Tom's Hardware Verdict

The Bambu Lab H2C solves the plastic waste problem with a massive feat of overengineering, called the Vortek Hotend Changer. It swaps color twice as fast as other Bambu Lab printers, but not quite at the blinding speed of a full tool changer. Like its H2 siblings, this is a premium “manufacturing hub” 3D printer with a large build volume and the ability to be fitted with a laser and cutter. It's a beautiful machine that’s easy to use.

Pros

- +

Vortek hotend changer saves material

- +

Larger build volume

- +

Enclosure for high-temperature printing

- +

Prints PLA with the door closed

- +

Perfect auto bed leveling

- +

Backwards compatible with current AMS

Cons

- -

Expensive

- -

Handles TPU strangely

- -

Proprietary replacement parts

- -

All the extras are a lot extra

Why you can trust Tom's Hardware

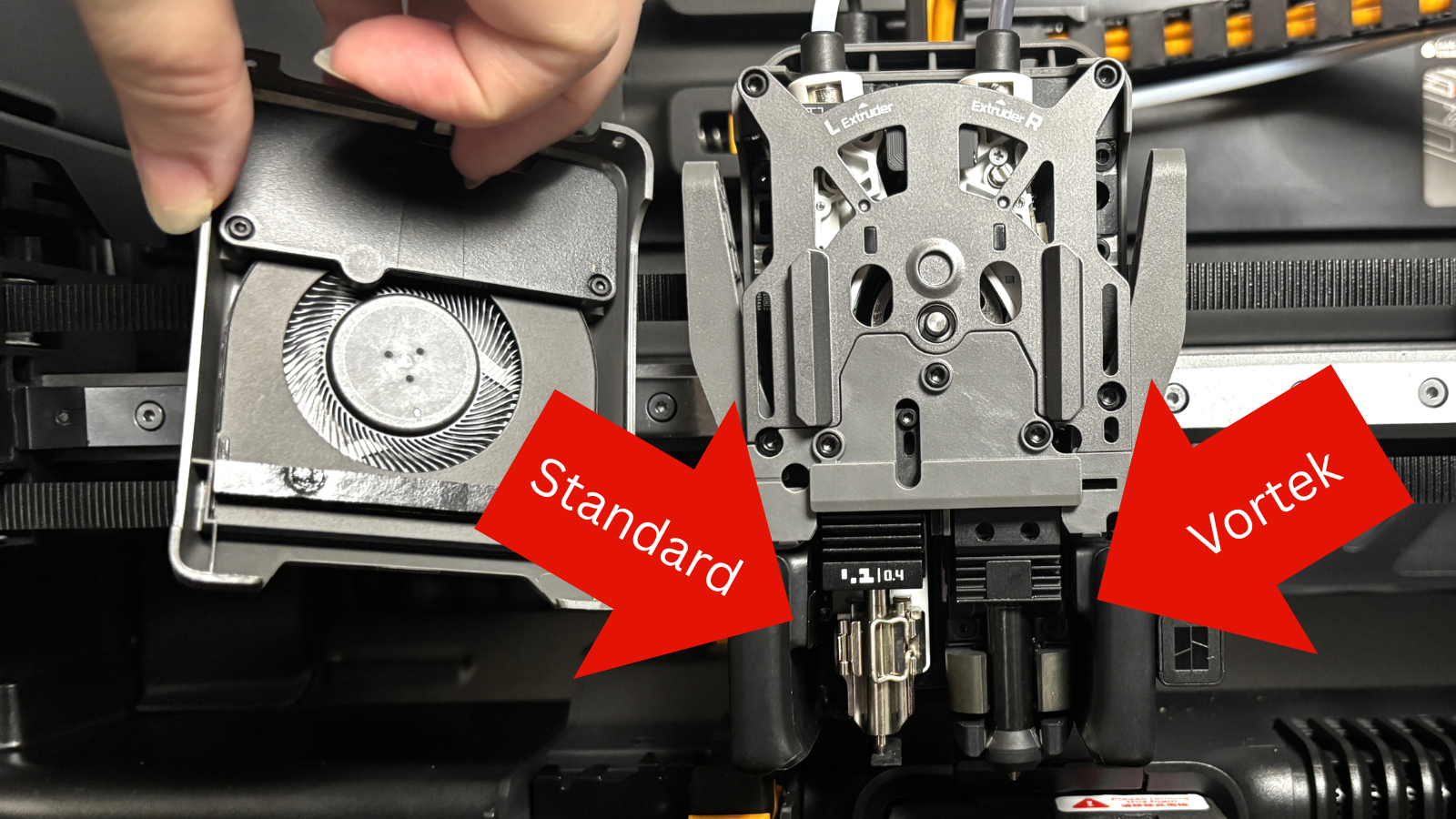

The Bambu Lab H2C is the latest machine to tackle the frustrating problem of filament waste when printing in multicolor. The new Vortek system eliminates waste in a novel way, by assigning each color (or material) its own nozzle/hotend. However, it is not quite what we expect in a true tool changer, as each nozzle still shares one tool head and one AMS in the standard configuration. This does the job of eliminating nearly all the wasted filament left behind when your printer switches color, but it is not as quick at making those swaps as the Snapmaker U1 or the Prusa Research XL.

But we can’t overlook that when compared to other Bambu Lab AMS printers, the H2C is twice as fast. Not spending time purging seriously speeds up the process. In our testing, the H2C took a nearly 24-hour, five-color print from the H2D and slashed the print time down to less than 12 hours.

Normally, when a Bambu Lab 3D printer (with an AMS) needs to swap colors, it will cut the filament off inside the tool head, retract what it can back onto the spool, then push the old color out the nozzle in the form of “poop.” For several years, this spoiled filament has been brushed aside as the cost of doing color 3D printing. The amount of poop produced can be toned down, but not avoided. The only serious solution to the filament waste problem is tool changers, which give each spool of filament its own dedicated tool head. Since the filament doesn’t need to be removed from the nozzle, the only waste is a smallish amount needed to prime the flow. The Snapmaker U1 and the Prusa XL are true tool changers, which give each spool its own tool head with nozzle and extruder for color swaps that take seconds.

The Vortek can hold six nozzles, two more than needed for a standard setup. The “extra” nozzles can be dedicated to a high-temperature filament, which avoids clogs that can happen if you don’t sufficiently clean the nozzle between jobs. Or they can be different sizes, waiting for that time you really need a .2 or .8 nozzle.

The H2C also has a dual nozzle tool head, with the same A1 style left-hand nozzle as the H2C. We assume this was a cost-saving measure – who knows, maybe 2026 will see a machine with a Vortex rack on both sides?

The machine is a flashy technological wonder, but only time will tell if the Vortek system is perhaps TOO complex. It will need many hours of serious testing before we know if hands-free hot-swapping nozzles are worth the cost.

Which brings us to price. The H2C comes with a hefty $2,399 price tag, $400 more than the comparable H2D. Part of the expense is due to the generous 330 x 320 x 325 mm build volume, but the rest is paying for Bambu Lab precision. The H2 lineup is top of the line, with a plethora of sensors, cameras, and premium perks.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The only thing the H2C lacks is the speed of a true tool changer, which is a real shame considering what the competition has been cooking up. It’s still one of my favorite printers of 2025, and definitely one of the best 3D printers we’ve seen.

Specifications: Bambu Lab H2C

Build Volume | 325 x 320 x 320 mm (12.79 x 12.59 x 12.79 inches)* |

Material | PLA/TPU/ABS/PPS (up to 350 degrees) |

Extruder Type | Direct drive |

Nozzle | .4mm proprietary |

Build Platform | PEI textured spring steel sheet (120 degrees) |

Bed Leveling | Automatic, hands free |

Filament Runout Sensor | Yes |

Connectivity | WiFi, LAN, USB Stick |

Interface | 5-Inch Touch Screen |

Machine Footprint | 492 x 514 x 626 mm (19.3 x 20.2 x 24.6 inches) |

Machine Weight | 32.5 KG (71.6 lbs) |

MSRP | $2,399 |

Release Date | November 18, 2025 |

*Build Volume for Dual Nozzle printing is 300 x 320 x 325 mm.

Bambu Lab H2C: Included in the Box

The Bambu Lab H2C comes with everything you need to get your printer set up, as well as a few extra parts. You get tools to maintain the printer, a spare “normal” hotend, and two spare nozzle wiping pads. There’s also a 4-in-1 PTFE adapter in case you buy additional AMS units later.

The printer is preloaded with test models, and practical prints for crafting tools. A razor blade and screws are included to make a DIY scraper. There’s also a paper getting started guide and instructions on how to access the slicer and phone app. The box has a QR code printed on the inside flap that leads to an unpacking video.

Design of the Bambu Lab H2C

The H2C is the 3rd member of the new, massively sized, premium H2 lineup. It is a fully enclosed printer with an aluminum and steel chassis, and sides made of plastic and glass windows. The 5-inch touchpad is identical to the ones on the H2D, H2S, and P2S.

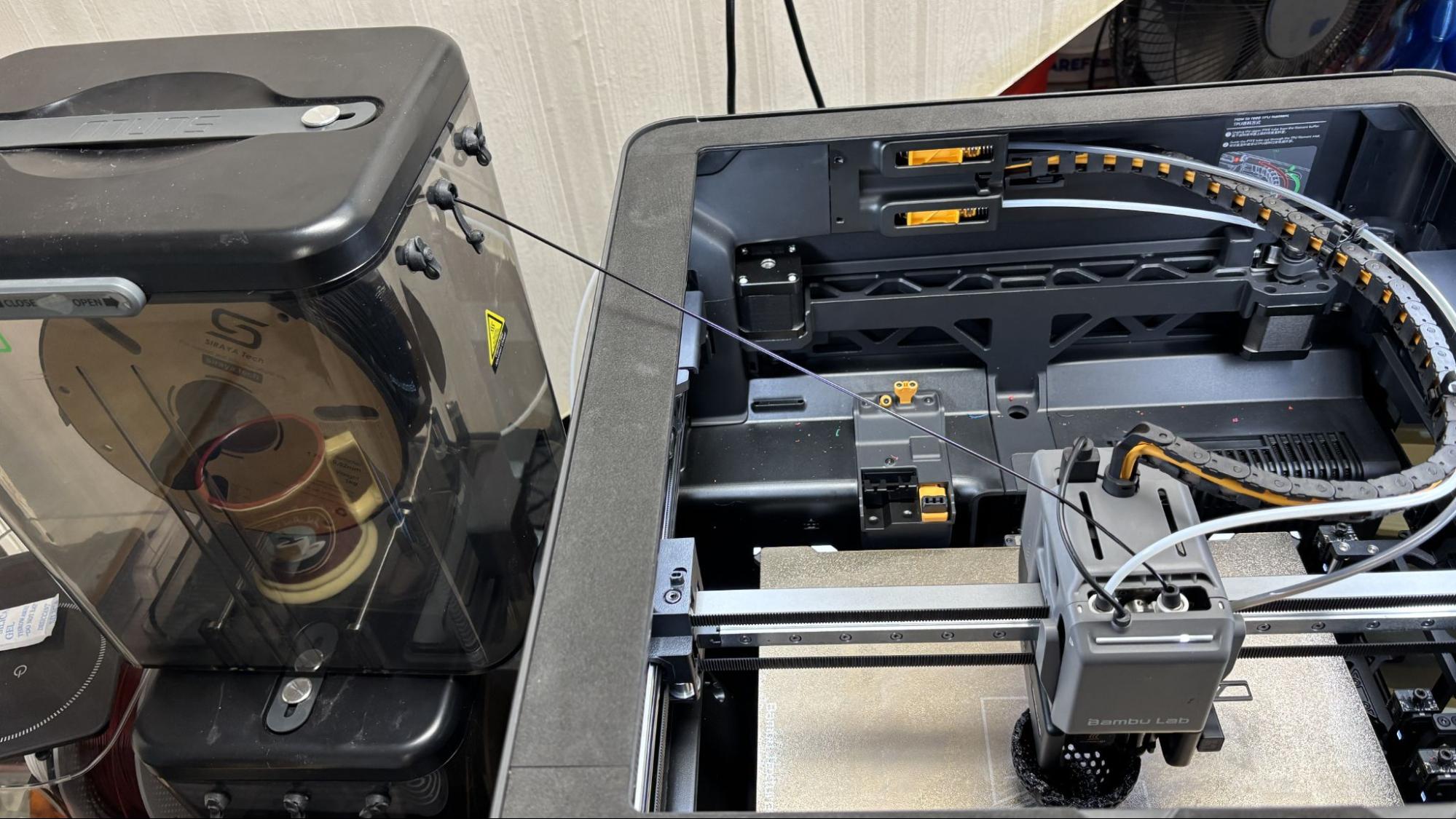

The H2C has many of the same features as the H2D. It comes as either a “stock” non-laser printer or a “laser combo”. Both machines share the same 3D printer capabilities, and the stock version can be upgraded to a laser model if you wish. For this review, we were sent an H2C with no laser and only a four-color AMS 2 Pro.

The Vortek System

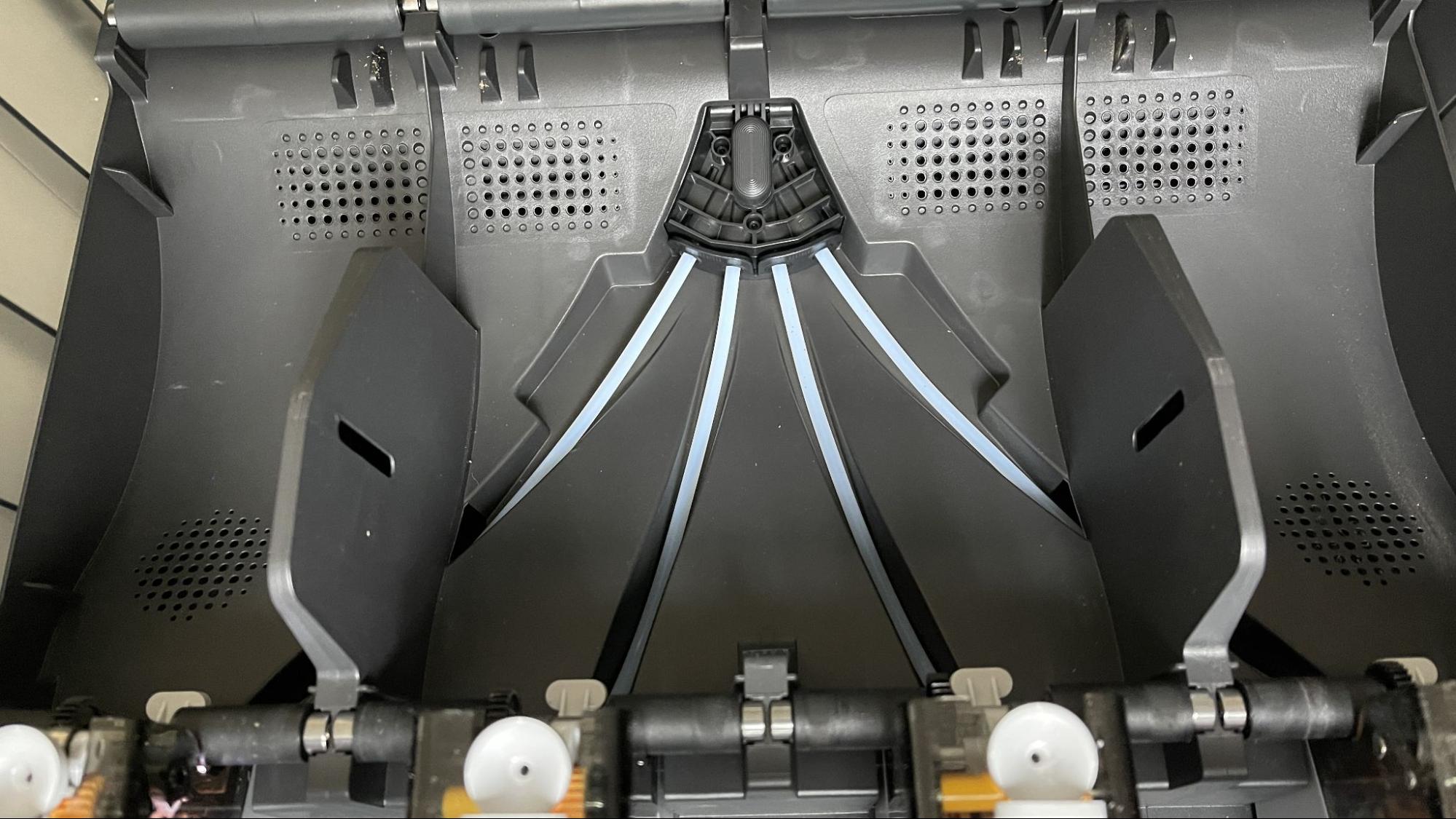

The biggest difference between the H2C and every other 3D printer on the market is the Vortek hotend system, which allows the printer to use 5 to 7 different filaments without waste. Why such an odd number? The H2C has the dual nozzle tool head inspired by the H2D, plus a Vortek rack that holds six nozzles for the right side. When purchased as a H2C Combo, you’ll get one AMS that holds four spools. This automatically gives you access to five spools (one on the left, four on the right). If you hook a second AMS to the right side, you can fill all six Vortek nozzles for seven color, no waste printing. Of course, you can fill all the AMS slots for nine total colors, but two will need to share nozzles and create filament waste.

The H2C can command up to 24 colors if equipped with four standard AMS units and eight single HT AMS units.

Why use Dual Nozzles on the H2C?

The H2C keeps two nozzles on the tool head, just like the H2D. While the H2C has very little filament waste thanks to the Vortek system, the AMS will slow it down. However, the machine is able to more rapidly switch between the left and right nozzles, so there is a speed advantage when you combine these two.

I’m going to assume we still have a “standard” nozzle as a cost saving measure, as the new nozzles are packed with wireless technology and induction heating.

Does the H2C use A1 Nozzles?

Bambu Lab has adopted the A1 style nozzle for the H2 lineup. Compared to the X1C, these nozzles are much easier to change as they are held on with a clasp and magnet. All the wiring remains on the tool head. The H2 nozzles have been improved, so it is not recommended to use old A1 nozzles on any of the H2 models. You can, however, use H2 nozzles on the A1.

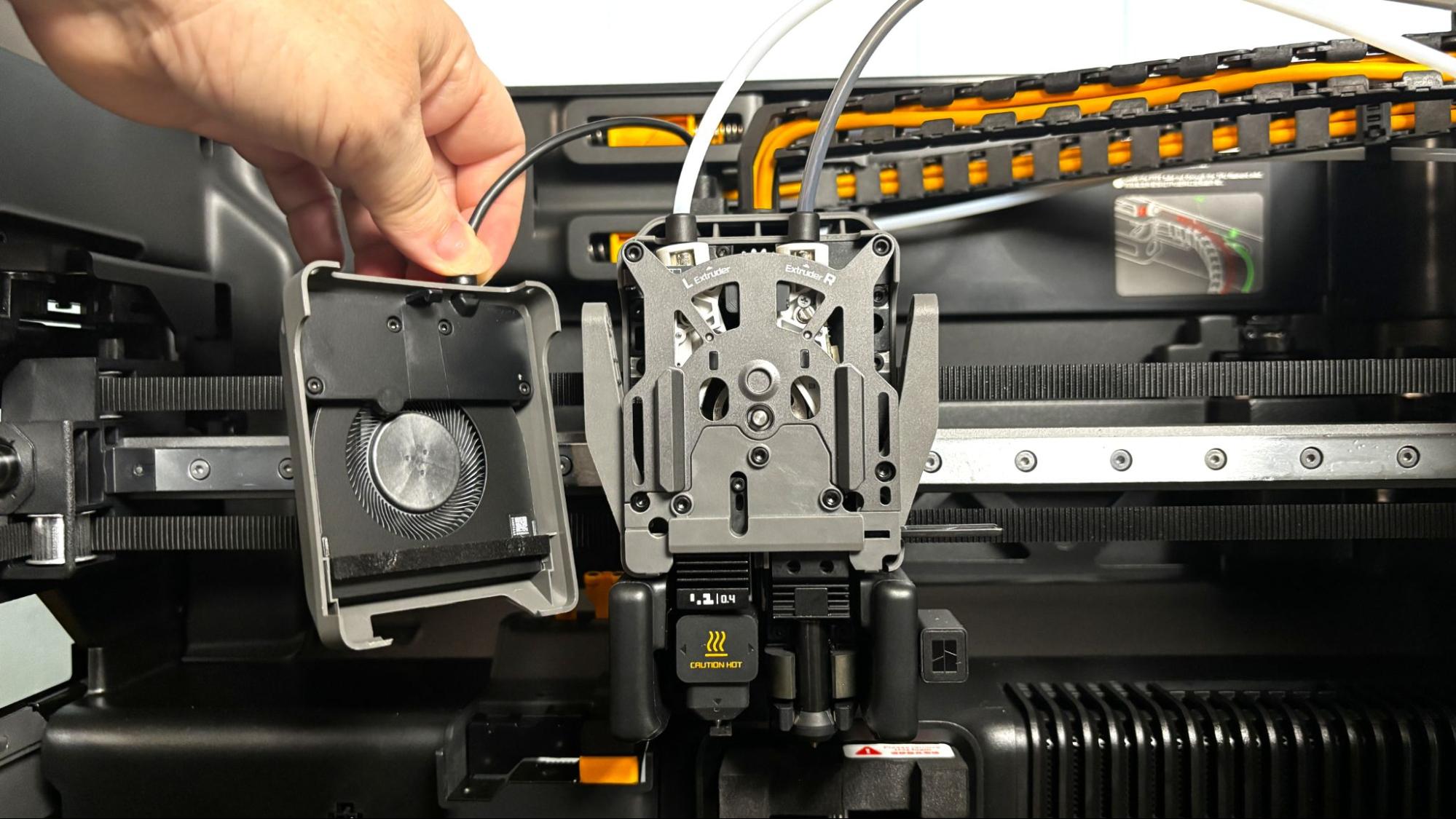

What Nozzle does the Vortek Use?

While the left side uses the standard H2 nozzle, the right side uses a new H2C Induction Hotend. These nozzles are more cylindrical, and contain a contactless interface. They also heat up in 8 seconds, so you’re not waiting around for preheating. The tool head is able to grasp these nozzles without human assistance and one you place them on the rack, the machine does all the swapping on its own. Priced at $39.99 for standard and $69.99 for high flow, these nozzles are $18 to $19 more expensive than regular H2 nozzles.

When not printing, the Vortek nozzles are held magnetically on a rack on the right side of the chamber. There is space for six nozzles, three up and three down.

At the moment the slicer does not support mixing nozzle sizes, so you can not use a .6 and .4 nozzle on the same print.

How Big is the Bambu Lab H2C?

The H2C is a larger machine, with a 330 x 320 x 325 mm total build volume.

Does the Vortek and Dual Nozzles effect the H2C build size?

Yes, the dual nozzles and the Vortek system affect how big you can print. The heated bed is a tad smaller than the H2D and H2S to make room for the nozzle rack.

The left nozzle can use the entire build plate, while the right nozzle can not reach the extreme left side. Build volume for the left nozzle is 325 x 320 x 320 mm, while dual nozzle printing is 300 x 320 x 325 for dual nozzle printing.

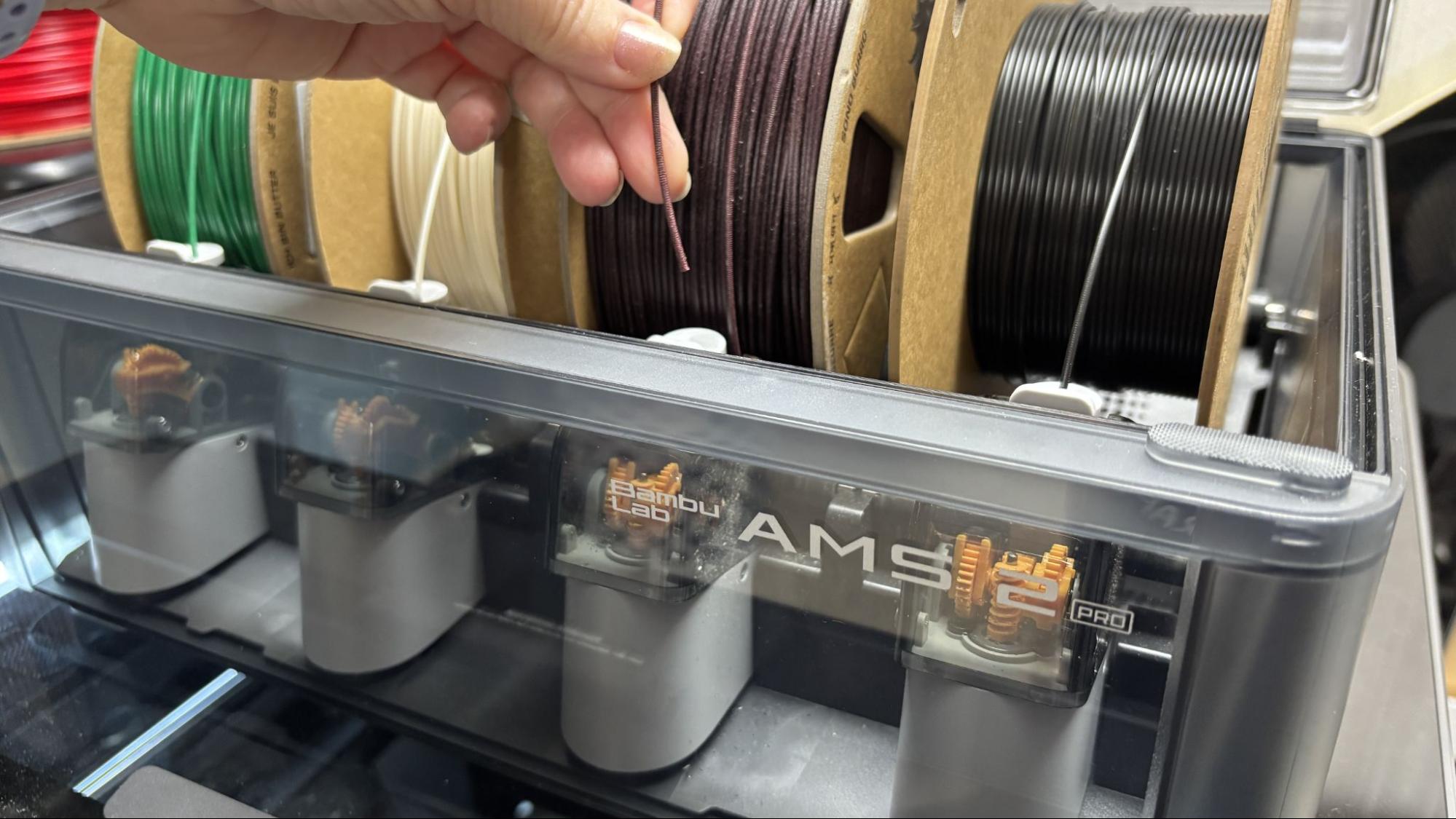

What is the Bambu Lab AMS 2 Pro and AMS HT?

Bambu improved their signature Automatic Material System for the H2D last spring, adding a heater and vents, allowing it to dry your filament. The AMS 2 Pro is now standard. It has a vent that automatically opens during drying cycles to release damp air and can remain closed to maintain a dry environment during storage or printing. The drier does not operate during printing, and instead depends on a tight seal and a packet of desiccant to keep your material cozy. When you set up the drying function, the screen will ask you to tuck the filament ends into the spool’s sides and give you the option of rotating the filament while drying.

The AMS 2 Pro is the four spool model, while the AMS HT is a single spool device. The AMS 2 Pro can heat up to 65C, and the HT can go to 85C. The HT unit also has a bypass allowing you to feed soft TPU or gritty carbon fiber without going through the feeder motor – instead it simply freewheels and allows the tool head to pull the filament through. Oddly enough, the H2C doesn’t allow you to feed TPU to the left-hand nozzle at this time, so I’m a bit flummoxed.

I also didn’t get an AMS HT for the H2C and had to deal with manual loading. I would highly recommend purchasing an AMS HT for your printer if it’s in your budget.

The AMS 2 Pro also winds spools noticeable faster, and keeps the Bowden tubes in the open for easier access should filament break while in the AMS.

How many cameras does the Bambu Lab H2C have?

The H2C has three cameras, plus a fourth for the laser combo.

The main three are all 1920 x 1080: one for live monitoring, one on the nozzle for AI detection, and one on the tool head.

The live preview is for the user and shows up in Bambu Studio on the device page and on your Bambu Handy app. It can also capture timelapses.

The nozzle camera can detect “spaghetti”, air printing, nozzle clumping and when the poop chute is getting clogged.

The tool head camera is for checking accuracy during calibration and reading the codes on the build plates.

The fourth camera is a more detailed, eight megapixel (3264 x 2448p) and comes with the laser combo. It’s optional for the stock printer. This “Birds Eye” camera is used to position materials for cutting.

What kind of Ventilation does the H2C have?

The H2C has automatic vents and fans to do a number of things. An intake vent on the top pops open when it needs cool air for PLA or PETG, or to push air into the filtration system. A rear vent is likewise automatic and can open or close as needed. The H2C can close the vents to retain heat for high-temperature printing.

The machine comes with a HEPA activated carbon filter to keep particles and VOCs out of your room. An active chamber heater can boost the interior temperature to 65 °C.

This means the H2C can run anything and everything with the door closed. I love seeing this in new printers, because I run a lot of PLA and hate having all my doors hanging open. Being able to keep the door closed is also great for families with small children or curious pets.

The H2C comes with a standard PEI flex sheet.

An optional “vision encoder” plate is for 3D printing with exceptional precision. It is covered in a tiny grid that the tool head reads for special optical measurement tracking. Bambu says this plate can ensure an XY-axis calibration solution with a 50µm motion accuracy.

Assembling the Bambu Lab H2C

The Bambu Lab H2C comes fully assembled and only needs to be unpacked.

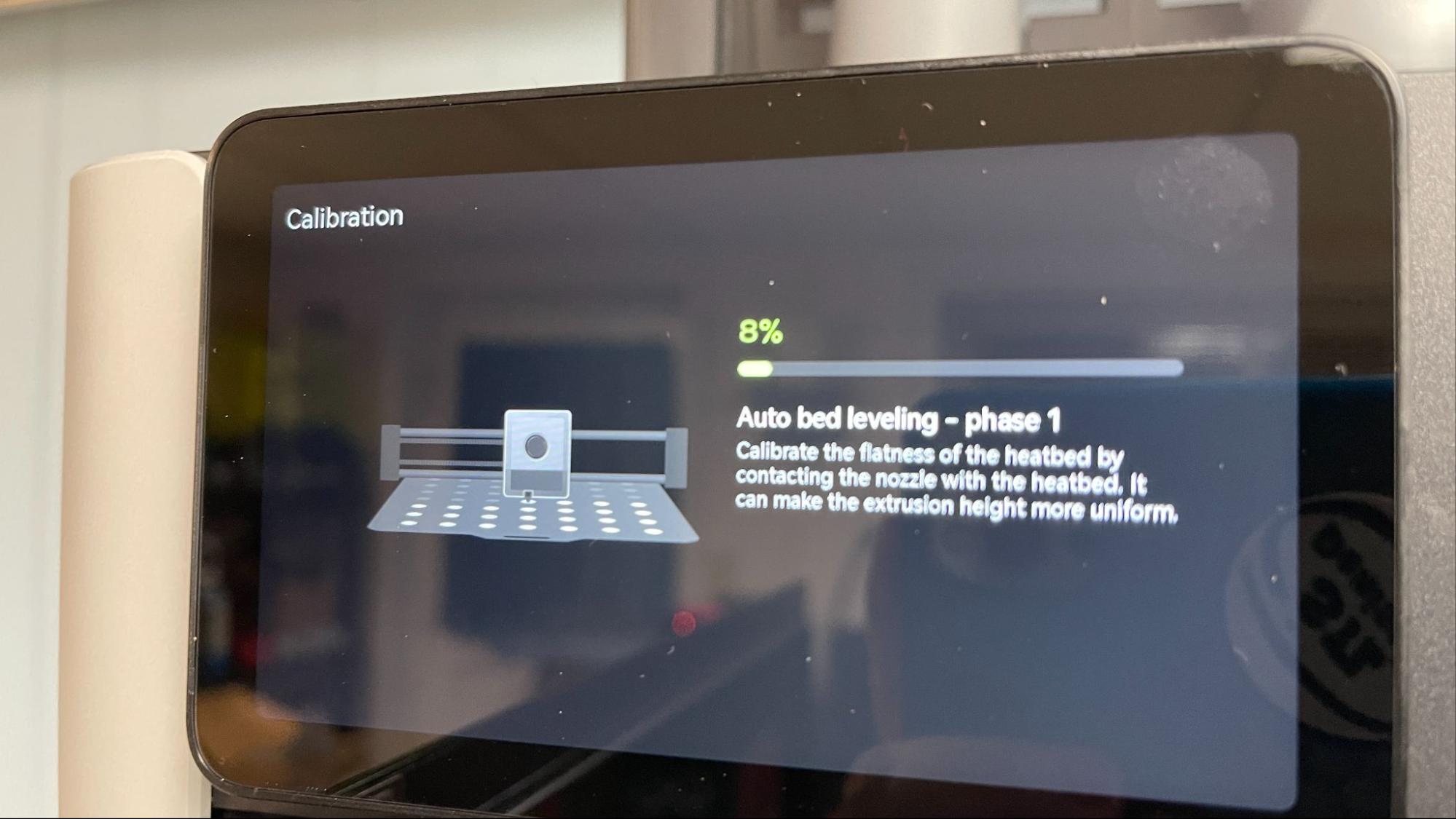

Leveling the Bambu Lab H2C

The Bambu Lab H2C has an excellent auto-leveling system combined with vibration compensation and pressure advance. Due to the dual nozzle system, the initial self-check and leveling will take a good 45 minutes. Thankfully, the machine handles this itself, and you can go get a sandwich and come back when it’s done.

The H2C will check the bed level before prints like the X1-Carbon, and I haven’t had any issues with the Z height during my tests.

Loading Filament on the Bambu Lab H2C

Every H2C comes with an AMS 2 Pro because there is no “single color” option for this machine. Loading filament is a snap with the AMS as you only need to push the filament into the feeding port about an inch and the machine takes care of the rest. If you are using Bambu Lab materials, a sensor will read the spools’ RFID tag and automatically tell the system what color and type of material you are using. Otherwise, manually programming in the filament type and color only takes a few button pushes on the printer’s touch screen.

However, Bambu Lab only sent the AMS 2 Pro for this review, which meant having to load the left side manually. The manual spool holder is on the side, which is better than the rear mounted spool of the first machines. However, there’s only a few inches between the spool and the intake tube, which makes loading three feet of filament tedious. Pressing “load” from the print screen is a long, drawn out process, with the machine making you peer into the tiny gap between the nozzle and the poop chute to confirm that filament is loaded before it continues to purge.

I found it much quicker to load filament through the tool head controls, with the nozzle in the center of the build area where I can see it. If you don’t opt for an AMS for the left side, I would recommend loading the printer with a color you use a lot and leaving it there.

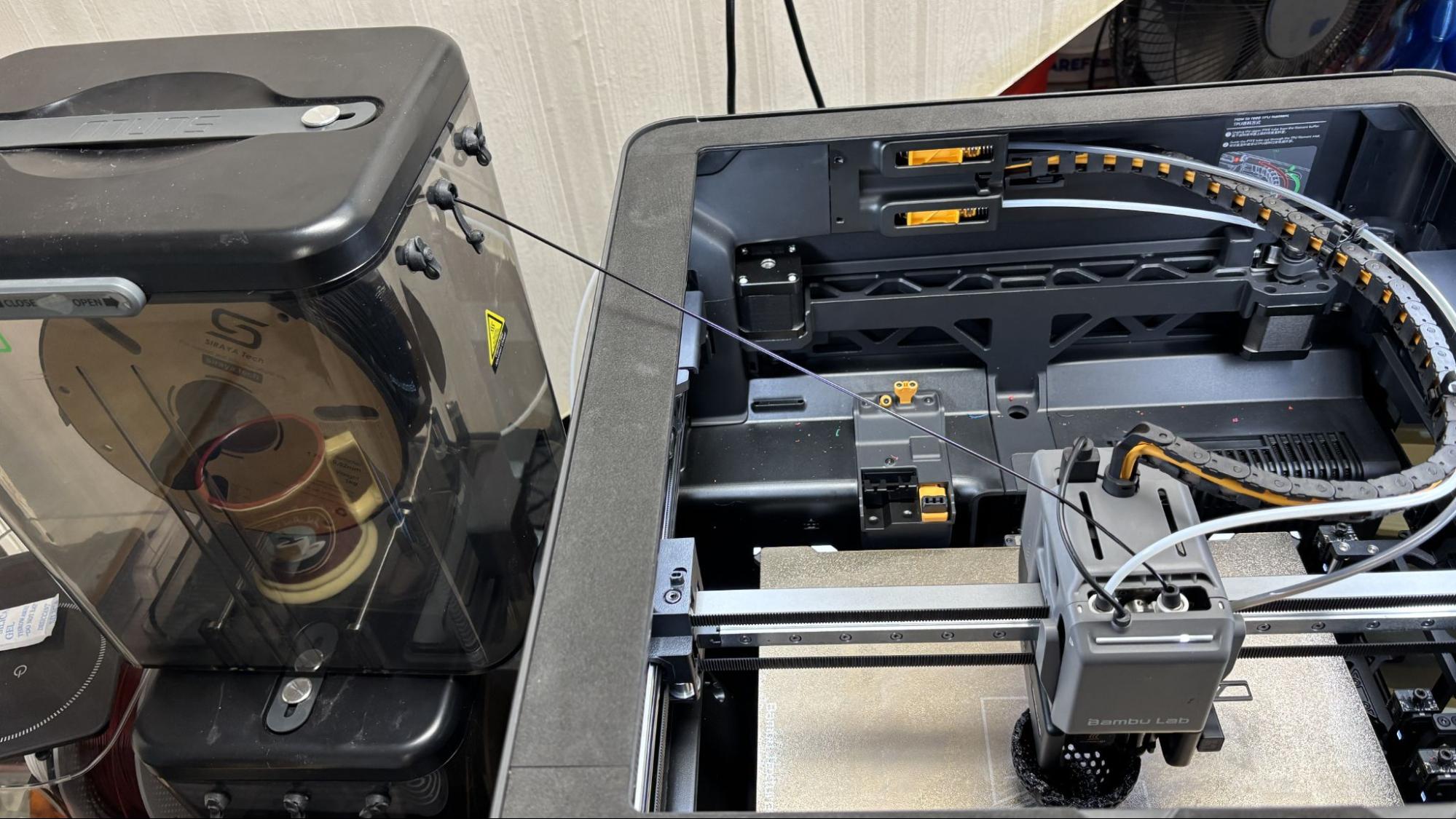

Bambu Lab recommend only using the right side nozzle for TPU. The slicer will not let you run it on the left. They also suggest running it through the top without tubing and letting it have a dedicated Vortek nozzle. This requires removing the AMS from the top, taking off the glass lid and placing an elevated spool holder next to the machine.

The Wiki shows a top mounted spool holder you can print to straddle the opening. I happened to have a couple dry boxes on hand and make a tower of boxes instead. This is enough trouble that I will probably not use this machine to run ordinary TPU ever again, as I have other printers that are less needy. Bambu Lab does make a stiff TPU for AMS that can be printed in the normal fashion.

Preparing Files / Software for Bambu Lab H2C

Bambu Studio was overhauled for the H2D, which also benefits the H2C. The slicer now shows you visual representations of the printer, and it’s build plate, making it easier to see you’re on the right settings. Syncing the printer and AMS now work much smoother, however remapping the Vortek’s filament is janky and never worked for me.

The H2C triggers the “filament saving mode” that is only really needed for the H2D. You’re not going to save a noticeable amount of filament by using the dual nozzle instead of a Vortek one, but you will save some time.

Printing on the Bambu Lab H2C

Our H2C didn’t have any sample filament packed with it, though we did receive a generous box of filament for testing that arrived later. If you decide to order an H2C, I would make sure you select a bundle that comes with filament. Check out our guide to the best filaments for 3D printing for more suggestions to keep your AMS 2 Pro happy.

I started off with a “speed” Benchy” model, with the standard 2 walls, 3 top/bottom layers, 10% infill, and used a .25 layer height and .5 layer width. I then let her rip with Ludicrous mode and got a 16-minute and 37-second print. The print is nearly perfect, with just a rough patch on the bow where it ran too fast for cooling. The camera picks up a few lines, but there’s no ringing, and the smoke stack looks good. This was printed in Polymaker’s Black Hyper PLA.

The Vortek system does a great job of saving filament, putting it on par with Prusa Research’s MMU3, but with easier spool management. It uses a prime tower to keep the plastic flowing smoothly, but it only purges filament poops at the beginning of the print when it sets up the nozzle.

The H2C has no problem with PLA, as expected, and I really like that it has enough cooling and ventilation to run with the door shut.

This single color yarn bowl printed flawlessly in CookieCad Pumpkin Spice PLA, which has to be my favorite filament to stand in for real wood. It’s scented with “pumpkin spice,” so it actually smells like cookies baking when you print it. Unfortunately, the smell doesn’t last after the plastic has cooled. Only the main swirl pattern was supported. The decorative holes ran fine on their own. Notable are the layer lines on the main swirl, which are only visible to the camera. This printed in four hours and 37 minutes, using default settings and a .2 mm layer height.

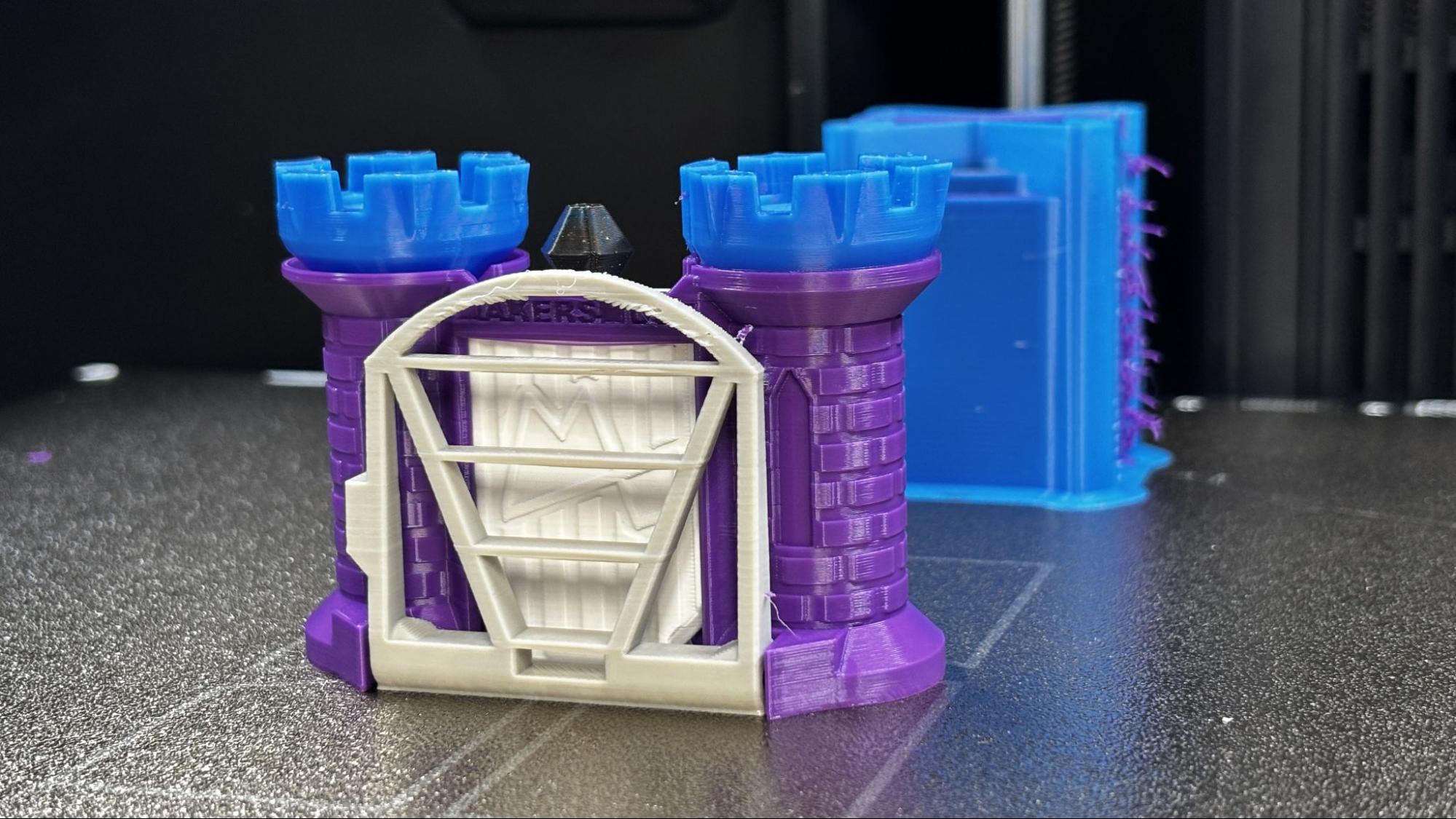

I wanted to run a five-color calibration test on various printers to see how they compare, so naturally I turned to the Maker’s Muse Calibration Castle. This printed in 11 hours 13 minutes, with only a 41g purge tower.

And though the problem of purge has been solved, it is still dealing with an AMS, so it will need time to spool up four (or more) of its colors. I ran the same castle print on the dual nozzle H2D and the 5 tool head Prusa XL.

The results are interesting:

- Bambu H2D: 23 hours and 30 minutes, 70g purge tower and 279g of waste.

- Bambu H2C: 11 hours and 13 minutes, 41 g purge tower, no waste.

- Prusa XL: 6 hours, with a 37 g purge tower, no waste.

And if you’re wondering, yes, you need the purge tower. If you look at the photo below, you’ll see all the stray bits of filament flying off the edge. If you try to print without the purge tower, that mess will be on your print. I tried it, and the print didn’t even make it halfway before it completely failed.

For PETG, I printed a box I made myself using MakerWorld’s parametric model maker on MakerLab. I really like being able to just give the program the dimensions I need and getting a clean, functional print. I needed a box to hold my wax seal kit, so I measured all the things it would hold, punched in the numbers into MakerLab, and got the perfect size. I also whipped up a vase mode inner compartment in Tinkercad to keep it organized. The box is printed with Octogram Spiral as the top surface and gyroid infill to give it a more interesting appearance.

This was mostly printed in Greengate American Blue recycled PETG, but then I ran out and finished it with Greengate Deepwater Blue, which has a similar shade with added glitter. It was perfectly smooth and gorgeous. The sparkles on the vase mode insert really pop.

The print took about seven hours altogether to print. Each piece was printed on its own, as this was a rather large (200 x 160 x 70 mm) project.

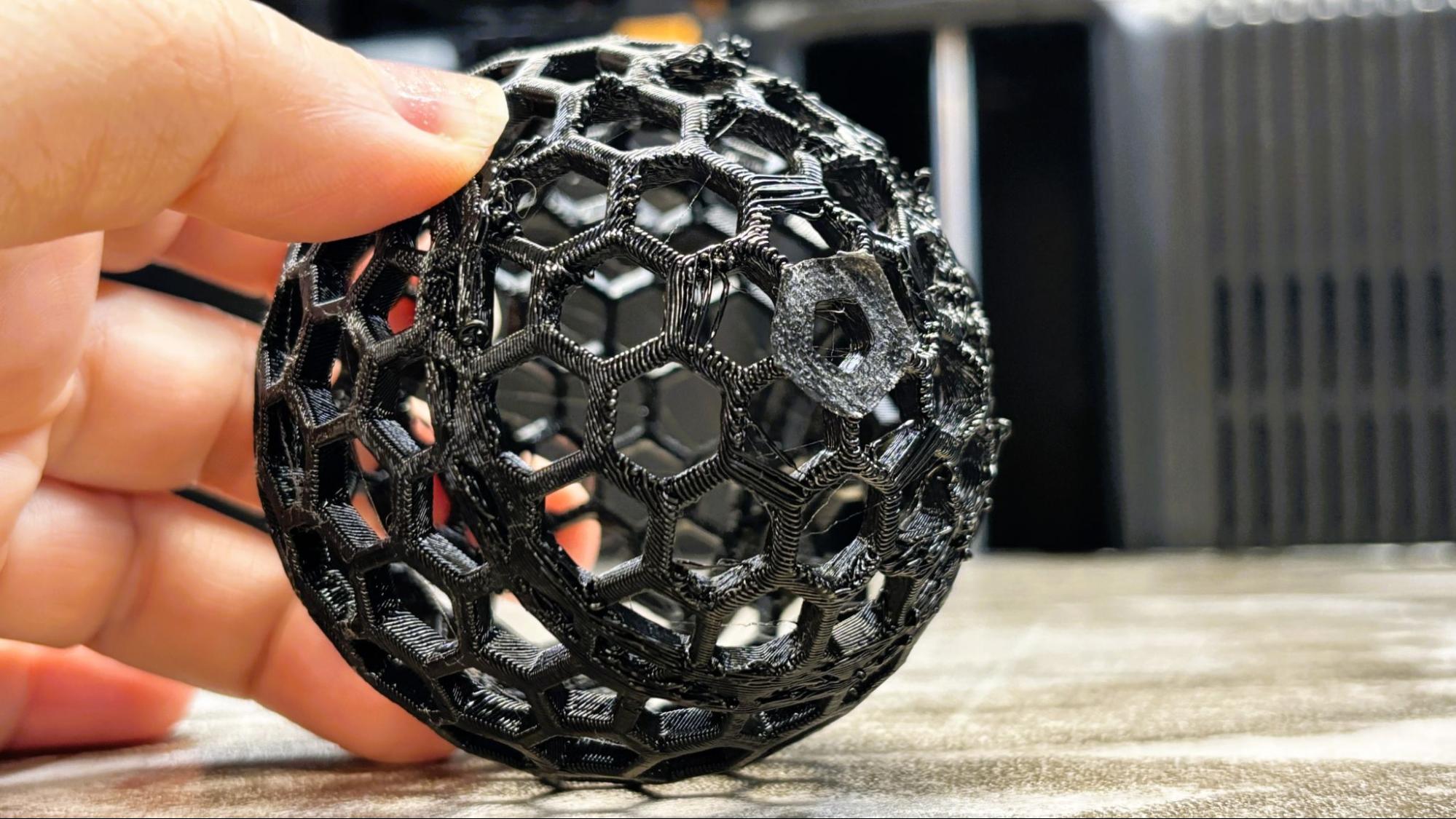

For TPU, I tried something new: Siraya Tech’s 95A PEBA. This is a rubbery TPU with more energy return. I’ve been seeing people print basketballs with it, but I settled for a quicker “air tennis ball” and was not disappointed. It still was a bit wispy, even after drying, and supports are difficult to remove. I attempted one with PETG supports, which immediately failed. This may take a bit more research.

Bambu is now saying that TPU should be run directly from the top, without tubing, into a dedicated Vortex nozzle. This is to avoid cross contamination, but you can still clean the nozzle out with a bit of high temp filament (I used PETG) and go on about your business. However, the slicer will not let you put TPU in the left nozzle without pulling a major fake out on it. This was a bit of a production, so I doubt I will be running TPU in this machine again.

The Airless Tennis Ball V2 was found on Printables by Kimmehead. It took 4 hours and 47 minutes to print with a .4 nozzle and standard TPU settings. I printed it without supports, only a brim. It’s a tiny bit messy, but better than clipping off the supports. It bounces just like a real store bought ball.

I ran a bunch of things in high temp materials, but here’s a fun one I’m working on. This is a dashboard hula girl I’m trying to sort out for my truck driving son. I used all Ambrosia Filament ASA filament, so it will be able to be displayed inside a vehicle without risk of melting. The custom model is by Wekster, who owed me a favor. I then made a skirt inspired by the classic “hairy lion” in Tinkercad. Once I figure out how to 3D print a spring, I’ll share the finished model.

This example isn’t perfect. The supports failed on the flower in her hair, after printing great a half dozen times in PLA while I prototyped it. I think the ASA is a little harder to get to stick to the plate. The failed support put some ripples on her face, so I’ll need to reprint this one later.

Otherwise, it was pretty cool being able to print five colors of ASA. I used a .12mm layer height to bring out the details, so this print took a rather slow 19 hours and 39 minutes to print just her upper half. The legs only took 3 hours and 49 minutes to print, since it was a simpler paint job.

Bottom Line

Bambu Lab’s H2C is a great printer, with its timing spoiled by the competition. Though the Vortek system certainly fixes the filament waste problems, putting it on the most expensive machine is troubling to me. I would very much like to see a “normal” sized printer with a Vortek or, better yet, a full tool changer that takes advantage of Bambu Lab’s full Core XY speed.

With a retail price of $2,399 for the H2C Combo – and, for obvious reasons, no “single color” version – this is not a printer I’d recommend for anyone with a tight budget. But if a large, premium machine is in your future, this is it.

If the Bambu Lab H2C seems out of reach, I’d suggest checking out the Creality K2 Plus, a larger format Core XY with a standard AMS on sale for $1,199. The Snapmaker U1 is the most affordable tool changer on the market right now, and though it is smaller and only has four colors, the $849 price tag looks very nice. If you want a true five-color tool changer, then the Prusa Research XL is the way to go…at least until the INDX is released in 2026.

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing. Denise has been crafting with PCs since she discovered Print Shop had clip art on her Apple IIe. She loves reviewing 3D printers because she can mix all her passions: printing, photography, and writing.

-

S58_is_the_goat I just got an h2s recently, good enough for me since I barely print multi colour stuff.Reply

Just couldn't justify the price for the h2c since it only solves half of the issue, waste but not time like a real tool changer. -

Batweasel Can everyone else open the article? It's just a blank page for me. Everything else I've tried on the site opens OK.Reply -

S58_is_the_goat Reply

Works fine here.Batweasel said:Can everyone else open the article? It's just a blank page for me. Everything else I've tried on the site opens OK. -

CPWilliams1 When I read the comment about WHY there is a dual head instead of a second vortex I wondered if you had actually tested the machine for yourself or if you just tried one kind of material. The Vortex is great until you try to push soft, brittle, abrasive or dusty materials thru the AMS. The added fixed nozzle provides a nozzle that is less finicky with funky materials but/and you can still add multiple AMS units to it (up to 24 filament support) and feed each vortex nozzle and the fixed nozzle. With 7 hot ends swapping and heat up is quick <10 sec and the quality is amazing. My other issue is critiquing the speed of the machine without comparison to other methods of tool head swapping. Other machines my have whole tools swapping BUT they are so much slower in printing that saving a few added moments does not make up for the difference in print speed. the XL prints at 40-60mms and the H2C 80-100 making me think you really have never printed much on either one of them.Reply

We have not mentioned the ability to add a laser and vinyl cutter to it as well.

Bottom line is the Bambu with 7 heads may be the best/fastest/simplest for MANY people people to get started 3d Printing. Bought a H2D for my son, dual print head, printing in just about 1 hour after opening. -

CPWilliams1 Reply

Saves time and waste. and still prints faster than comparables.Admin said:Bambu Lab’s H2C saves plastic, but not time.

Bambu Lab H2C review: It saves plastic…but it's not quite a Tool Changer : Read more