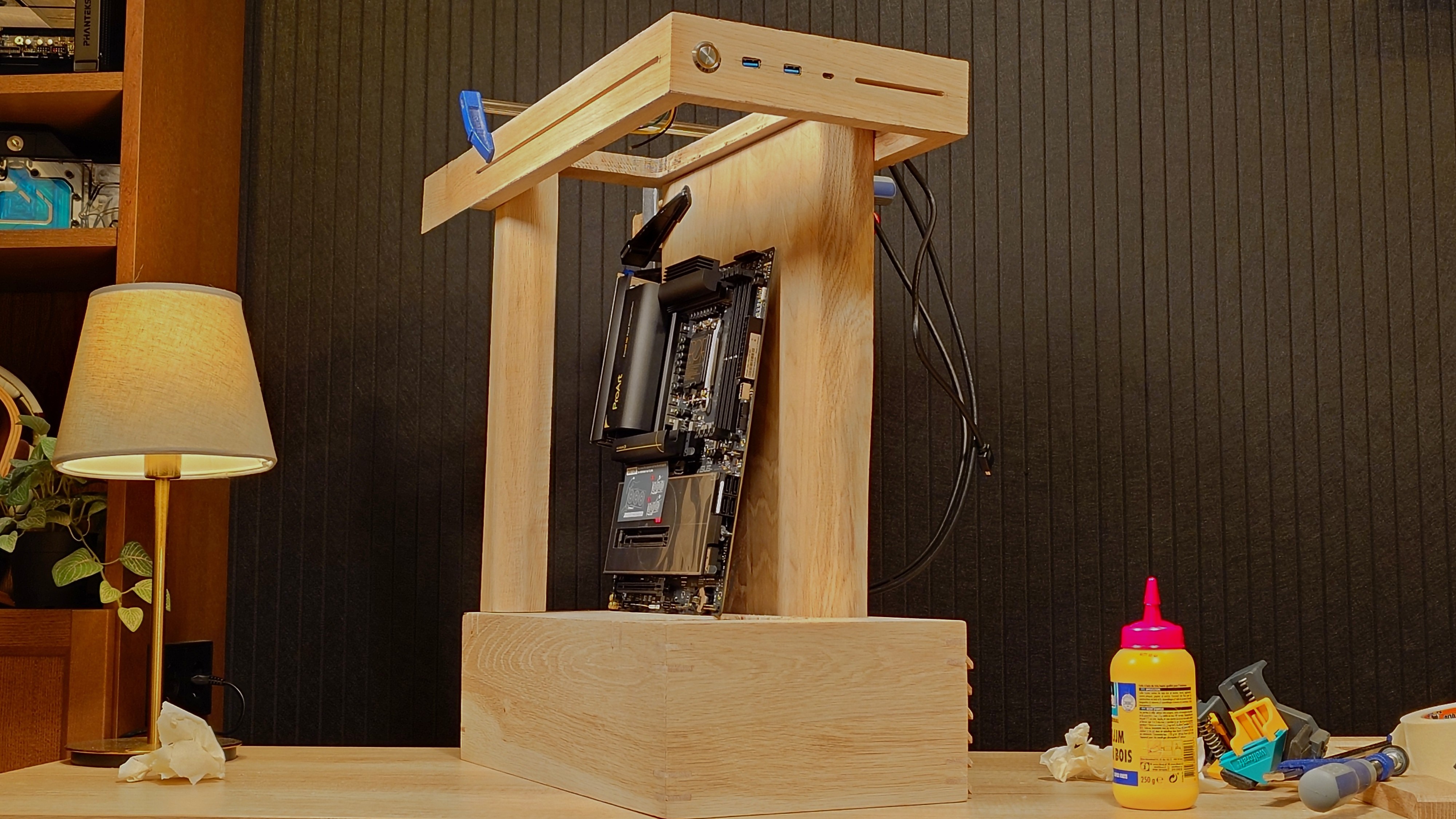

Building the basic shape of the PC didn’t take long. I started by putting the system’s spine on feet, with the intention of carving legs out so that the PSU chamber would appear to float.

Using the circle saw and the miter saw, I then cut up the pieces to make the PSU chamber’s box. I would have preferred to do all with the miter saw for more exact 45-degree cuts, but my saw is too small for the longer cuts along the length of the pieces, so I had to rely on the circular saw, with a guide and a steady hand.

For consistent height between the three side pieces, I cut the entire length of the board in one go, since I was using the circular saw anyway, and then used the miter saw to chop out the left, front, and right sides. As a bonus to this method, the wood grain is one continuous piece along the outside of the PSU chamber, neatly transitioning from the side to the front piece.

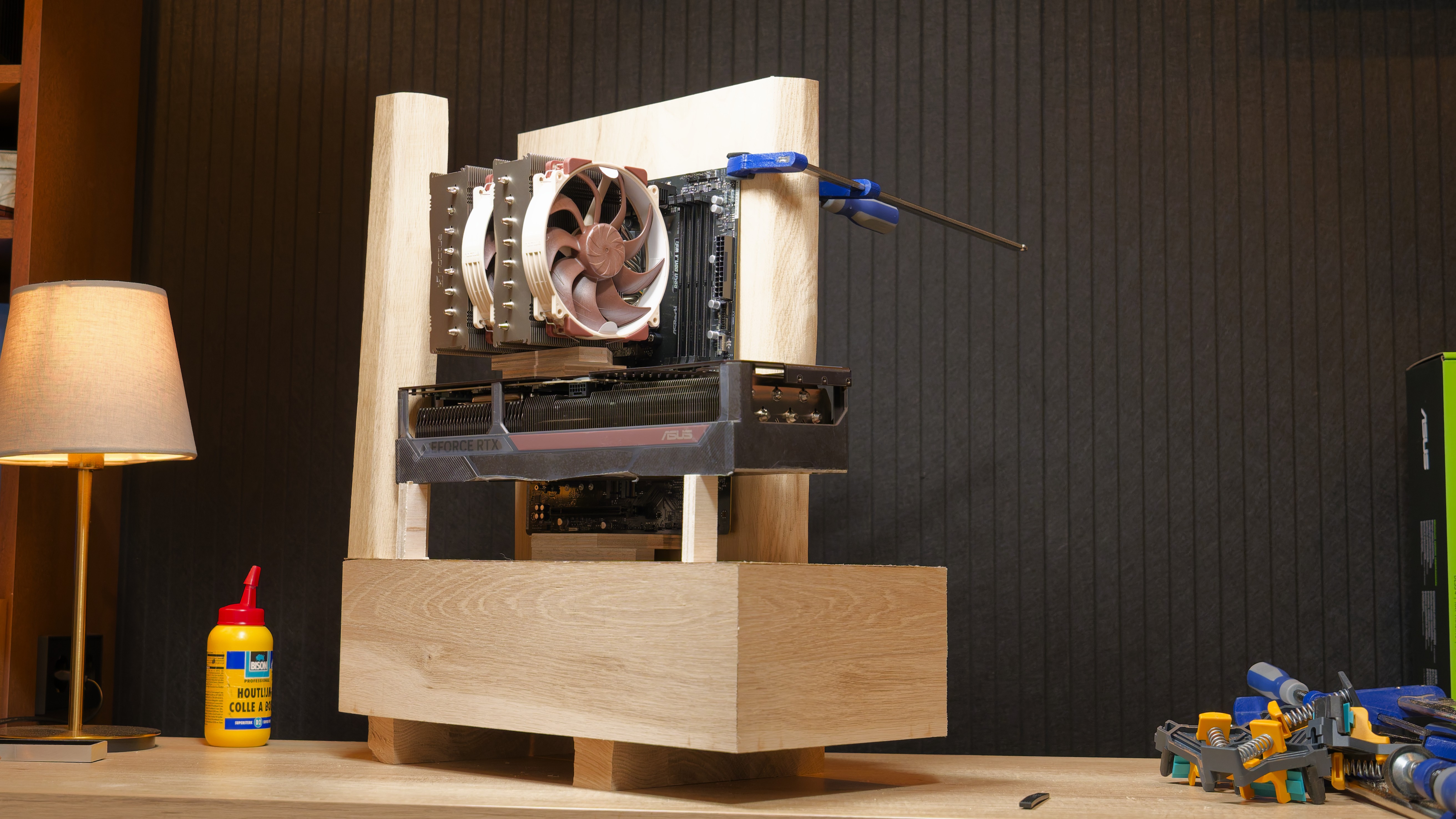

Once this was done, I test-fit some of the components to get a feel for what it was going to ultimately look like. At this point, I decided I didn’t like the feet – by raising them, they made the PSU chamber look far too big and drew too much attention. I wanted a more calm, subtle appearance.

Splines galore

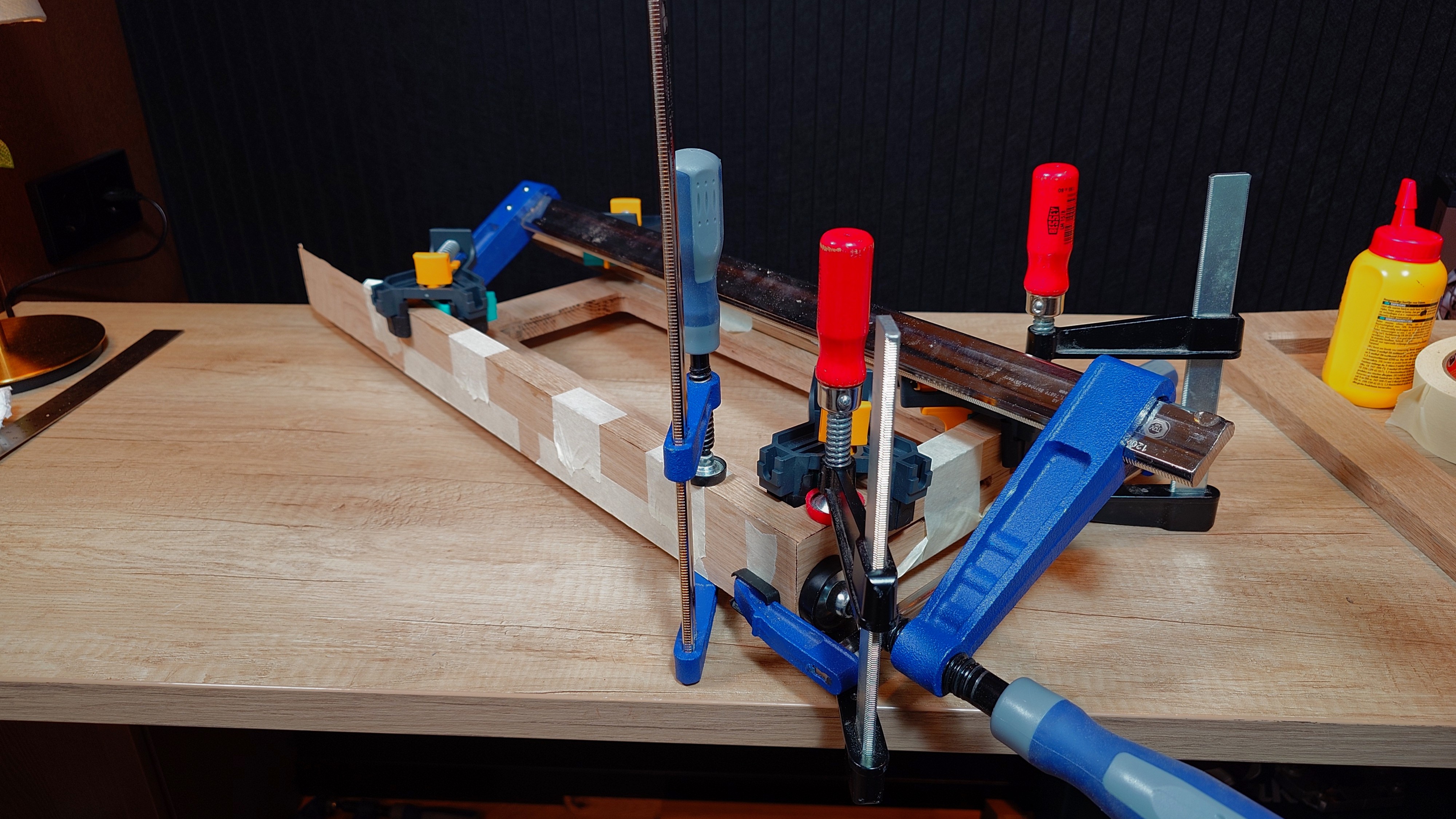

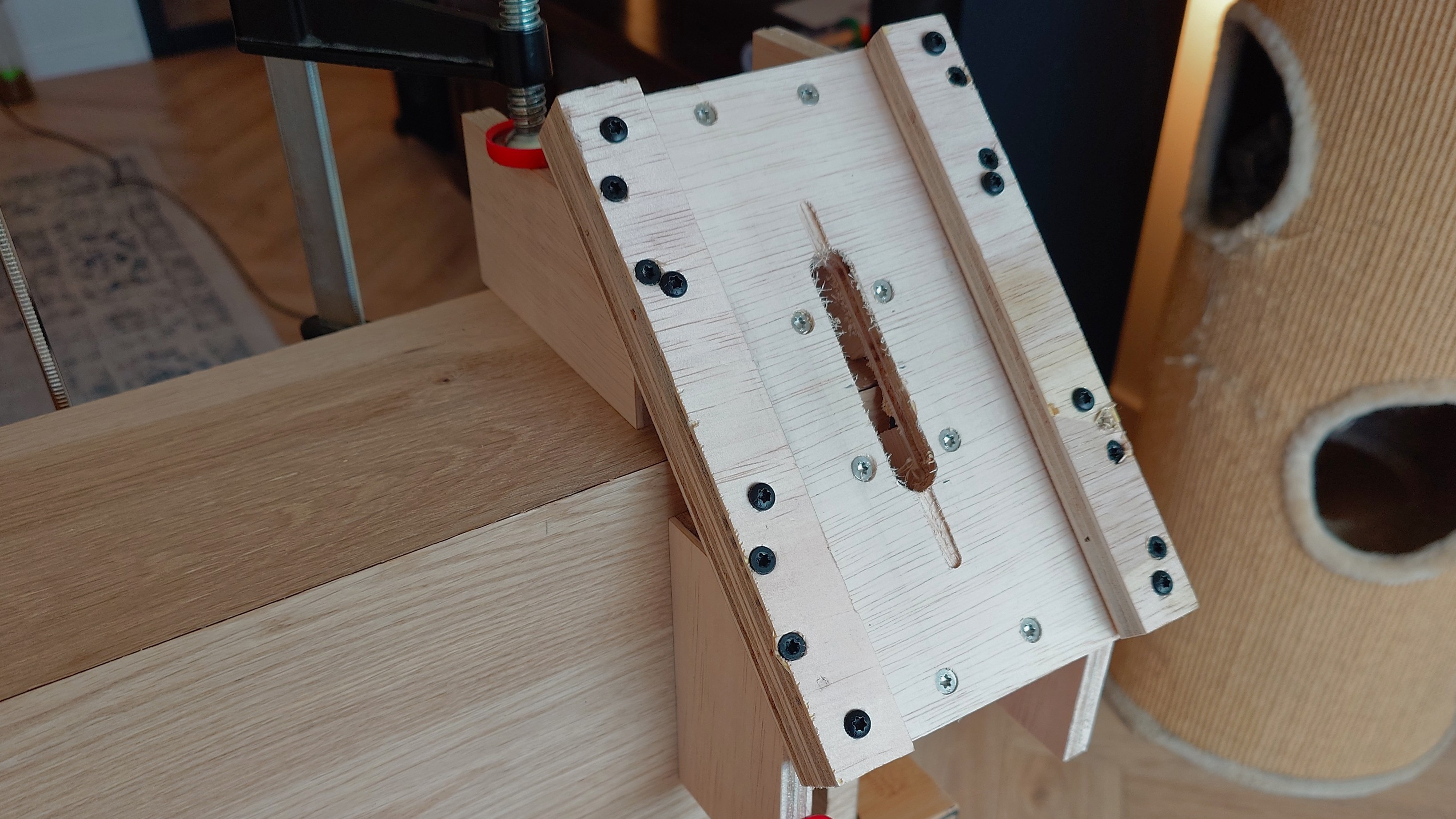

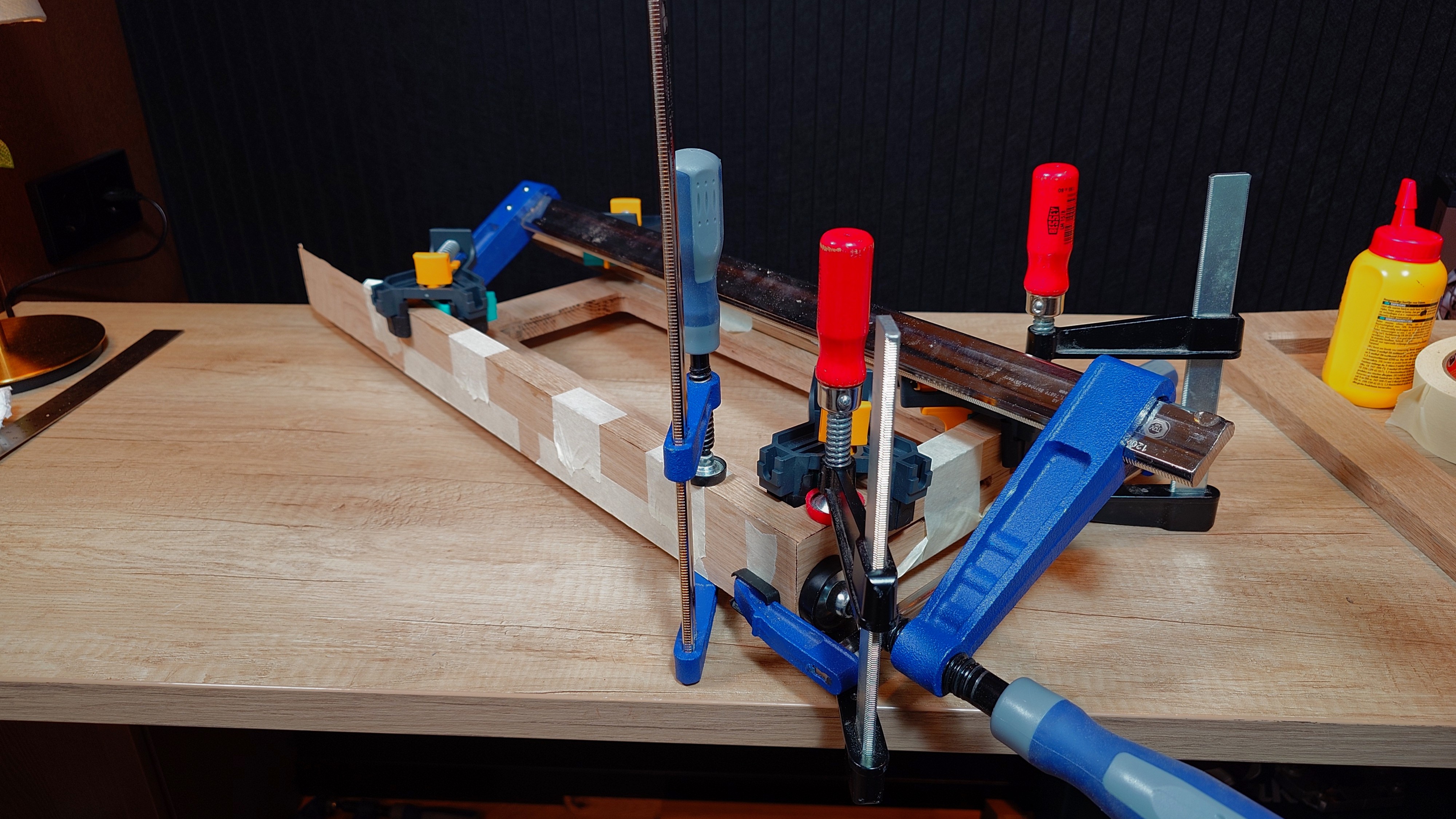

With the PSU chamber’s frame built, it was time to add splines to the joints. For strength, dovetails would have been ideal, but I prefer the appearance of straight lines. For this step, I built a jig from some scrap plywood that I could affix onto a corner, and run the router through at 45 degrees to create slits, which I strategically placed in spots where they would not just add the necessary strength, but also add to the overall visual appeal.

I then pushed the meranti pieces into the slots with glue to ensure full coverage inside. I then sawed off the bits of wood sticking out, chiseled off the excess glue, and sanded the remainder to a level finish.

Then, I used the planing tool to even out the bottom of the chassis to stop it from wobbling, and attached it to the spine with nuts and bolts. I didn't want to use screws to make up for weak wood joinery — any screws or bolts used should be removable for disassembly of the case, and thus, the wood joints needed splines to add the necessary strength.

Part of the design was to have these bolts out in plain sight, so I went out and found the prettiest bolts money could buy. They cost between €2.50 and €4.00 a piece, excluding the washers and nuts.

Part of why they cost so much is because they’re imperial sizing, which isn’t commonly available in the Netherlands, and no metric bolts came with as nice a finish. Look at the lines on the sides of the heads – and the sheer ratio of Allen key socket size to the circumference. Of course, in stainless steel. Robust, yet refined. Worthy of being installed in plain sight in a boutique system build.

The top panel

For the top panel, I decided that a better approach would be to cut the pieces and make all the cutouts beforehand, and only then glue them together and add the splines afterward.

This approach paid off. I had a few slipups with the router, as I forgot to fasten my guide, and by the time I had a front fascia that looked good, I realized that it wouldn’t work anyway: The power button I used would collide internally with the downward-facing LED strip that illuminates the system.

It was one or the other, and I was willing to sacrifice neither. Having run out of scraps, I went out and bought a new oak plank, and cut a new strip with the circular saw and started over. You live and learn.

The top panel consists of two parts: the top and sides as one, with the vent at the top, along with illumination and USB ports on the sides. The second part you’ll see later is a shroud that slots in from below, which holds the fans and covers up the gaps around them. As I put the system together, I realized I may be able to complete the build without an additional support pillar at all.

The Vents: A Sore Point of Frustration

In the design process, I had already decided that the PSU chamber was going to have a vent on top for keeping heat from accumulating, but having decided it was going to sit flush against the desk (instead of levitating with an open bottom), it also needed an intake vent. I didn’t want the intake vent on the user side, nor did I want it at the front, so I decided to make a hole on the right side, in the space of the PSU compartment that sticks out from the spine.

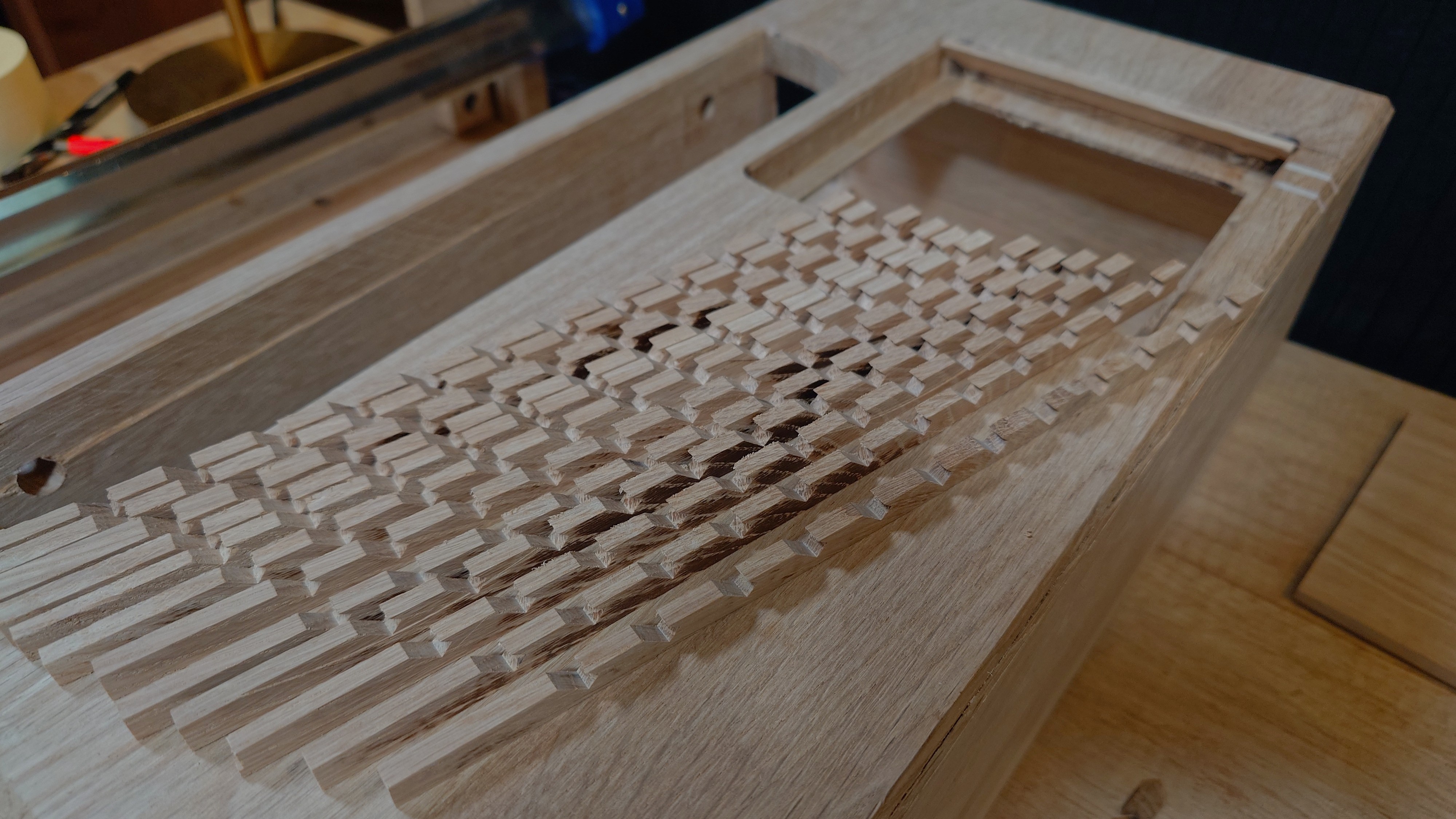

Using a jigsaw, I cut out a 120mm gap for the fan to sit in, and then used the router to cut holders for the fins. The result was… disappointing to say the least. I had done a test piece elsewhere and thought it would look okay, but the router left tons of ugly blowout artifacts.

Of course, I could tidy things up with a chisel and some sanding, so I made some fins by tilting the miter saw 45° to see what it would look like – but even with the fins in place, I was displeased – the fins sticking out looked far more aggressive than the vibe I was going for.

So, once again, I grabbed the router, cleared the angled cuts into a tidy straight line, and left a small lip for the fin holders to glue up against.

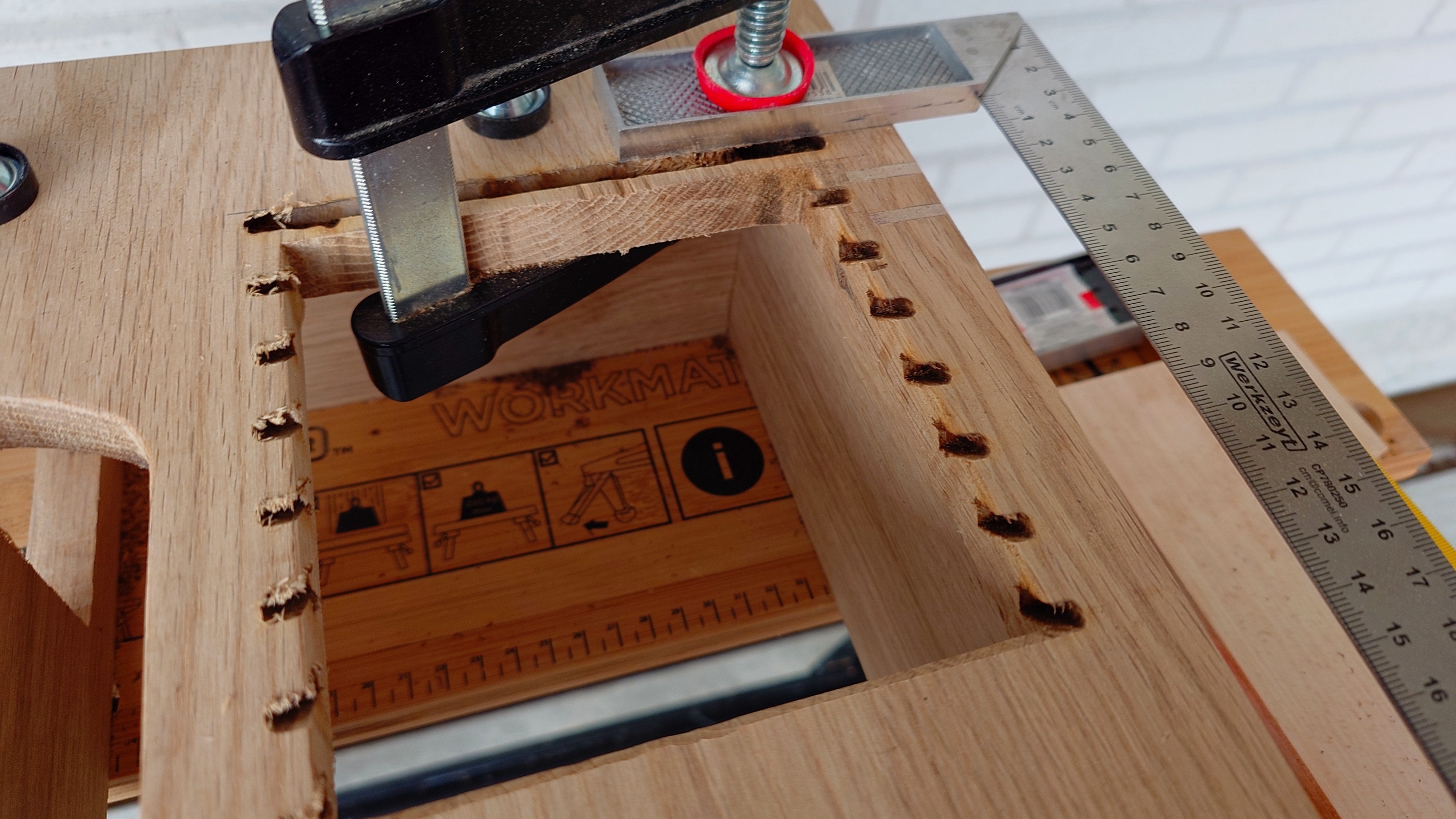

To make the fin holders, I first used the router with the plunge base to flatten a chunk of an oak plank. Then, I used the router again with an angled base to cut 45-degree slits, after which I used the miter saw to cut the slab into strips.

I had decided to make an abundance of holders, as some would get lost to the miter saw inevitably chewing pieces up. And being rather thin, I figured some would break along the way.

I was very happy with these holders as an outcome, and later, when making the fins, it all came together to produce a beautiful end result. I glued the strips in and used the router with a flush trim bit to remove any excess lip I had left earlier.

Routing the cable channels

For cable management, I wanted to cut out grooves in the back of the spine of the PC, where I would use cable combs to create some stunning cable management. For the CPU’s two 8-pin EPS cables, it was a matter of cutting a straight line up and placing a hole to get to things to the motherboard on the other side.

But for the 24-pin motherboard cable, I had to make a wide turn, so I built a jig that allowed me to rotate the router along a center point, like a compass. A template would have worked too, except that I had no means of making a template to the correct circumference, and I didn’t have any shallow enough template bits with a bearing at the nearside of the router – the bits I did have would cut deeper than I wanted the groove to be.

In addition to the 24-pin motherboard cable and two 8-pin cables for the CPU, I also cut out two grooves for the cables going from the PSU compartment to the top panel, a small groove for the front I/O cables, a large cavity near the PSU area, and a small cavity at the top where the RGB controller would sit, as there was no space left in the top panel.

I hadn’t yet cut out the holes for the GPU brackets to attach, nor had I added the threaded inserts for the motherboard. I did not want to sand the gold finish off the threaded inserts during a later stage, so I only inserted these after applying the final finish. Once the motherboard was installed, I could determine the exact position of the GPU brackets.

Beveling all the edges

Throughout the process of building all the pieces, I frequently switched the router to a 45° chamfered bit to trim all the edges of the workpiece, with larger cuts on the boxy bits, and smaller cuts on the spine, along all grooves and cutouts, for a smooth and soft-looking finish.

The Fins

The fin holders I had created earlier looked tidy, but weren’t very consistent with their thickness – without storage space for a proper flattening jig, my hand-guided results were a fraction of a milimeter off across the plane, and therefore, some of the fins sat higher up than others.

Their spacing was good however, so I made new fins and simply sanded down the bits that stuck out from the top of the panel, leading to a smooth, flush finish with the top of the vents. Once sanded down, you couldn’t tell that they all have ever-so-slightly different sizes.

Finishing Touches

Finally, it was time for some finishing touches before finishing each wooden piece itself.

Initially, I hadn’t planned on doing much about the back of the PC, as well, it’s the back. Who cares? But after having sunk this much time into it, it felt a shame to leave it like this. I already trimmed things up with the miter saw to make it all flush, but decided it needed a “veneer” to cover things up.

I also removed the large bolts holding the fan shroud entirely, as I didn’t like them in this part of the PC. Instead, I used a cleat method, and countersunk the bolts at the front to sit flush, as to not distract from the components that were to be installed in the system.

Yuck. The rear of the PSU compartment also needed a veneer.

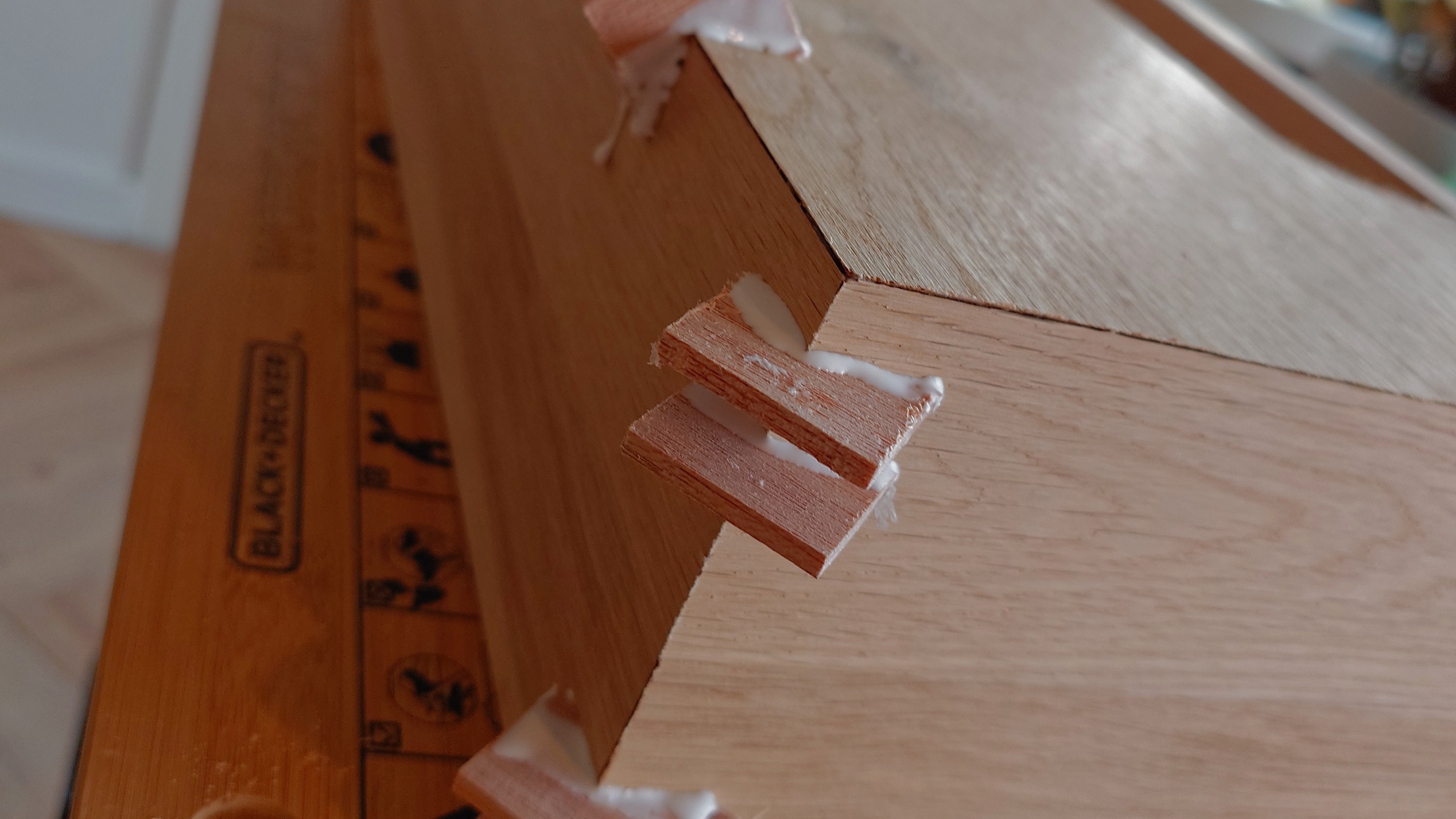

The picture above well describes the final stages of what the woodworking process felt like. I had bumped a splinter off the back of the PSU compartment while I sawed some off for the veneer, so I glued it back on. Also, one of the splines hadn’t pushed in far enough during gluing, so I cut a tiny piece off of some scrap meranti and glued that in, then sanded it flush.

On the top panel, these two splines also had burrs that broke off during sawoff. If you look carefully, you can see the difference in grain pattern on the right one, which had been fixed earlier.

Sanding and Finishing

I’ll skip the part where I talk about the sanding because… it’s boring, takes a long time, and I could write a book about all the steps I took to find the right method. Instead, I’ll let the picture below do the talking. It had reached freezing temperatures outside, so I freed up this room in my house, moved almost all the furniture to the living room, and spent three days sanding the project. Bless my neighbors.

For the final finish, I opted to use Rubio Monocoat. It’s a pricier finish, but it’s a linseed-based hardwax that bonds with the wood grain at a molecular level. This means that you cannot create overlapping lines the way a film finish would, and with all the nooks and crannies this build has, a film finish was going to be very difficult to apply properly – I really did not want to end up with a droopy mess.

Rubio, on the other hand, is fairly simple to apply. Just wipe it on, wait 5 minutes, wipe things off, and buff. Better yet, Rubio performs best when the workpiece is sanded only up to 120 grit, as higher grits close off the wood pores and stop it from taking in the pigment. This saved me a lot of time sanding, as if three days of straight sanding weren’t enough.

For good measure, I went over the pieces with my DA polisher as a final step, which led to a beautiful and even finish.

The body pieces I finished with the color “Arabica,” a rich brown with a warm reddish tint, somewhat matching Noctua’s own colorway. For the spine and fins, I opted to use Mist 5% (pictured on the left of the three samples), as this is a color that has a bit of cream white pigment in it to counter the natural darkening that an unpigmented oil (middle) would cause, keeping the spine and fin pieces almost entirely true to their original colors. Moreover, both colors fit the Noctua-themed build almost perfectly.

Bits and Pieces

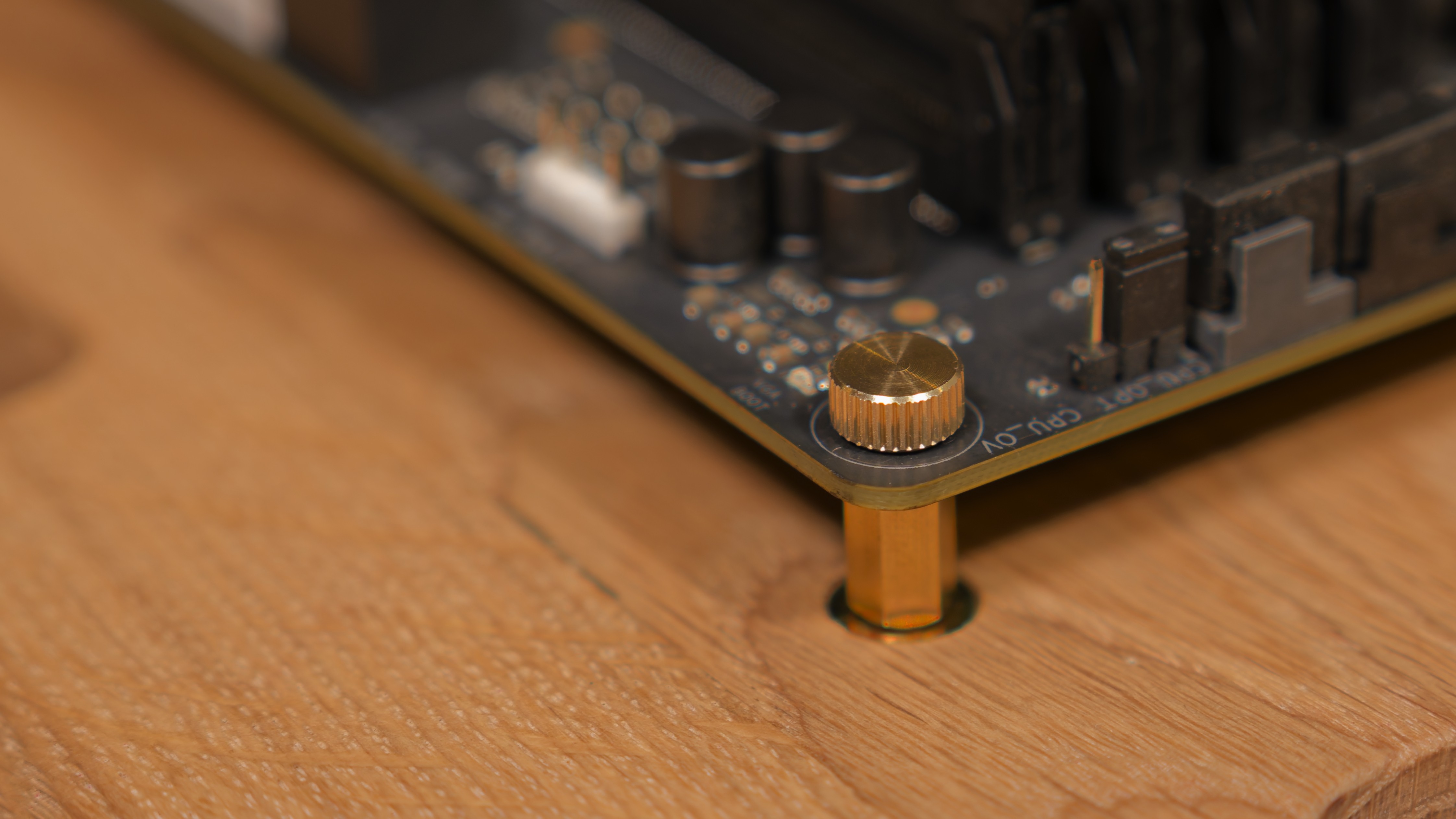

With the finish applied to almost all pieces, I could install the threaded inserts, the brass standoffs, and test-fit the motherboard. With the Asus Z890-Creator in place, I determined how I was going to support the GPU and built the GPU holders.

The Asus x Noctua RTX 5080 is a thing of beauty – it’s one of the biggest graphics cards money can buy, weighing in at almost 6 pounds. But with its classy colors, I didn’t want to do it a disservice with a trashy vertical mount. Instead, I opted to build a hidden-in-plain-sight mount for the graphics card that would make it appear unsupported from the side and front profile, for a subtle, creative touch.

This GPU occupies four slots, so I could easily “hide” the L-shaped support behind the GPU without any protrusion. Because it also has to carry a decent amount of weight, I used the grain pattern in two different directions by applying a veneer to the outside of the bracket for added strength, and a tidier visual finish.

While making the GPU support bracket at the rear and the anti-sag nub, I also routed out two oval-shaped holes in the motherboard tray for their bolts to fit through, being oval by just a few millimeters, so I could adjust them up/down to get the GPU perfectly level during final installation. The extra pieces were then finished in Arabica, and the fresh cuts in the motherboard tray were tidied up.

For the motherboard, I found galvanized threaded inserts to match the gold accent color of the motherboard and RAM, with an M4 inner thread, 10mm brass standoffs with M4 outer and M4 inner thread, and brass thumbscrews with – you guessed it – M4 outer threading.

A support bracket for the power supply was also built so that no screws would be visible from the rear of the build.

And a support structure was made for the lower compartment fan to adapt it to the larger vent. Of course, I could have just grabbed a 140mm fan, but where would the fun be in that?

I also stamped each of the fins with a letter and number during sanding so that I would know which fin belonged in which position in the case – the six side fins for the intake wouldn’t be too difficult to figure out, as they’re much smaller than the rest, but the remaining 29 fins would be a nightmare to pick out without some sort of guide.

Yes – I know stamping each of the 35 fins with their intended position seems like an insane level of detail, but I’m telling you: The 15 minutes it took to do this is the kind of foresight I wish I had earlier on in the build process.

At Last, The Case is Finished!

Next, let’s install a PC into this owlet.

Niels Broekhuijsen is a Contributing Writer for Tom's Hardware US. He reviews cases, water cooling and pc builds.