Tom's Hardware Verdict

A solid entry in the sub-$1,000 prosumer market, the Creality Falcon A1 Pro features a 20W diode laser in a fully enclosed build volume and software that will have users up and running in no time.

Pros

- +

Fully enclosed design with safety features

- +

Air assist for clean cutting

- +

Quick release toolhead with automatic focus

- +

Intuitive Falcon Design Space software

Cons

- -

LCD interface feels like an afterthought

- -

Weak exhaust fan

- -

Safety goggles not included

Why you can trust Tom's Hardware

The Creality Falcon A1 Pro is a 20W diode laser engraver that brings a full enclosure, automatic focus calibration, and a variety of safety features to the sub-$1,000 price point. An actively vented exhaust at the rear of the unit can be attached to an external smoke purifier, and the 358 x 268 mm build area is large enough to fit commonly available 10 x 10 inch sheets of plywood.

The unit used in this review is the $949 Basic Pack bundle, which includes the Falcon A1 Pro equipped with a 20W blue laser diode and a honeycomb riser platform. Designed as a platform with multiple available upgrades, the Falcon A1 Pro can also be equipped with a 2W IR laser for engraving on glass and metal, a rotary attachment for engraving on cylindrical objects, and other various upgrades.

Creality clearly invested time and effort into the build quality of the Falcon A1 Pro, and the overall industrial design allows it to stand out compared to the look of aluminum extrusions and loose wires typically seen on less expensive laser engravers. Throughout testing, I was impressed with the hardware and software experience of the Falcon A1 Pro and can see this laser being a popular choice for users who want something a bit more polished than a simple entry-level machine, but don’t want to make the larger investment required for a CO2 laser like the xTool P2.

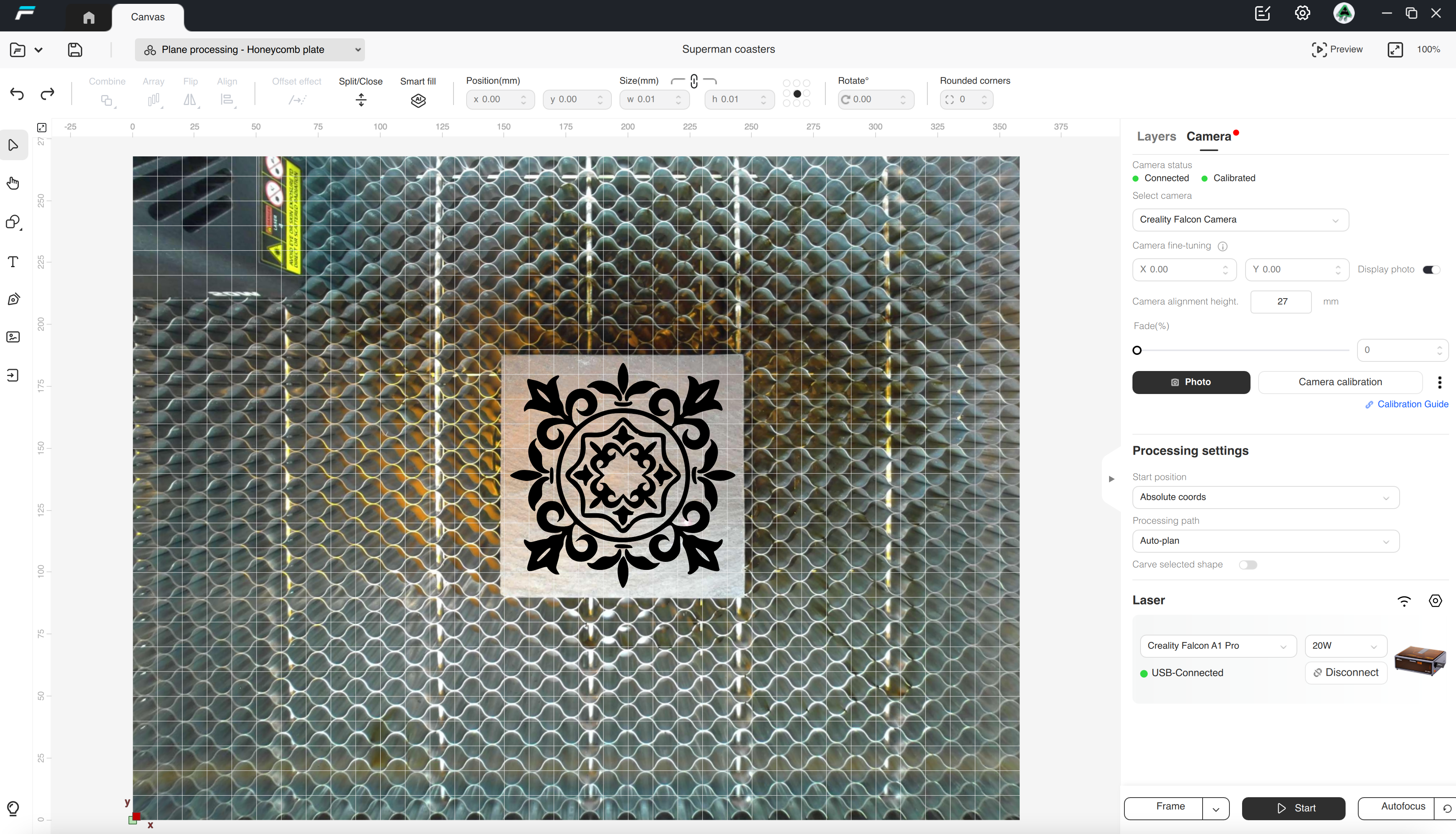

The Falcon A1 Pro uses the free Falcon Design Space software for laying out and processing jobs and is also compatible with LightBurn and LaserGRBL. Falcon Design Space offers projects for beginners, recommendations for parameters based on material choice, and the integrated camera can project the job on a workpiece in the digital design area. The Falcon A1 Pro doesn’t quite make our list of the best laser cutters and engravers, but it’s still worth investigating for anyone interested in a more polished hardware experience while staying under $1,000 for the base unit.

Specifications of Creality Falcon A1 Pro

Machine Footprint | 22.32 x 18.43 x 8.31 inches (567mm x 468mm x 211mm) |

Engraving Size | 14.09 x 10.55 inches (358mm x 268mm) |

Laser Type | Diode, Class 1 |

Laser Power | 20W |

Laser Spot Size | 0.08mm x 0.1mm |

Laser Wavelength | 455nm |

Enclosure | Integrated |

Cutting Platform | Removable |

Air Filter | Optional |

Connectivity | USB, Wi-Fi |

Basic Bundle Price | $949 |

Creality Falcon A1 Pro: Included in the box

Image credit: Tom's Hardware

Image credit: Tom's Hardware

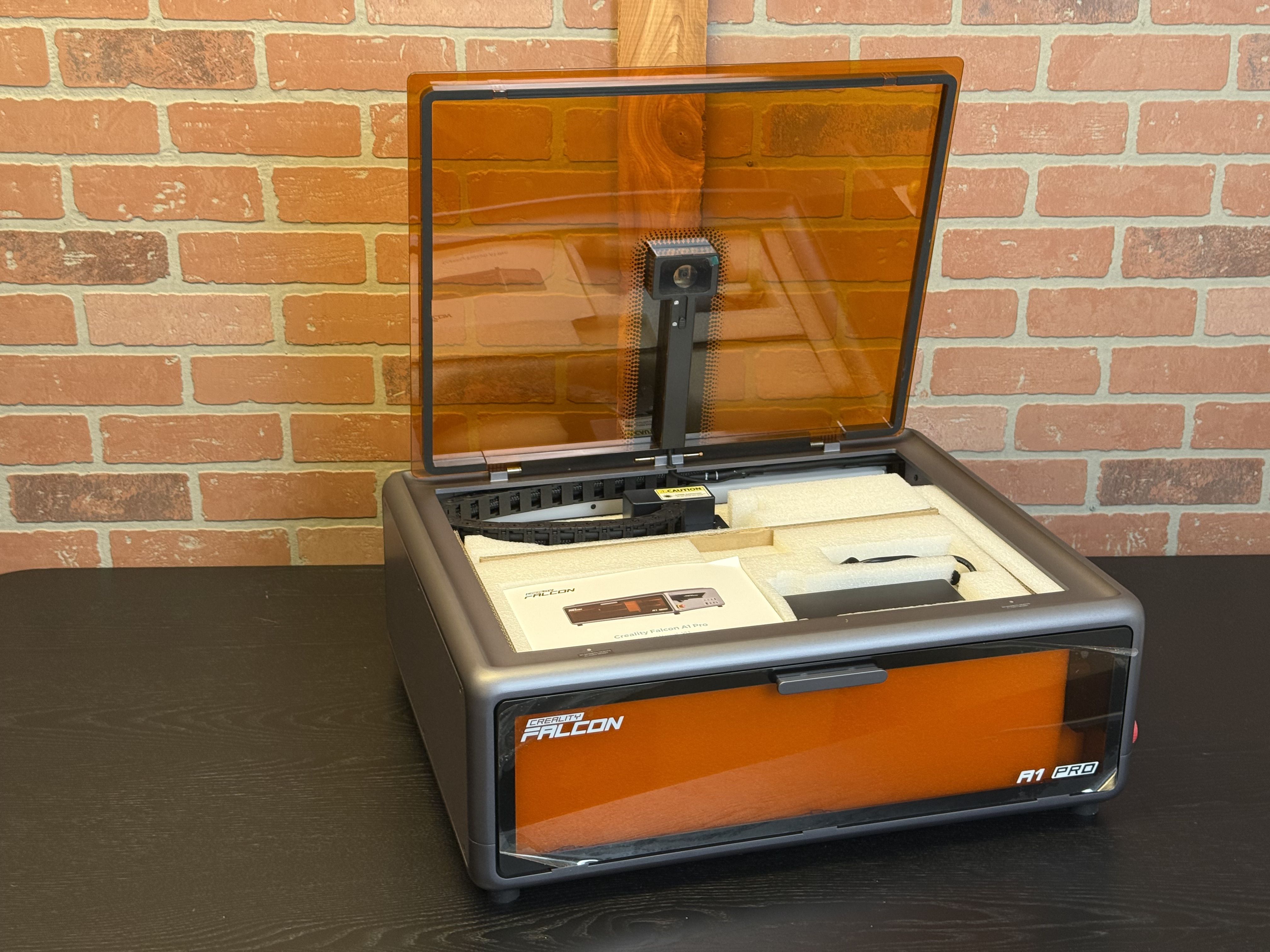

The Creality Falcon A1 Pro arrives completely assembled, with only a few connections required for the air assist, air filter, and external LCD screen. The components and accessories have all been carefully packed inside the unit, which also prevents the gantry from moving or bending during shipping. The top and front acrylic lids have a protective sticker applied to them, which can be easily removed before use. As far as assembly goes, this Falcon A1 Pro is simple, well-documented, and should be easy for even a complete beginner to put together in well under an hour.

The Falcon A1 Pro includes all the tools and cables required for operation (screwdriver, hex keys, etc.) as well as a flexible hose for the smoke purifier, an external air assist unit, a calibration board, and a single sheet of material for the initial camera calibration. The product manual is a refreshing addition, and it includes unboxing, usage, and troubleshooting information in multiple languages.

The air assist unit isn’t mentioned on the Creality site, and it’s also not present on the list of included accessories. I was surprised to see an external air assist unit included with the machine, as I didn’t see it included anywhere on the product page and it’s not mentioned in any of the advertising. Regardless, it’s a welcome addition and a critical part of the system to create clean and char-free engravings.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Notably absent from the included accessories are any kind of safety goggles, a surprising omission for a laser engraver that has a base price of nearly $1,000. While the UV shield acts as a filter for laser radiation, goggles are an important piece of PPE when using a laser to help prevent damage to your eyes.

Design of the Creality Falcon A1 Pro

Image credit: Tom's Hardware

Image credit: Tom's Hardware

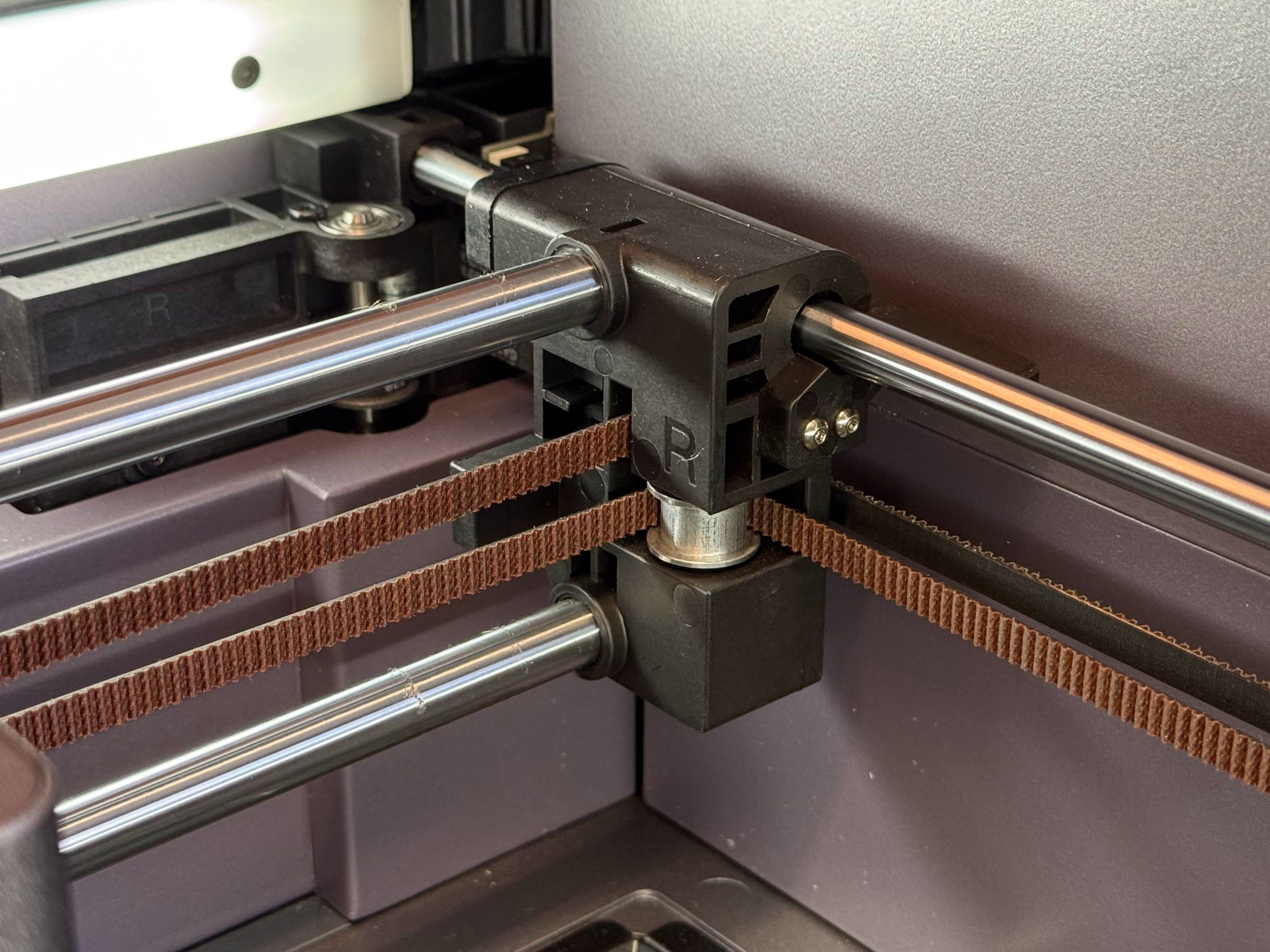

The Creality Falcon A1 Pro is a well-designed machine, with smooth corners and countersunk bolts giving it a very intentional appearance. The build volume is illuminated with a bright array of LEDs, and the automatic focusing laser is concealed in the front right corner. The toolhead gantry moves without friction across a pair of smooth rods, and the toothed belts have an exposed tensioner to adjust if needed.

Unlike the lower-cost Creality CR Falcon, the Falcon A1 Pro is fully enclosed and contains multiple safety features and sensors that make it a more attractive option for prosumer or shared use. The overall build quality of the Falcon A1 Pro is solid, and it seems like Creality is really paying attention to the important little details to justify the higher price of the machine.

The input/output is on the side of the Falcon A1 Pro and includes ports for power, air, USB, and optional connections for the rotary kit and a USB drive. There is also a lockout feature that requires a special key to activate the machine, preventing it from being used by anyone who does not have access to the key. As far as safety features go, this is a very useful one and critical in any shared-use environment, such as a makerspace, R&D lab, or factory floor.

Image credit: Tom's Hardware

Image credit: Tom's Hardware

The laser toolhead of the Falcon A1 Pro is removable with only two sliding levers, so swapping it out takes under a minute. Creality currently offers two toolheads for the Falcon A1 Pro: the 20W diode laser for general non-metal cutting and engraving and the 2W IR laser for engraving on metal and glass surfaces. The toolhead is mounted on a sliding track, so the automatic focusing (more on that later) can be done without any manual intervention.

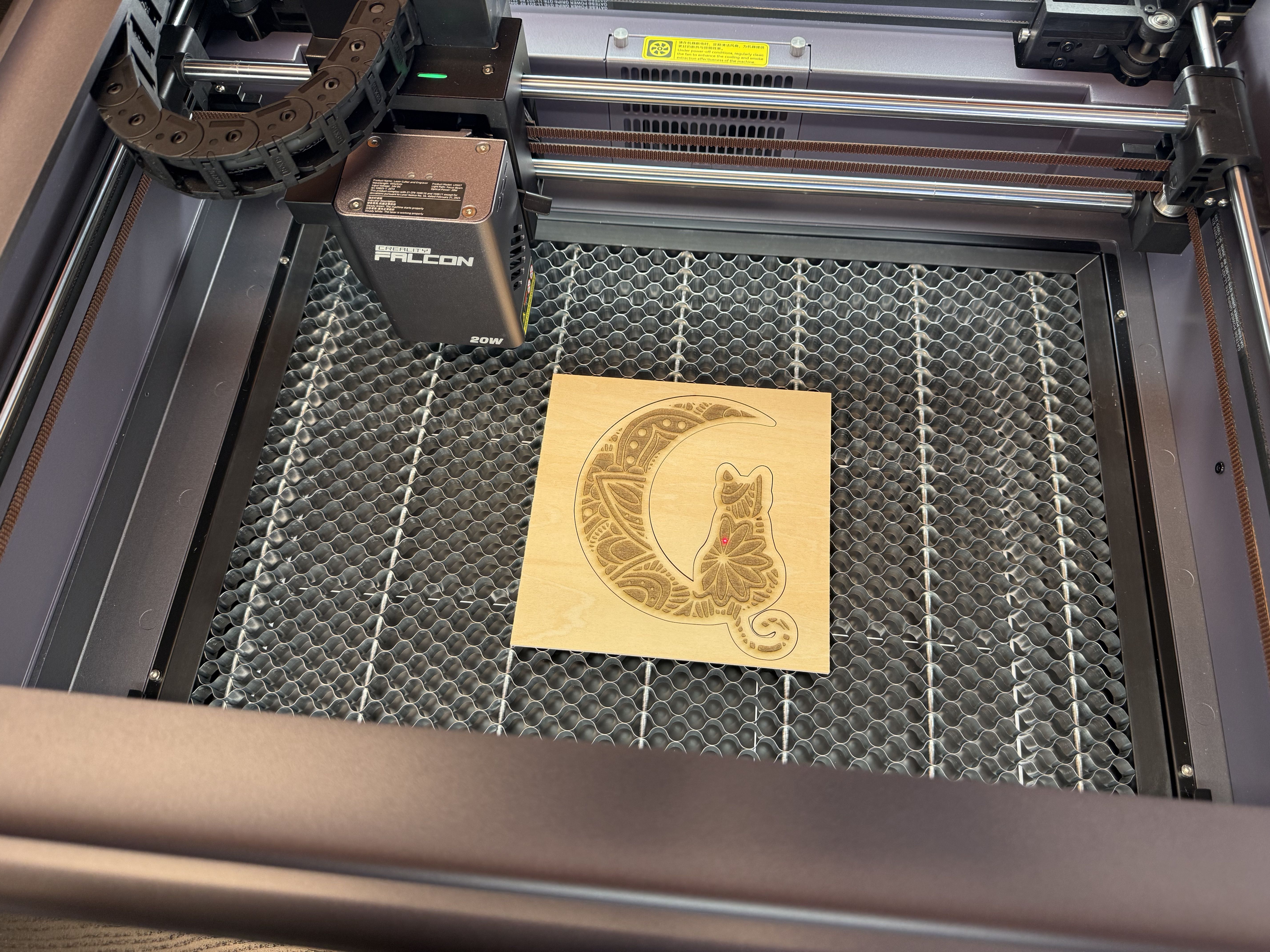

The optional $69 honeycomb for Falcon A1 Pro provides an elevated platform for laser cutting, which allows for airflow underneath parts being cut. Honeycomb platforms have a dramatic impact on the quality of parts produced on laser engravers, and adding this platform should be the first thing you do if you plan on producing parts to sell or even give away. Without this platform, the workpiece will rest directly on the metal baseplate of the Falcon A1 Pro, and parts will require cleaning immediately after processing.

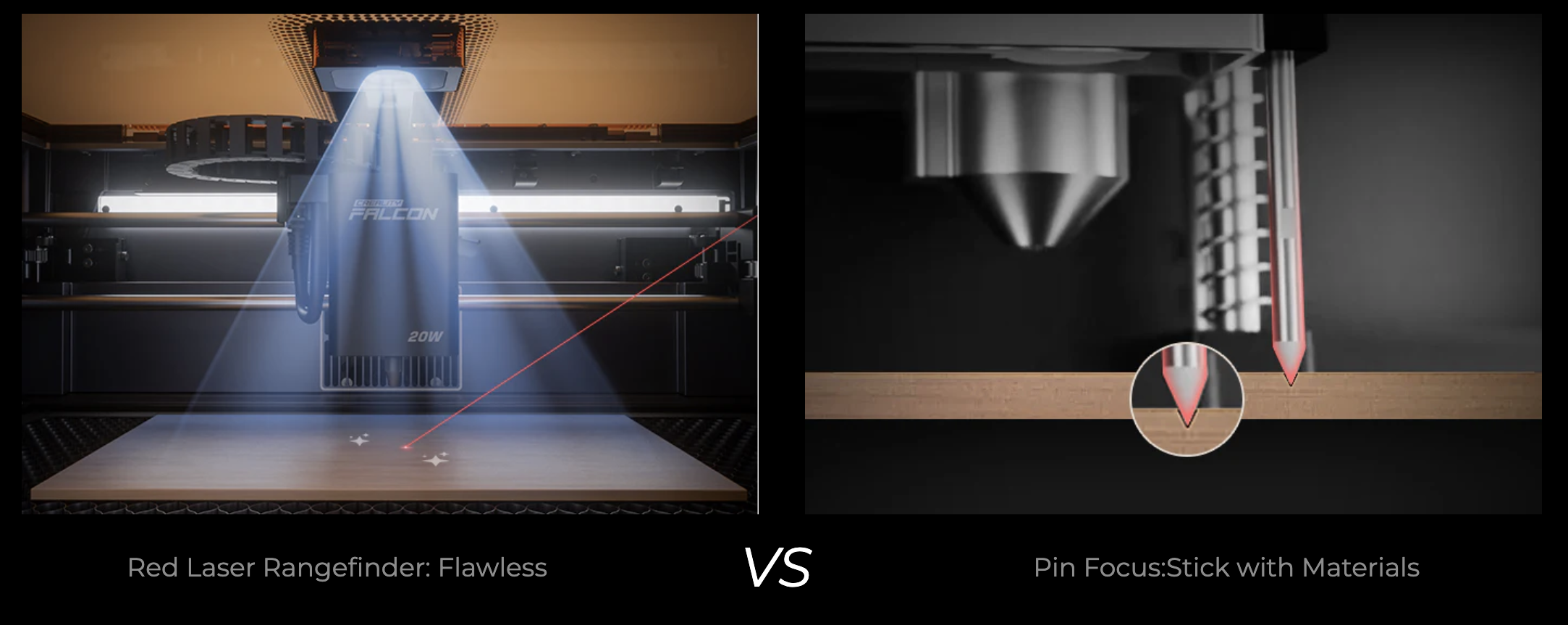

The Falcon A1 Pro is capable of automatic leveling to detect the height of a piece of material, a useful addition that keeps users from having to manually set the height for every single processing job. The laser is integrated into the enclosure and allows for precision calibration in only a few seconds. I used the automatic calibration throughout the review and had no failures or issues with the feature.

Image credit: Tom's Hardware

Image credit: Tom's Hardware

The Falcon A1 Pro has a camera integrated into the top cover of the unit, an invaluable tool for visualization and laying out complex jobs across multiple workpieces. An interesting feature is the sliding cover, which can be raised up to block the view of the camera. This cover is actually inside the acrylic cover of the camera, which is something to note if you’re concerned about smoke eventually working into the enclosure and obscuring the view of the camera.

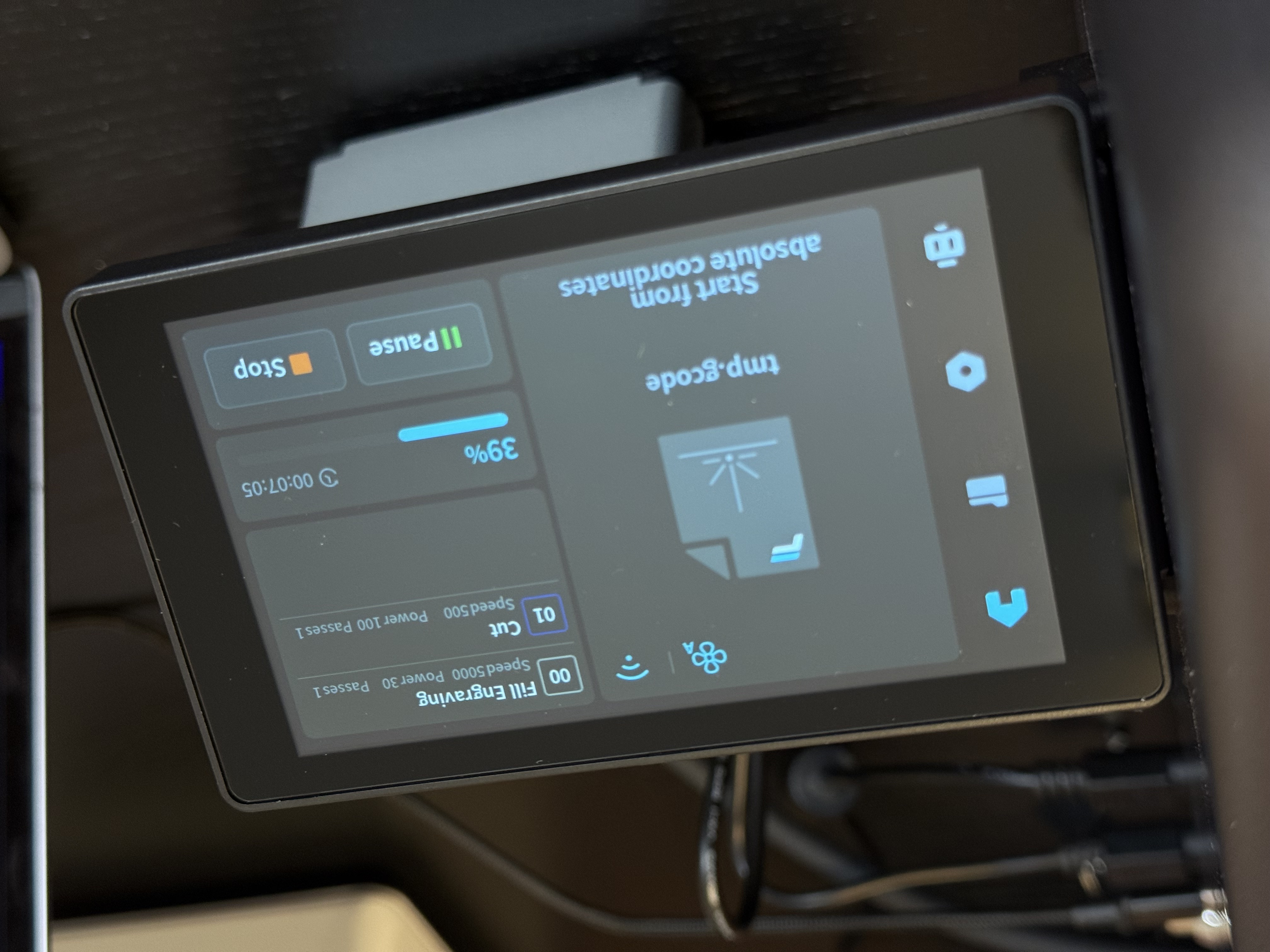

The LCD offers a user interface similar to a modern 3D printer with a list of jobs, machine settings, and tools available. The placement feels like an afterthought, and I found myself being careful when moving the unit to avoid snapping it off or breaking it from the bracket that attaches it to the machine. While I was very happy to have an interface on the machine to track engraving time and progress, it’s easy to imagine that this will be a frequently replaced part.

There is an Emergency Stop (E-Stop) button located directly under the screen on the right side of the unit, something typically seen on industrial hardware and machinery. Given the high power of the laser and typically flammable work material, the E-Stop is an excellent addition by Creality to increase the safety of the unit and make it easier to disable if something unexpected occurs. The Falcon A1 Pro also has a flame sensor, which immediately disables the unit if an open flame is detected, something I did not experience during testing.

Smoke Purifier for the Creality Falcon A1 Pro

Included with the review unit was the $179 Creality Falcon Desktop Smoke Purifier, a small dual-filter purifier designed to remove smoke and odor from the unit during the engraving and/or cutting process. I was surprised at the size of the filter, which measured around 7.3 x 7.3 x 8.1 inches and weighed a little over 8 lbs. This small and compact unit fits easily on a desk, and is clearly intended for home workshops where space is at a premium. On the product page, the “68dB Quiet Working” volume is mentioned before the filtration, which I took as an indicator of Creality’s priorities with this unit.

The Desktop Smoke Purifier has an advertised airflow of 115m³, significantly less than the 300m³/h airflow of the more expensive WeCreat Fume Extractor. The three speeds of the Desktop Smoke Purifier are quiet and not particularly disruptive, but I found that the filter was easily overwhelmed during cutting and was not able to effectively filter smoke from the unit. Even with the unit at the highest setting, cutting through plywood often resulted in smoke that lingered in the unit even after the processing was complete.

While it is available for a fraction of the price of larger filters, I think there’s a bit of a mismatch in the intended use of the Desktop Smoke purifier and the capacity of the unit. Using a smaller unit like this in a home office or workshop is a quick way to fill a room with smoke. In addition, the filter lacks an exhaust to vent outside, instead sending the exhaust directly out the bottom of the unit.

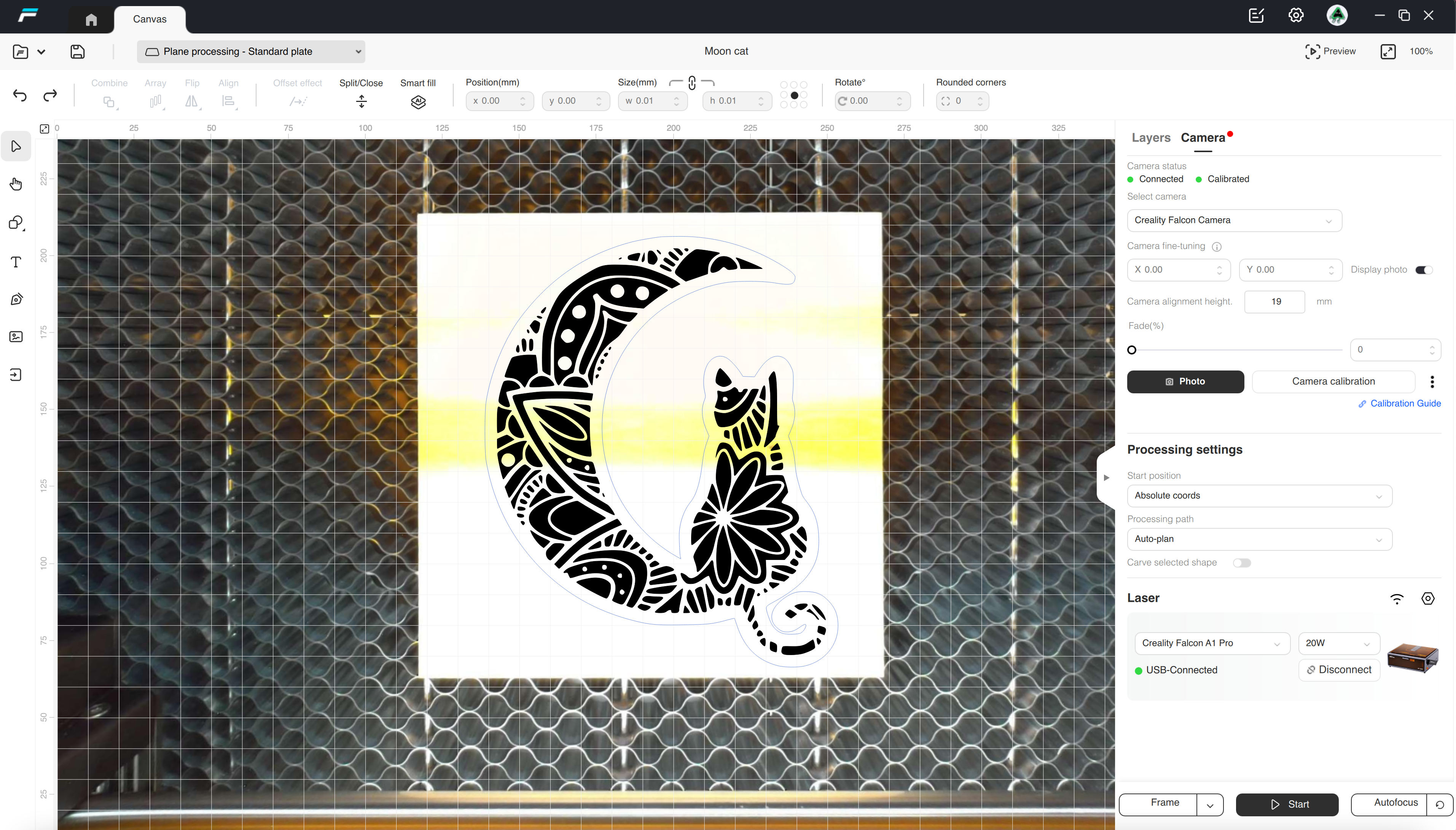

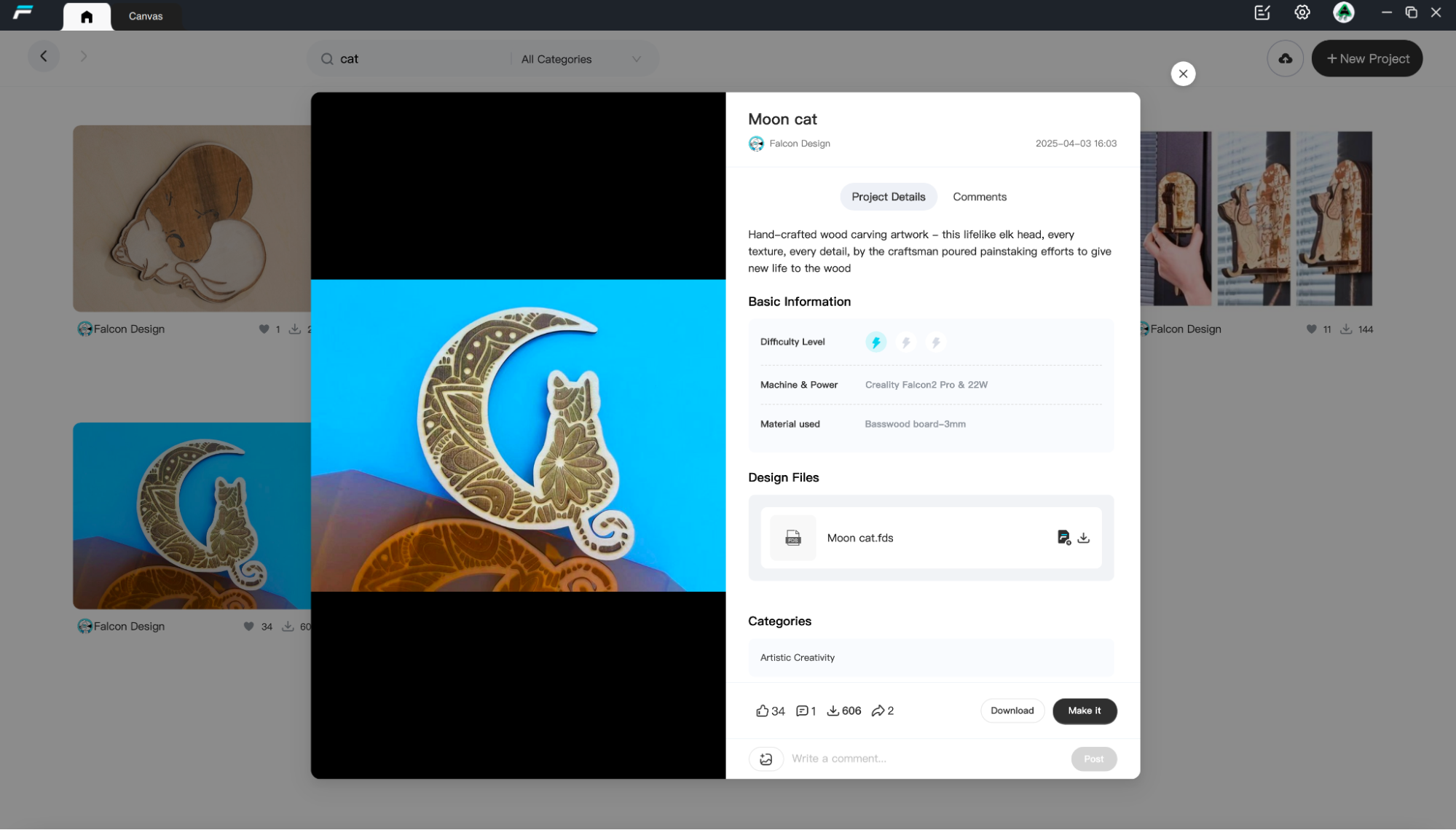

Software for Creality Falcon A1 Pro

Creality Falcon Design Space is a first-party software app that supports Mac, Windows, and mobile devices (iOS and Android). The interface will be familiar to anyone who has used xTool Creative Space, WeCreat MakeIt!, or LightBurn for controlling a laser engraver. Falcon Design Space allows users to adjust all the parameters you’d expect (speed, power, processing order), as well as basic image editing tools like cropping, offsetting, and similar operations.

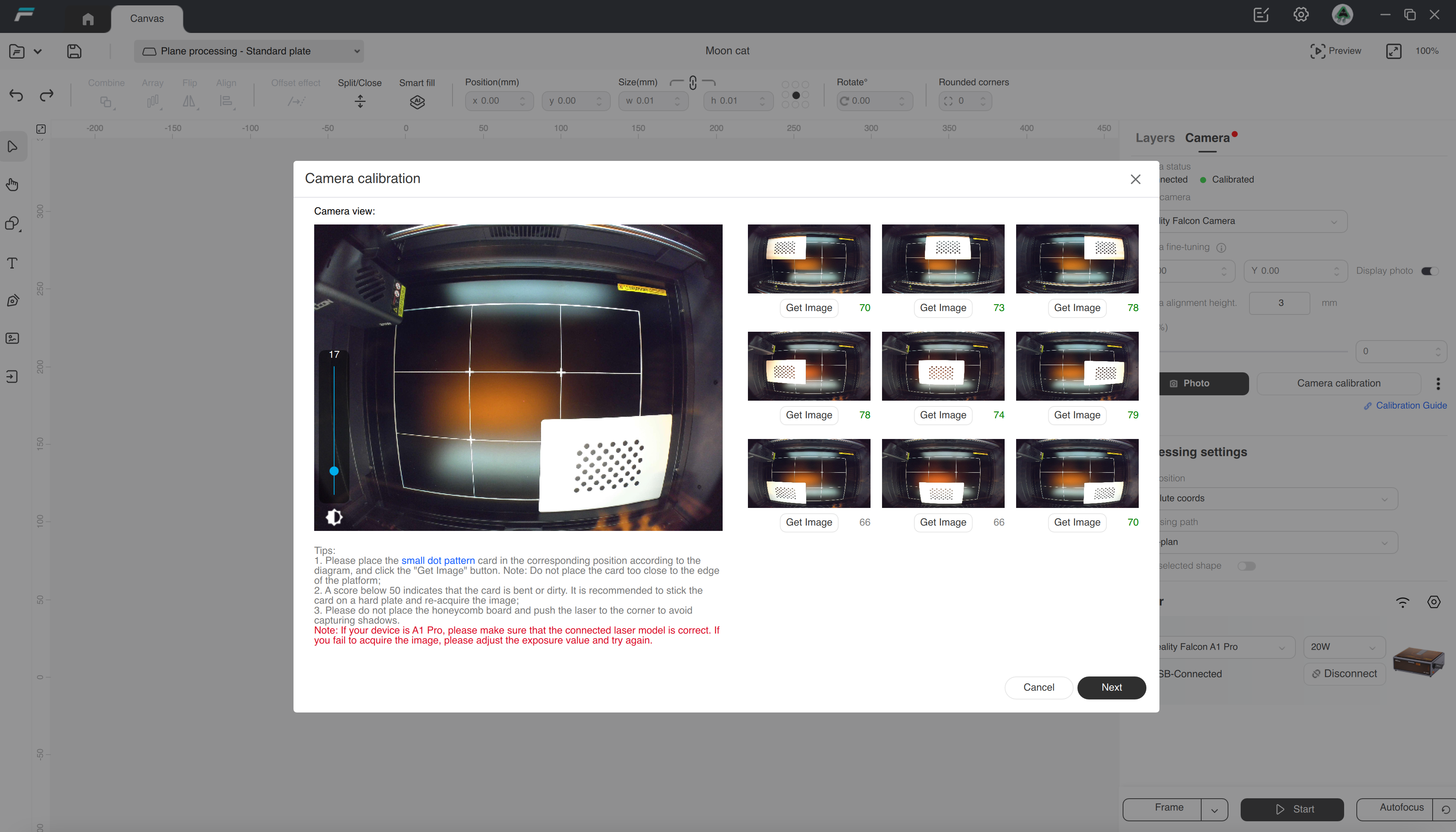

Falcon Design Space also has a live view mode using the integrated camera, which is an invaluable tool for laying out jobs on material when a precise preview is required. The camera on the demo unit required calibration before use, which is performed using the included calibration sheet and takes about 10 minutes to complete.

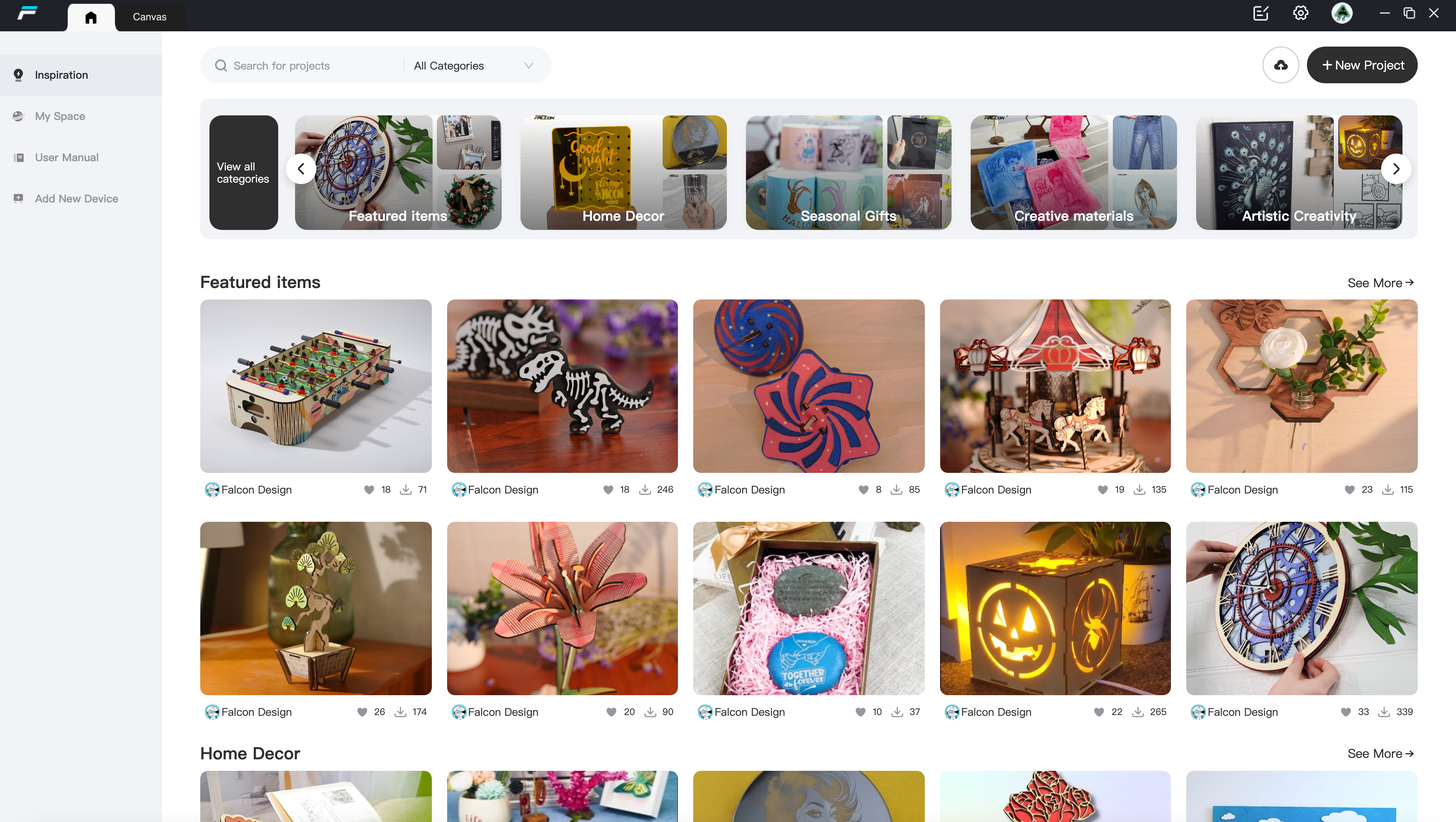

Included in the Falcon Design Space software is a robust selection of projects specifically designed for a variety of materials, occasions, and skill levels. I’ve found catalogs like this are a great way to get started with the laser to understand how to create products and models without also requiring a background in graphic design. While writing this review, I used several projects from this catalog and was generally satisfied with the level of documentation provided by Creality.

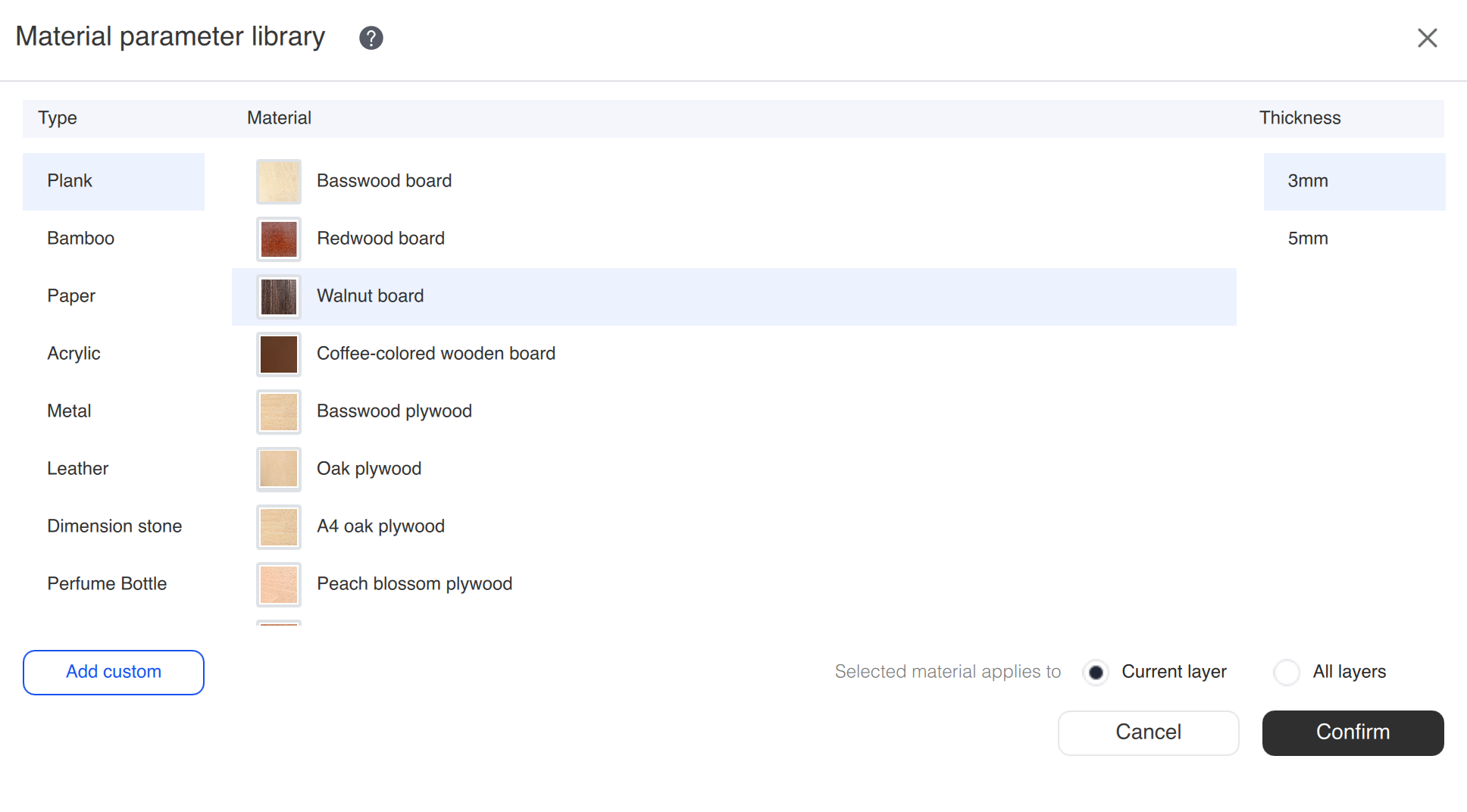

The Material parameter library includes various materials like basswood, acrylic, stone, and others with common thicknesses selectable. Selecting a material will automatically populate the parameters for either a selected layer or all layers, something to be careful with when you have a job with multiple operations.

Unfortunately, the material library doesn’t include photo examples of the impact of changing the parameters, like the Material test in WeCreat MakeIt!. While this isn’t a requirement for a processing software, it means that users will need to run at least one test to dial in engraving, fill, and cut parameters before committing to a larger job.

There are many useful tools in Falcon Design Space, including the Smart Cutout feature to isolate specific parts of photos with a ‘Magic Wand’ functionality. This tool worked well during testing, and when combined with a greyscale or B&W filter it’s a powerful way to quickly prepare a photo for engraving. The typical workflow involves using Smart Cutout to isolate an image, filter to simplify the image and adjust contrast / brightness, and offset to generate a conformal cutline around the part. These tools in Falcon Design Space are incredibly useful to beginners, but more advanced users may be interested in the highly granular controls offered in advanced software like LightBurn.

Engraving / Cutting with the Creality Falcon A1 Pro

The basic process when using the Creality Falcon A1 Pro is simple: set up a job in Falcon Design Space, place a workpiece in the build area and check alignment, and hit ‘Start’. The Falcon A1 Pro can use the integrated Wi-Fi to connect to the software as well as a direct USB connection to a computer. Falcon Design Space turbocharges this process by including a “Make It” button right on the project page, which will immediately open up a new project with laser parameters already populated.

Image credit: Tom's Hardware

Image credit: Tom's Hardware

The 20W diode laser creates sharp and defined lines during line engraving moves, as well as clean and deep features during fill engrave moves. The gantry moves the toolhead smoothly during large travel moves without stuttering or skipping, resulting in clean contours and even engravings. The default cutting speed for 3mm plywood is set to 550 mm/min, and the fill engraving speed is set to 6000 mm/min.

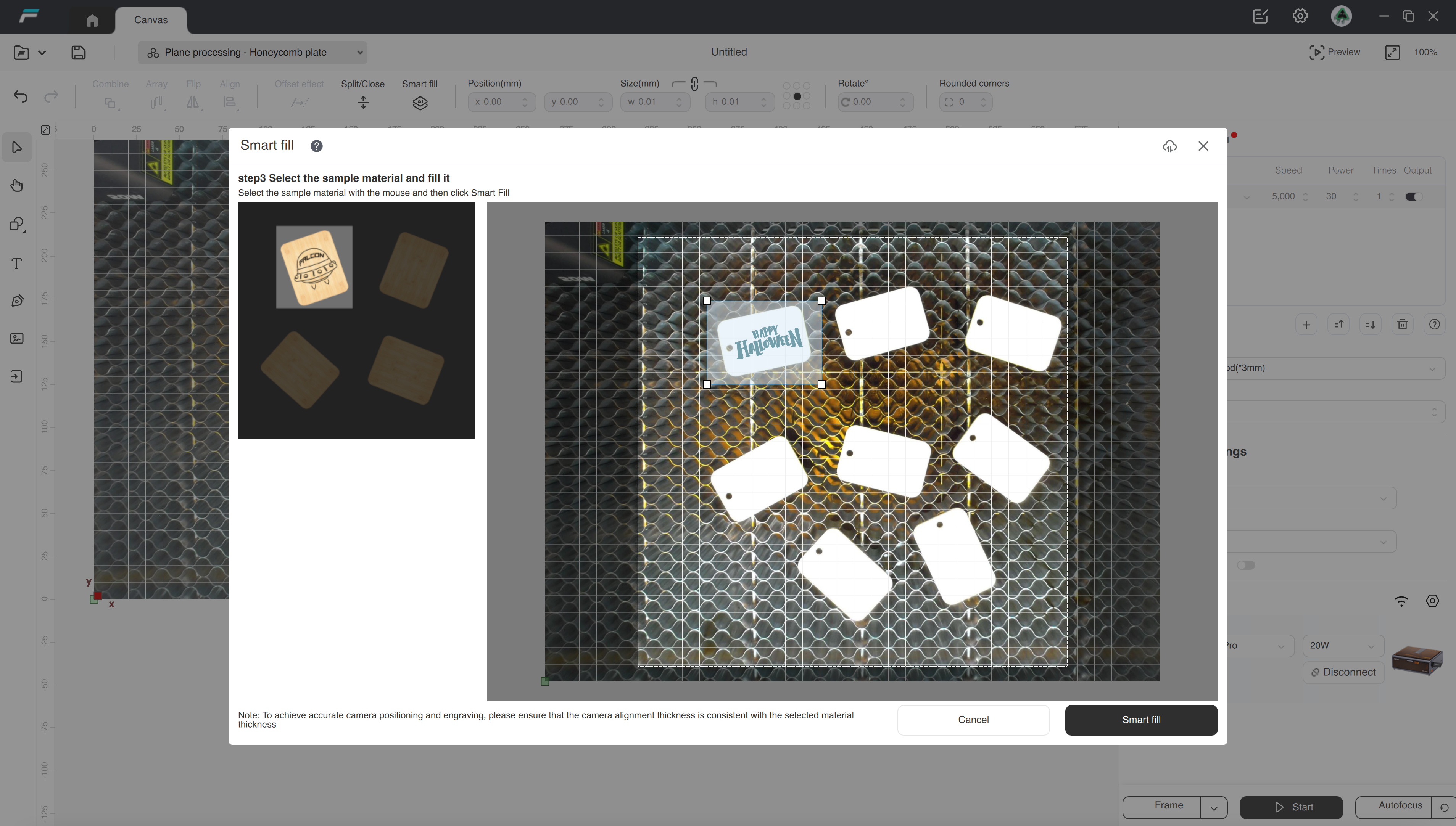

Falcon Design Space also includes a “Smart Fill” tool which will take a selected graphic and automatically copy it across multiple parts on a build. This is an incredibly useful tool if you are making multiple parts in a single build that have the same image. Using one of the included projects, I loaded and oriented a “Happy Halloween” graphic and duplicated it across 7 other parts. The tool worked without intervention and the graphic was automatically rotated on each of the tags.

The job took 16 minutes and 42 seconds using the default speed and power settings for 3mm basswood plywood. I placed one of the tags in the center of the workspace so the automatic focusing laser could be used to set the height, and this worked for all the other tags. This tool is also present in the xTool Creative Space software used by the xTool M1 laser engraver and other lasers that are aimed at small businesses and entrepreneurs, which helps to create a complete solution for business owners interested in maximizing the efficiency of their investment.

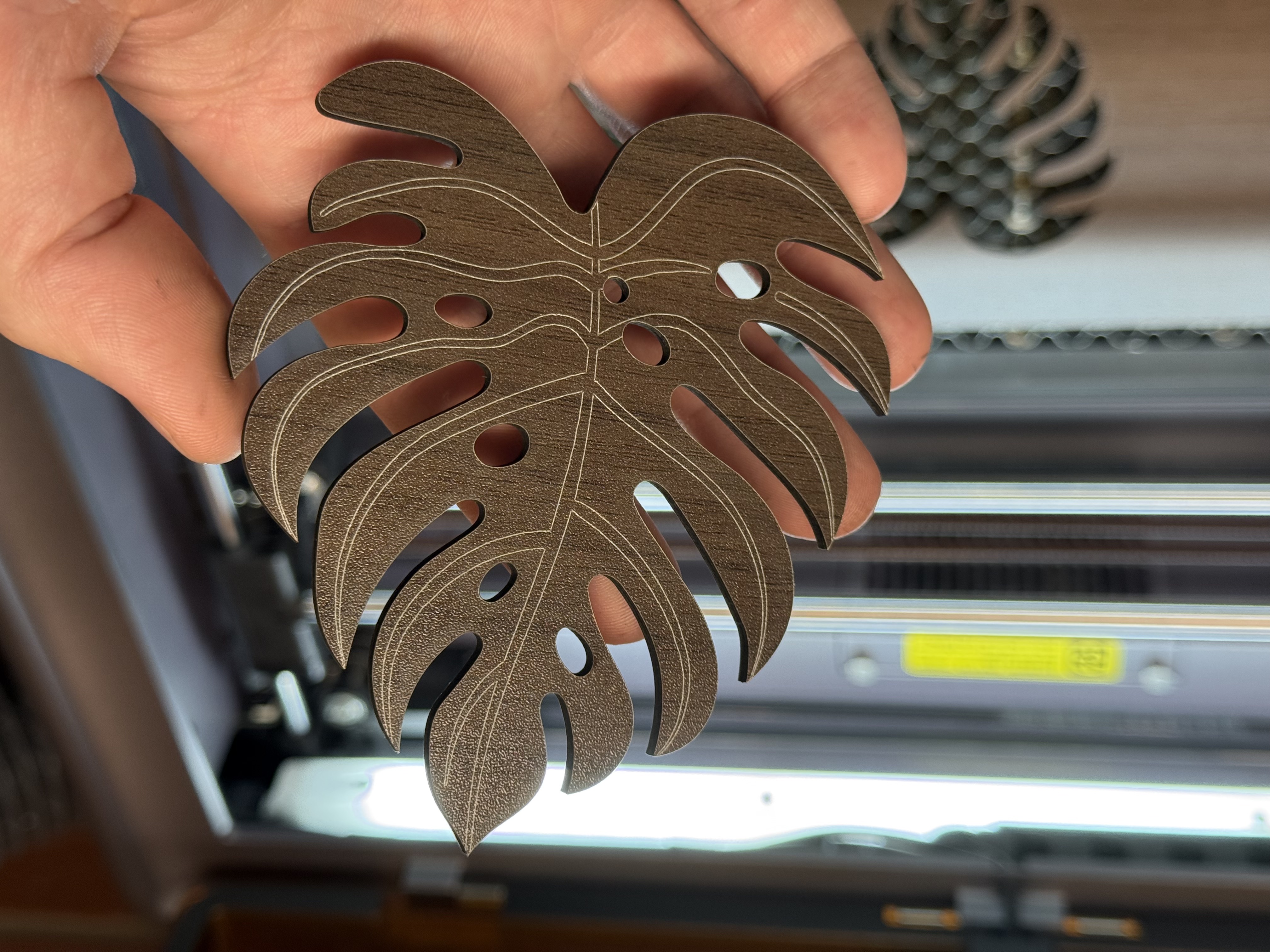

The diode laser is more than capable of cutting through the Creality-provided 3mm walnut plywood quickly, processing a pair of monstera leaf coasters in just over 5 minutes. The organic engrave lines in the center are smooth and precise thanks to the fine spot size of the diode laser, with no jitter or areas of low resolution. The raised honeycomb platform prevented any burn marks from appearing on the surface of the coaster, and the underside was also completely free of defects.

Not just for cutting plywood, the Creality Falcon A1 Pro is also advertised as being able to process PU leather, stone, and other materials that you would typically see used with a diode laser. Using the default settings for a slate coaster, this design took 13 minutes and 55 seconds to engrave completely.

Image credit: Tom's Hardware

Image credit: Tom's Hardware

The 20W blue laser easily etched the surface of the stone coaster, and the quality of the engraving was consistent even across the uneven surface of the slate material. The appearance of the engraving can be altered by adjusting the speed and intensity of the laser, something which can be used to make engravings that appear to have multiple colors or layers.

Other materials like dual-layer PU leather patches are also capable of being engraved with the 20W diode laser, and I was satisfied with the overall quality of these engravings. Falcon Design Space contains basic parameters for this material and others, which allowed me to dial in the appearance of the engraving without needing to run multiple tests to figure out the base settings.

Bottom Line

Creality offers the Falcon A1 Pro in a variety of bundles, and the Basic Pack used in this review (which includes the laser and the honeycomb platform) is a solid deal at $949. While it’s not one of the best laser engravers, the Falcon A1 Pro is a solid entry in the sub-$1,000 price point for a prosumer laser engraver. Having a fully enclosed work area with an exhaust is a huge benefit for managing smoke and fumes, and the automatic leveling removes much of the manual work involved with setting up a job.

Optional accessories not covered in this review include a 2W IR laser for engraving metal and a rotary attachment for engraving tumblers, rings, and other cylindrical objects. Creality has also recently launched a larger air purifier for the Falcon that may be worth investigating if you think the smaller unit isn’t going to cut it.

If money isn’t an issue and you’re looking for something with a stronger diode laser, the WeCreat Vision Pro 45W sells for around $2,249 and offers a similar software experience. If you don’t need all the bells and whistles, the smaller WeCreat Vista offers a lower power laser while keeping the enclosure and sub-$800 price point.

Andrew Sink first used a 3D printer in 2012, and has been enthusiastically involved in the 3D printing industry ever since. Having printed everything from a scan of his own brain to a peanut butter and jelly sandwich, he continues to dive ever more deeply into the endless applications of additive technology. He is always working on new experiments, designs, and reviews and sharing his results on Tom's Hardware, YouTube, and more.

-

prollie The display and bracket/mounting plate detaches fully as one part from the machine in 3 seconds. There are two legs sticking into the block that its cable comes out through. Just pull the display towards you until the legs clear the block, flip it over and detach the cable. Or detach the cable first.Reply

The mounting plate is very simple and attached to the display with just two screws. So if you do break those legs, it's very easy to 3D print and replace with a new one. Or make a custom mount to your liking.