Tom's Hardware Verdict

Creality’s K2 Pro Combo 3D printer is a mid-sized, four-color speedster with a lot of polish, but not quite as good as the earlier K2 Plus.

Pros

- +

Four color printing

- +

Impressive speed

- +

Heated chamber

- +

Step-servos on the X and Y axis and the extruder

Cons

- -

Printing TPU is challenging

- -

Long, high-flow hotend requires more purge waste

- -

Cables to CFS are too short to allow installation anywhere but on top of the printer

- -

Expensive

Why you can trust Tom's Hardware

The Creality K2 Pro is the smaller companion to 2024’s massive K2 Plus, which was Creality’s first foray into four-color Core XY 3D printing. We’ve been waiting a long while for the K2 and K2 Pro, which are a more manageable size and price. We first saw the smaller K2s at Rapid TCT this year, but only recently got our hands on one for review.

Creality’s naming system for the K2 lineup is misleading and confusing. The K2 is about the size of a Bambu Lab X1C, but bigger than the first Creality K1, which stuck to the old Ender 3 220 x 220mm build size. The K2 Pro is the size of a K1 Max at 300 x 300 mm, and the K2 Plus is a 350 x 350 mm-sized beast. Confused? So are we.

All that aside, the Creality K2 Pro really shows how far we’ve come since the old Ender 3. Now we expect printers to work out of the box and produce flawless multicolor prints, all without tuning, modding, or going through voluminous test prints with every change of filament. The K2 Pro with its CFS box did just that. It has excellent print quality, even though it produces a lot of purge waste due to its high-flow nozzle. Other than a bit of trouble with TPU, the K2 Pro pleasantly surprised me with a long run of perfect prints and no fails.

The list of features packed into the K2 Pro is impressive. The sturdy die-cast aluminum frame sits on squishy vibration-dampening feet. The machine is fairly quiet with the door closed, and the chamber cooling through the air purifier is good enough in practice to run PLA and PETG without the door open. Chamber heating does take some time to reach its maximum temperature of 60 degrees, but it makes printing ABS and PC (Polycarbonate) a breeze. Dual AI cameras for failure detection and flow compensation, a high flow hotend, step-servos on the X, Y, and extruder, smart auto leveling, which taps only the area to be printed on, and the CFS is the easiest loading filament system on the market.

It retails for $999 as a combo with its four-color CFS and $799 as a standalone. You can also connect up to four CFS units (at $319 each) for 16-color printing. It’s not quite one of the best 3D printers you can buy, but it’s pretty close.

Specifications: Creality K2 Pro

Build Volume | 300 x 300 x 300 mm (11.81 x 11.81 x 11.81 in) |

Material | PLA/PETG/TPU/ABS (up to 300 degrees) |

Extruder Type | Direct drive |

Nozzle | .4mm (Unicorn) |

Build Platform | Single-sided Textured PEI steel flex plate, heated |

Bed Leveling | Automatic |

Filament Runout Sensor | Yes |

Connectivity | LAN, Creality Cloud, USB |

Interface | 4 inch Color touch screen |

Machine Footprint | 445 x 505 x 850 mm (17.5 x 19.8 x 22.5 in) |

Machine Weight | 23.7 kg (~ 52.25 lbs) |

Release Date | August 25, 2025 |

Pricing | $999 (combo) $799 (stand-alone) $319 (CFS) |

Creality K2 Pro Combo: Included in the Box

The Creality K2 Pro Combo comes with everything you need to get your printer set up. You get tools to maintain the printer, side cutters, a plastic scraper, and a USB stick. There’s also a sample spool of white Creality Hyper PLA to start your printing journey.

You also get a paper copy of the quick installation guide, with QR codes to the Creality Wiki and the Creality Cloud app.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Design of the Creality K2 Pro

The Creality K2 Pro Combo is built like a tank. Its matte-finished die-cast aluminum frame is solid, and the printer by itself tips the scales at over 50 lbs. The glass door and lid with acrylic side panels allow for good viewing of the print area. The interior is well lit, and the print-monitoring camera provides an excellent view of the action, which can be set to run in full screen from the device tab. The primary camera can also create good-quality time-lapse videos, which is nice, while the second camera focuses on the nozzle for flow adjustment and problem detection. Unfortunately, there is no access to the video of the nozzle camera.

Chamber cooling is provided by a rear-mounted exhaust fan with filtration and a chamber fan mounted near the top rear of the printer. When printing lower-temperature filaments, the chamber fan will kick on whenever the chamber reaches 35 °C. The filtration fan runs continuously. There is a large side-mounted fan for part cooling, and a blower fan mounted on the rear of the tool head. The cooling is good enough to run the printer with the door closed for PLA and PETG, which is a personal pet peeve of mine.

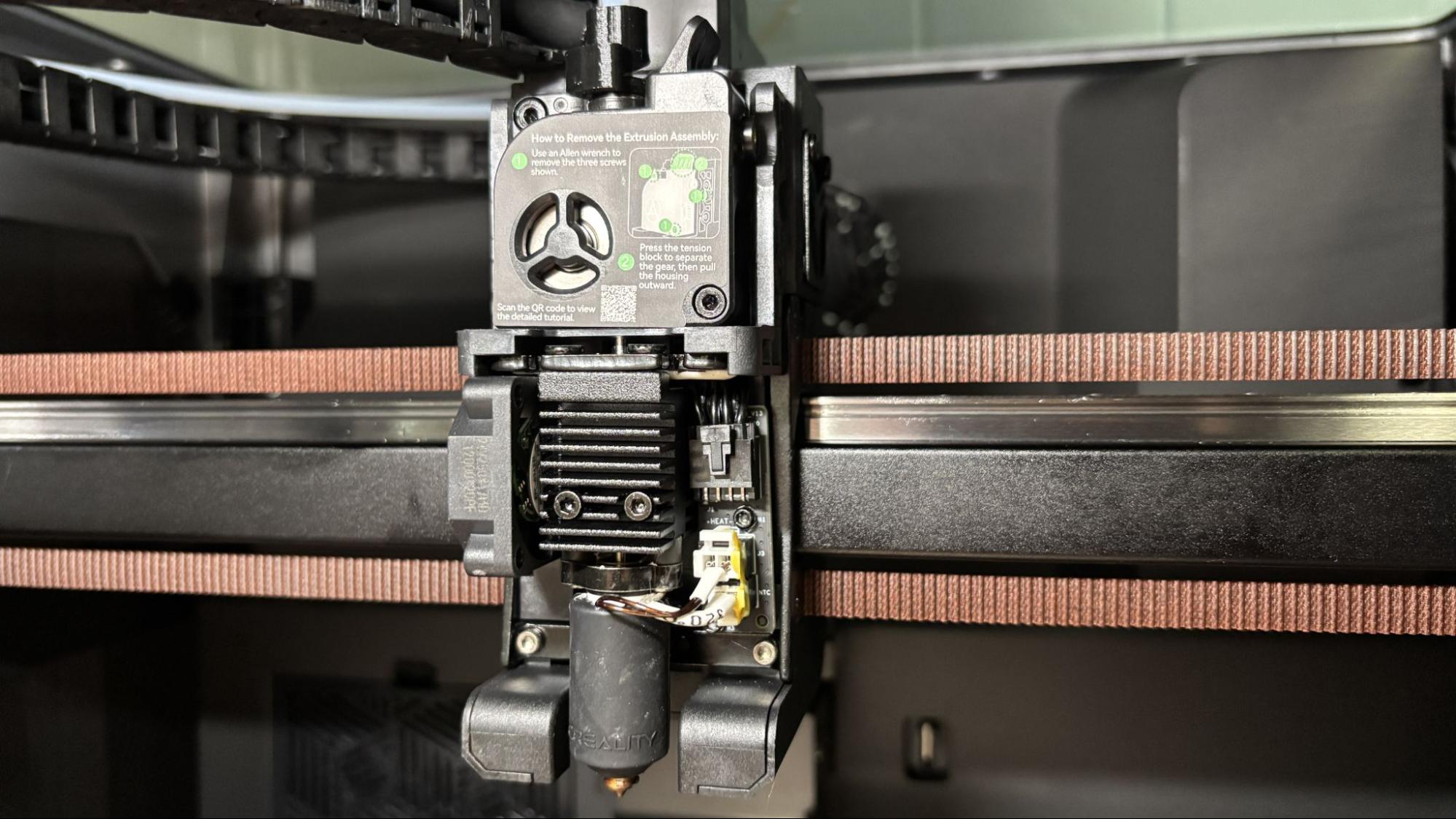

The Core XY motion system is driven by step-servo motors on the X and Y axis, running on a linear rail on the X axis and linear rods on the Y axis. Unlike the usual stepper motors, which are designed to move a certain distance on command, step-servo motors provide feedback on how far they actually move. This allows for greater movement precision and alerts the printer to any problems.

The Z axis is driven by a single stepper motor belted to two lead screws, with the bed riding on four linear rods.

The spring steel build plate is single-sided with a textured PEI coating that was nice and sticky from the start. The bed heats up quickly, and the smart-auto leveling only requires the nozzle to tap the area occupied by the print.

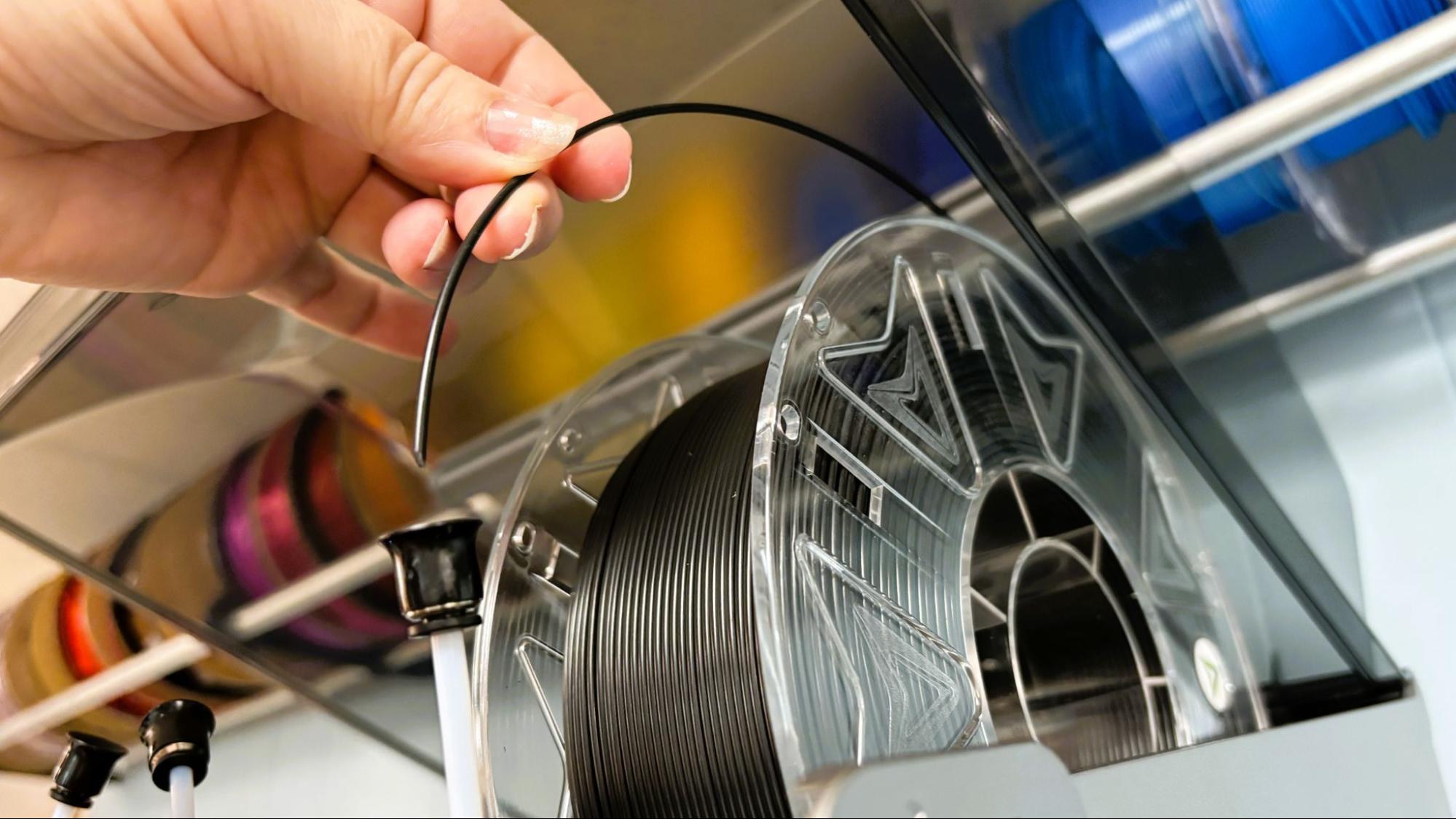

The Creality CFS is a well-heeled multicolor system that compares favorably to the Bambu Lab AMS. At this time, it cannot dry filament, but it may be the easiest to load a multicolor system available. The PTFE (Polytetrafluoroethylene) guide tubes make loading effortless, and the filament retracts to within a few inches of the CFS when done printing, making it super easy to swap spools. Creality is still providing extremely short cables to attach the CFS to the printer, which means it can only be set on top of the printer, not next to it on the table. This means powering down and unhooking the cables if you have to take off the lid to get at the tool head.

Thankfully, Creality is still using the same “unicorn” style high flow nozzle for the entire K2 line up. It’s also compatible with the Creality Hi, so hopefully they’ve settled on one size going forward for now.

Like the K2 Plus, the K2 Pro has a single filament spool you can bolt to the side if you didn’t opt for the CFS or have a spool that doesn’t fit inside the box. There is an RFID tag reader on the side of the machine, so it can still read Creality branded filament.

The Core XY motion system can hit acceleration rates of 20,000 mm/s², which is less than the beefy K2 Plus. Rubber feet are included, which help dampen vibrations, though it still jiggles like crazy on some fast prints.

It has the same screen and easy to use menu system as the other core XY printers, with helpful thumbnails supplied by Creality Slicer.

The Creality Filament System (CFS) looks a lot like a Bambu Lab Automatic Material System (AMS), and operates largely the same way. I found it to be much easier to load as there are no stiff buttons to release the feed mechanism tension. It has a similar compartment for desiccant packs to keep filament dry, and a large display on the front of the CFS tells you what the temperature and humidity levels are inside the box. There’s no active heating element in the box, so the temperature fluctuations would only be from sitting on a hot printer.

Assembling the Creality K2 Pro Combo

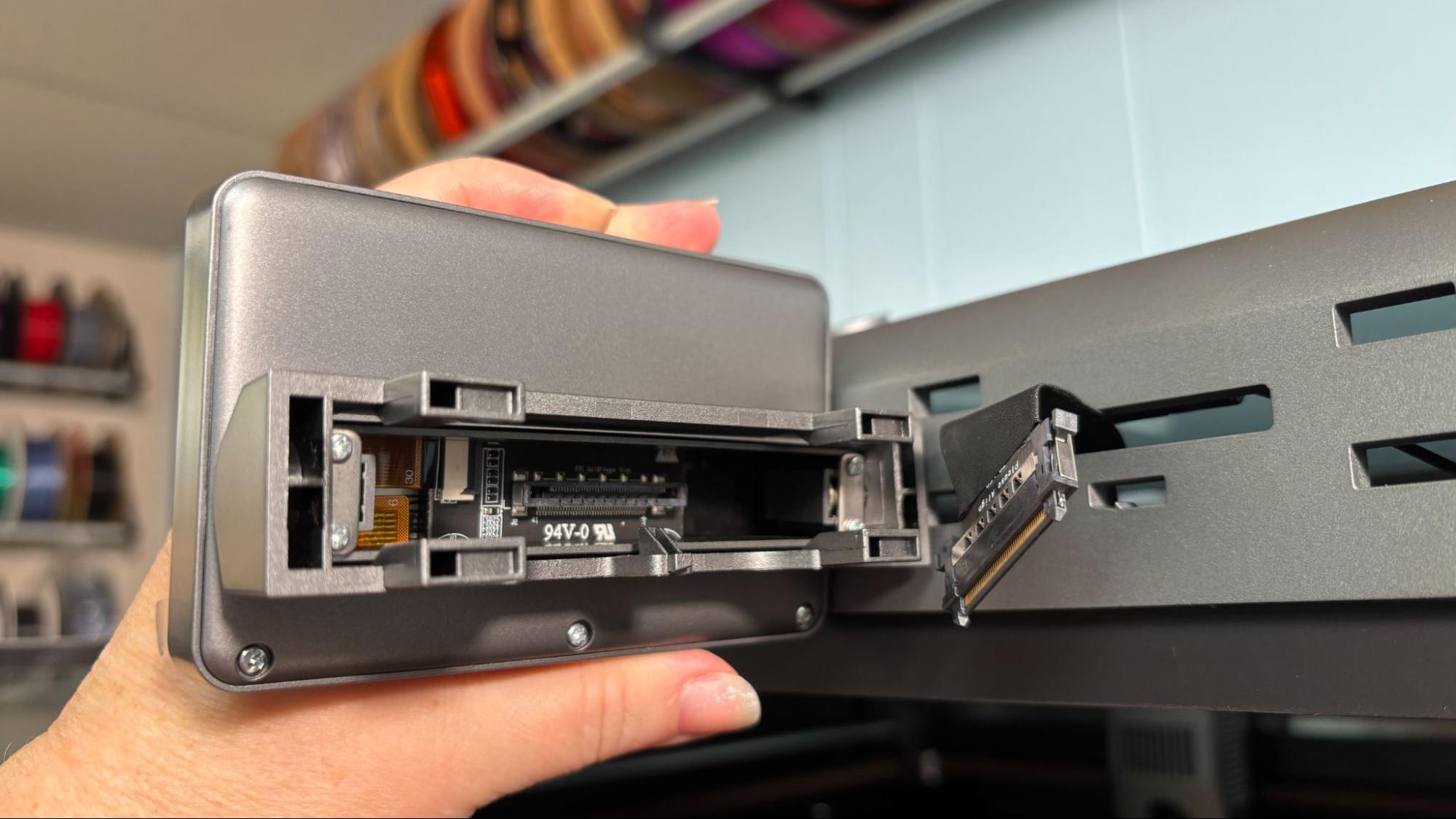

The Creality K2 Pro arrives fully assembled and only needs to be unboxed and unpacked. There are a few well-marked screws to release the CFS and the bed, some foam to remove and some zip ties to cut. The touch screen slots in without tools after the ribbon cable is attached.

There is a single spool holder that attaches with 2 m3 screws, and the CFS buffer attaches to the rear with two m3 screws. That just leaves the CFS cables and Bowden tube for completion.

Leveling the Creality K2 Pro Combo

The Creality K2 Pro Combo has a smart auto leveling program that uses the nozzle to tap the bed only in the area the current print will be using. Full bed auto leveling is part of the initial calibration and can be refreshed from the calibration options if needed.

Loading Filament on the Creality K2 Pro Combo

Loading and unloading filament using the CFS is super simple. Insert the filament into the PTFE guide tube and the CFS will take it from there. Once the printer is done with the filament it retracts to a point where it is easily removed. Creality filament will be automatically detected and show up on the printer’s screen and in the slicer once you hit the auto mapping option. Other brands of filament will require you to enter the filament type and color from the printer’s touch screen.

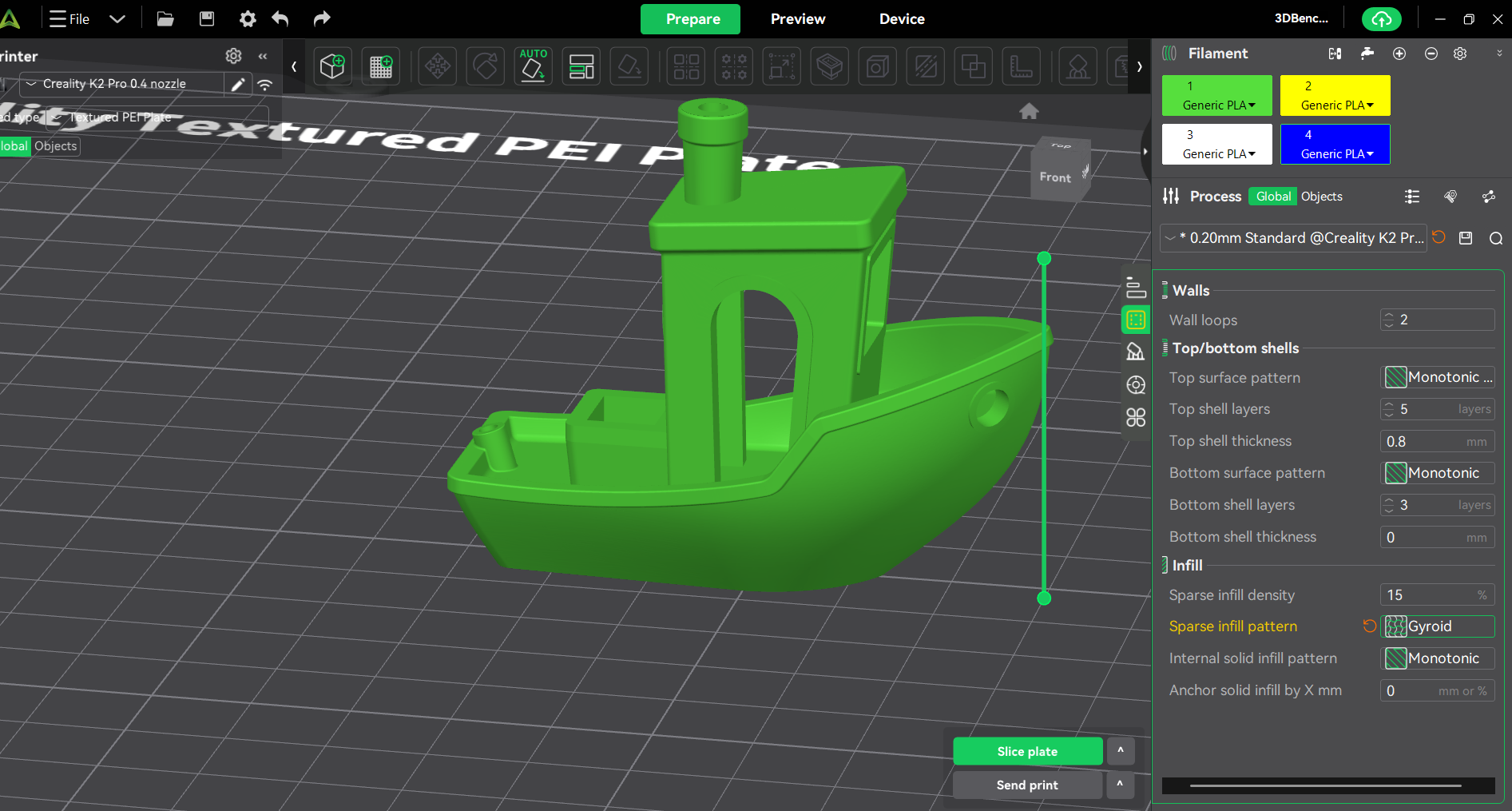

Preparing Files / Software for Creality K2 Pro Combo

I downloaded Creality Print 6.3 from Creality.com. It is a custom program based on Orca Slicer and Cura. The slicer is fairly intuitive, but not exactly beginner-friendly. Thankfully, the default settings are pretty good as they are, so you don’t need to poke around too much.

Creality Print connects to Creality Cloud for both downloading models from Creality’s file-sharing site and uploading to your printer. If you don’t like the Cloud, you can avoid it by dropping STL files from your computer into the slicer and transferring them to the printer via LAN or using a USB stick.

The interface has a LOT going on, but once you find all the buttons, it’s as good as Bambu or OrcaSlicer. The “device tab” is a simplified Klipper screen that shows your printer’s file storage, temperatures, motion system, and camera. To access the full Fluidd screen (Klipper UI), type your machine’s IP address followed by :4408.

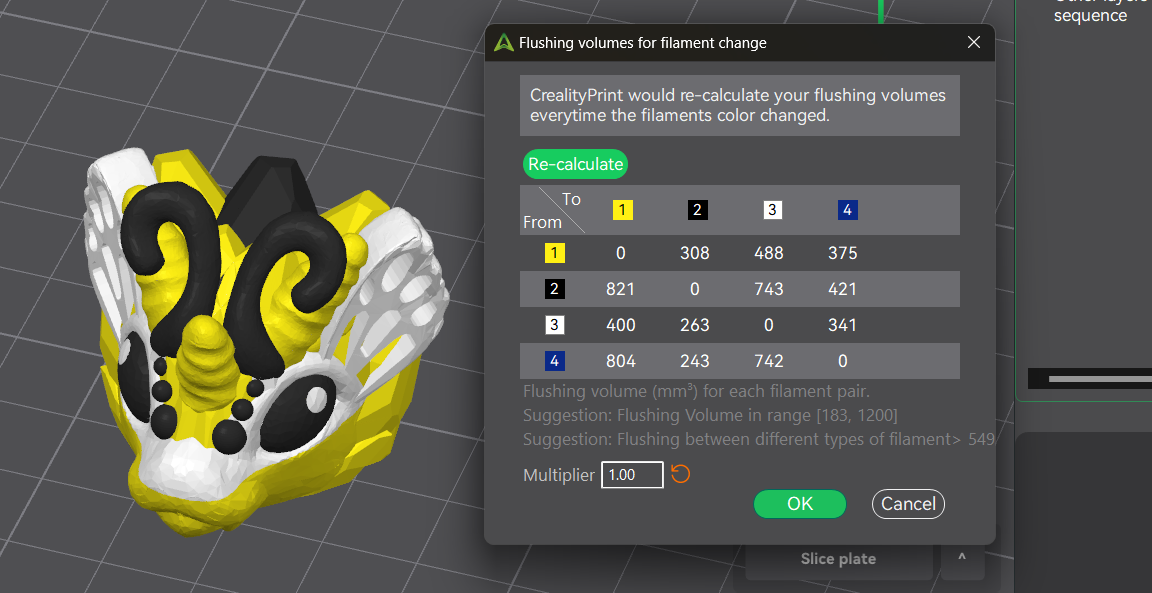

Creality Slicer now allows you to tweak your purge volumes by color as well as the overall “multiplier,” which is a welcome change. You’ll need to use caution with tuning light colored filaments, as they still require a hefty purge amount due to the size of the high-flow nozzle.

Printing on the Creality K2 Pro Combo

The Creality K2 Pro Combo comes with a partial spool of white Hyper PLA. If you want more colors and materials, you should check out our guide to the best filaments for 3D printing for recommendations.

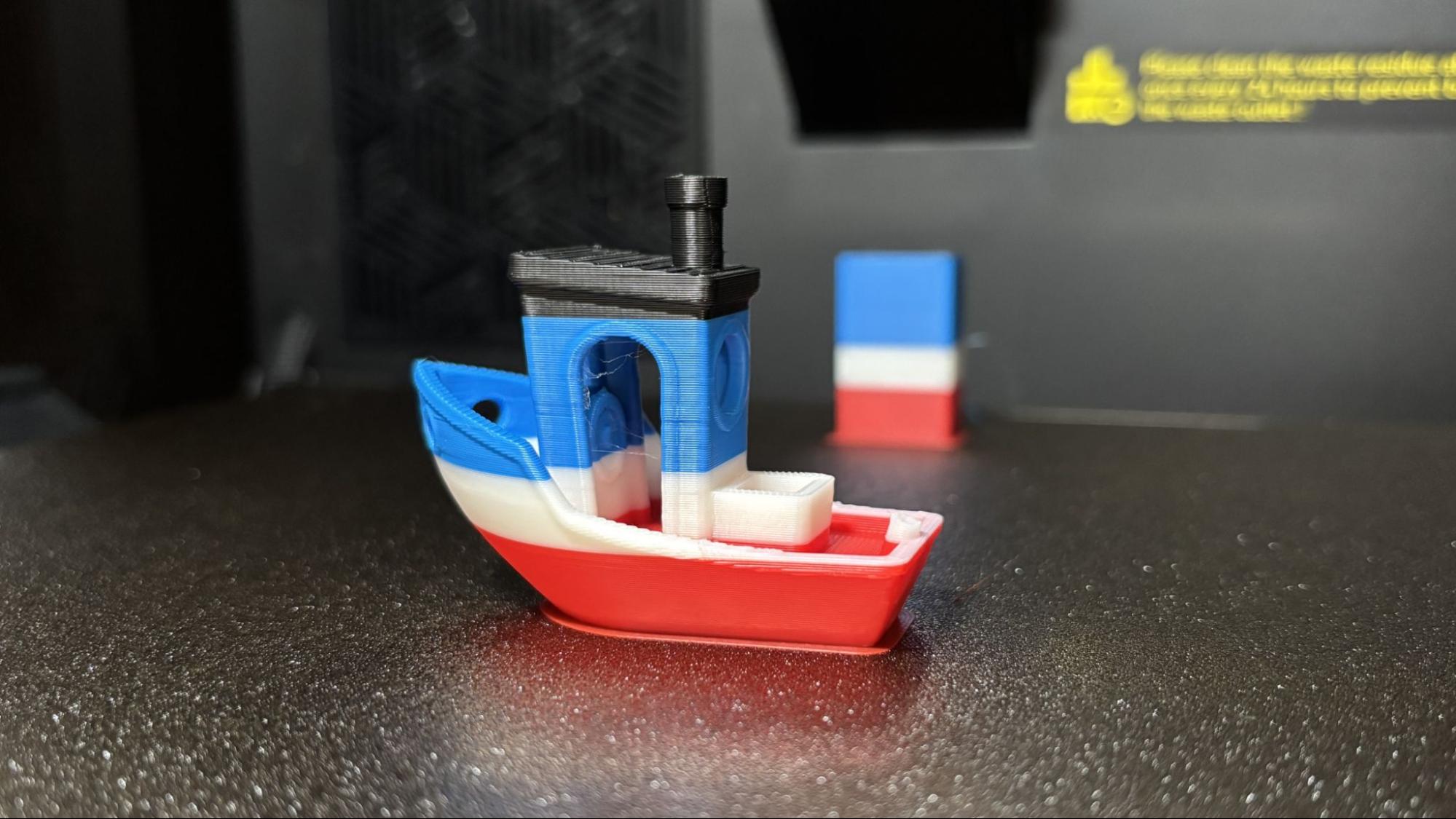

For the first print, I ran the printer’s presliced four-color Benchy, which printed in 35 minutes using Creality’s Hyper PLA. The Benchy looks fantastic, as you’d expect from a presliced file.

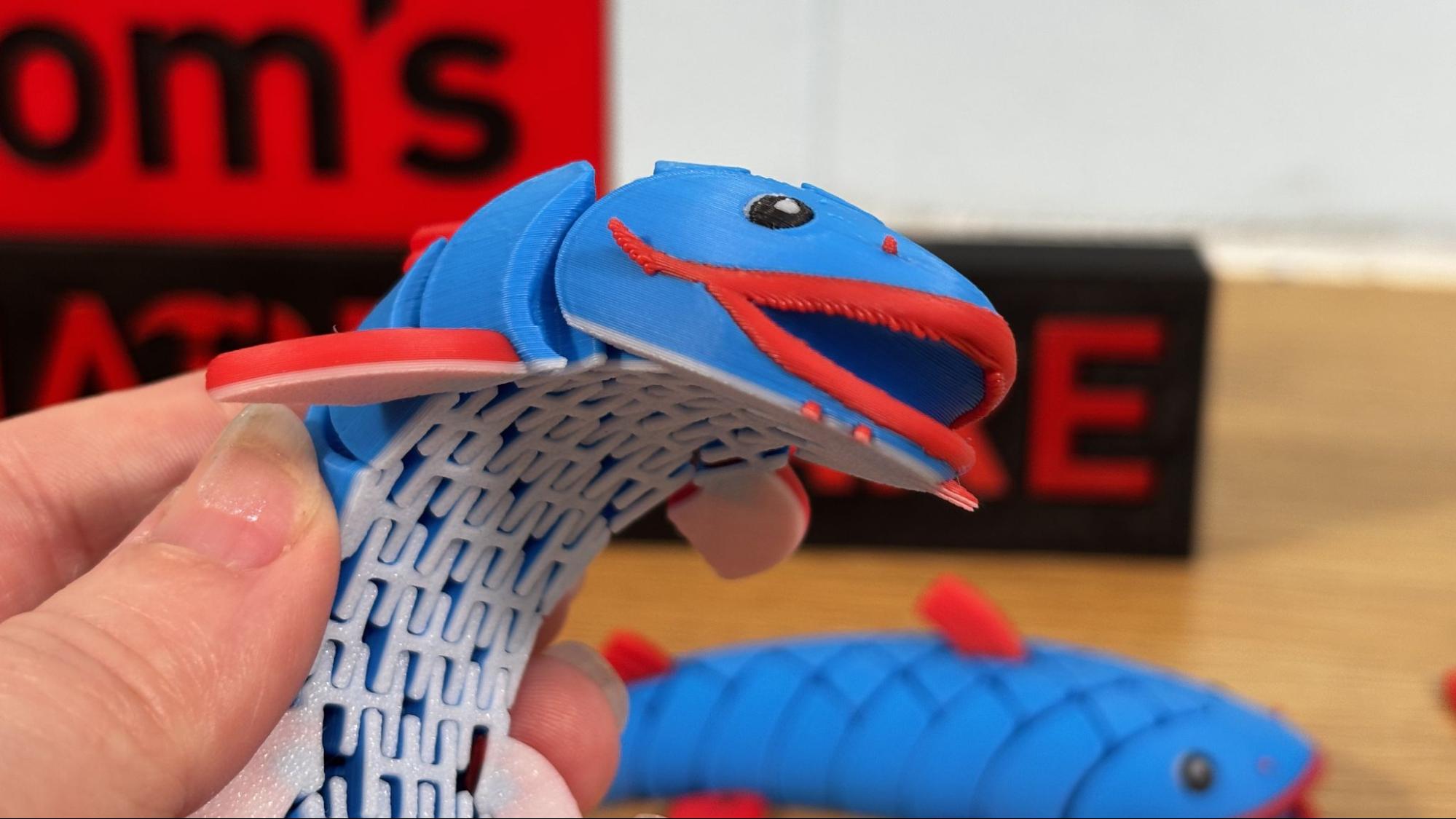

I decided to slice something myself in the same colors. The stock purge volumes and the super long melt zone in the unicorn hotend produce a ton of purge waste, but the results on this four-color Flexi catfish are really, really nice. This file is from FilliFuu on Makerworld. It showed excellent color transition with zero bleed-through going from dark to light colors. A plate of four catfish took 13 and a half hours to print using a .16 layer height and average print speed of 180 mm/s. The result is a very nice print with a nice matte finish using four colors of Creality Hyper PLA.

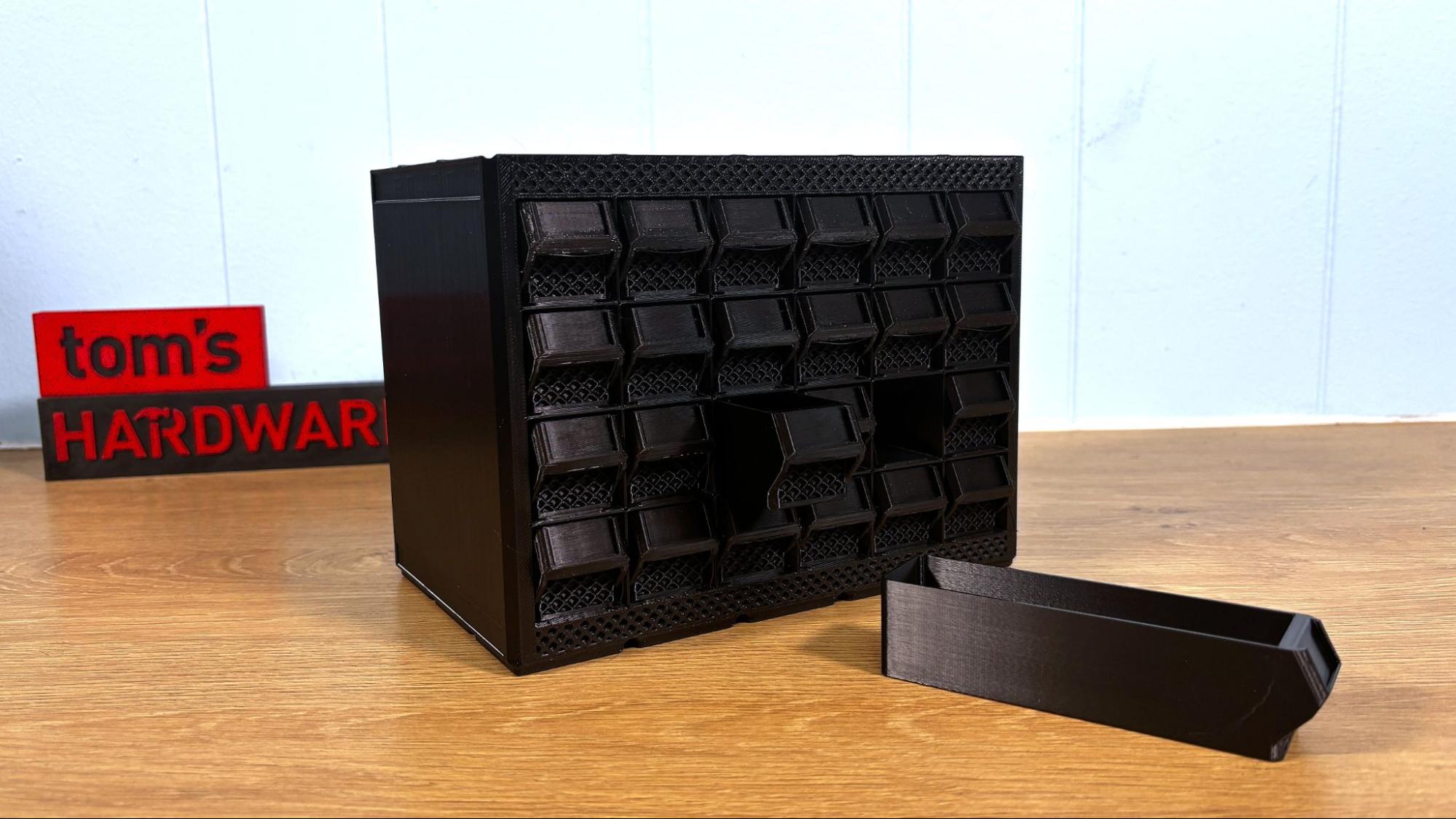

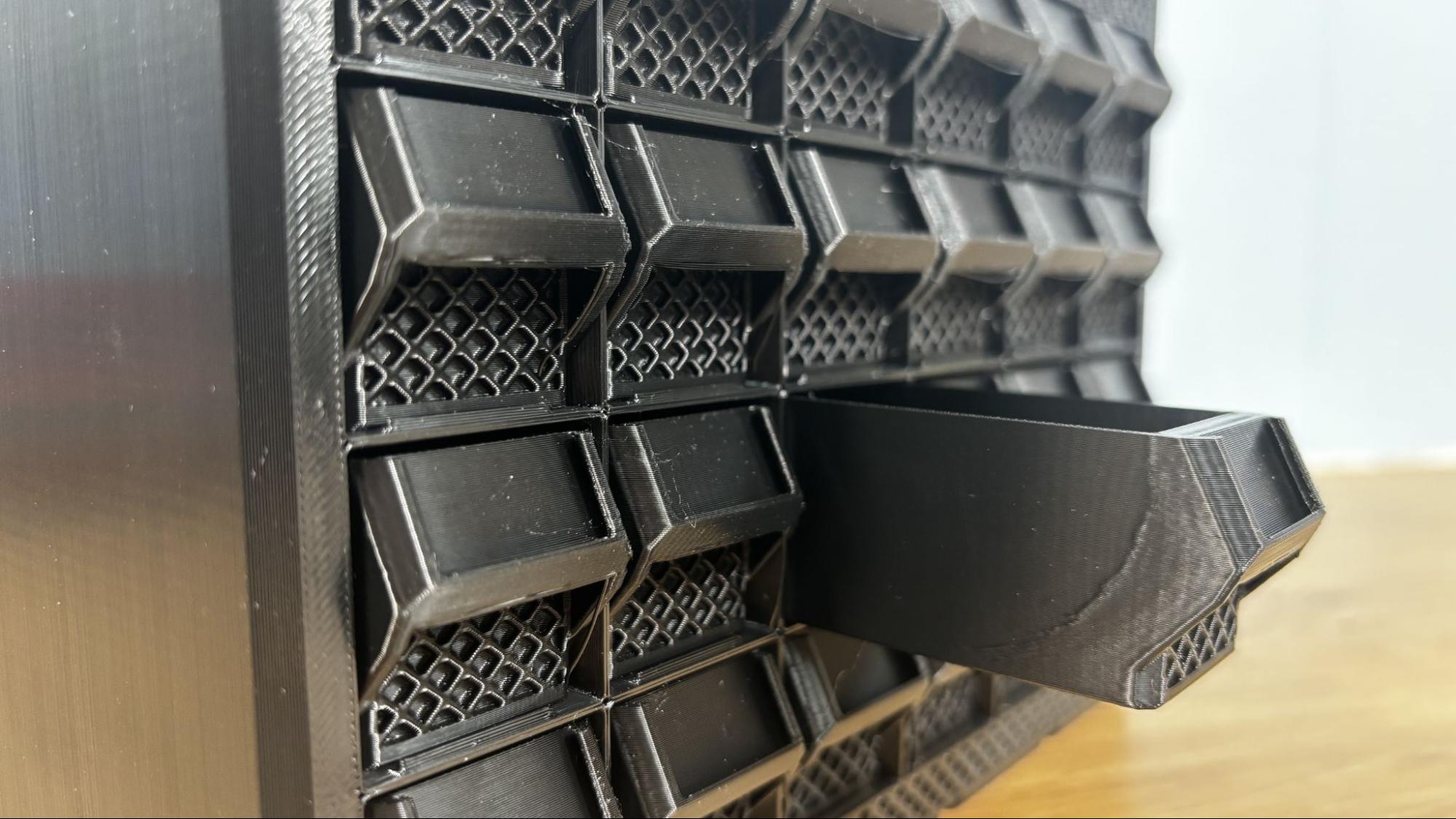

For PETG, I printed something a bit more involved: a kilo’s worth of Gridfinity storage for hardware. It took three build plates and 28 hours to print. The print came out very nice, with just a little stringing, using a .2mm layer height and average print speed of 170 mm/s using Prusa Jet Black PETG.

The K2 Pro Combo can print TPU (allegedly, but I have yet to see proof of it. I tried multiple TPU filaments, from hard TPU for AMS from Bambu Lab, to my favorite rainbow TPUs from Inland. The hard TPU print did finish, but the result was an under-extruded mess. Bumping up the flow in the slicer made no difference, nor did running from the external spool holder or directly to the tool head.

(An internet search found that others also have difficulty with TPU on Creality K2 Pro, and some found success, but only if you’re willing to replace a spring inside the toolhead.)

Thankfully, with the ability to run 300 °C on the nozzle, 110 °C on the bed, and 60 °C in the chamber, the Creality K2 Pro Combo can print the majority of the more technical filaments out there. It prints ABS well, but my favorite, though slightly persnickety, technical filament is Polycarbonate (PC). The CFS cannot dry filament, but it can prevent further moisture absorption if you keep it shut with fresh desiccant packets in place. It did an excellent job printing dry Polymaker Poly Max PC with no warping and excellent bed adhesion.

One of many prints I did in PC is a handy little Utility Blade Scraper. Using a .2 mm layer height and an average speed of 100 mm/s, the scraper took a little under 30 minutes to print, and it is both a pretty and functional print.

Bottom Line

The Creality K2 Pro Combo is a send-it-and-forget-it printer for anything other than TPU. It has Core XY speed and produces excellent quality prints. It’s easy to load, levels perfectly, and features dual AI cameras. Retailing for $999, the K2 Pro Combo is not cheap, but it makes up for it with its extra 300 mm³ of “helmet class” build volume.

Ultimately, the K2 Pro Combo lands in a sweet spot: larger and more refined than entry-level machines, but easier to live with than the heavyweight K2 Plus. It’s not a revolution, but it’s Creality’s most polished and capable Core XY to date.

Competition among Core XY printers is getting fierce. If you want more bang for your buck, there’s always the smaller 250 x 250 x 250 mm Anycubic Kobra S1 Combo on sale for $459, or the Bambu Lab P1S Combo, which has been marked down to $549 on the anticipation of the P2S launch in the US. If you want an even bigger color Core XY, check out the Bambu Lab H2S with a 340 x 320 x 340 mm print volume for $1,499.

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing. Denise has been crafting with PCs since she discovered Print Shop had clip art on her Apple IIe. She loves reviewing 3D printers because she can mix all her passions: printing, photography, and writing.