Measurement Science: Taking Accurate IR Thermal Readings

If you thought that buying and unpacking an expensive infrared camera was all that it took to perform professional-level measurements, then it's time for a little lesson. We’ll share some of the knowledge that goes into generating accurate results.

Our Infrared Camera Equipment

Understanding how infrared technology works is one thing. Knowing how to use it correctly to get the right measurements is another. Follow along as we explain the difference between a well-planned infrared measurement and simply pointing an infrared camera at something, since doing the latter usually doesn't get you valid results, no matter what some people say. It doesn't matter if you're talking about graphics cards, processors, motherboards or laptops, the general principle is always the same.

Without a solid handle on the theoretical fundamentals, there's no telling what your measurement might mean. But it's usually not what you intended. That's why we'll spill the beans on our measurement equipment, and then show you what can go wrong. That's good context for comparing the results on other hardware sites, along with their methodologies.

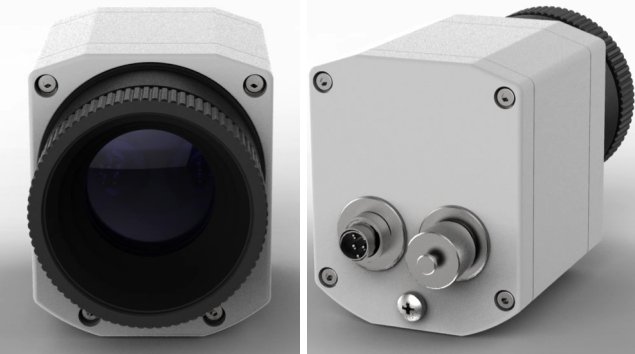

Along the way, you'll learn why we're not using convenient handheld equipment, but instead employ a camera that needs to be installed in a stationary position. It features high-quality interchangeable lenses that can be adjusted based on the subject in question (distance, size of the target to be measured and so on). Doing it this way does require additional time to install and calibrate everything, but you directly benefit from the better results that this process yields, and that's what's most important.

Before we get to the actual measurement methodology and assembly, we'll take a look at the Optris PI640. This particular model is not very well known, which is a shame since it yields reliable measurements when it's used correctly. It's also less expensive than some handheld alternatives, and it provides more options and higher-quality results. All of this is due to it being an industrial solution that is usually permanently installed. The video below shows just how flexible the camera is.

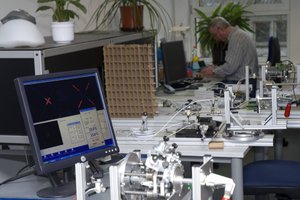

High-end hardware like this doesn't just require a lot of expensive development and production efforts, but also needs regular calibration and maintenance. Without them, even the greatest measurement equipment isn't going to be of much use; daily use changes the exact setup, and aging components do their part to invalidate the results. We try to keep our configuration up to date. That's why we recently changed from the PI450 to the PI640. The latter provides us with even more options.

In case you're interested, we're including a few photos from our development, production and maintenance below. We apologize that we can't show certain things due to their proprietary nature or them being trade secrets, even if they would be interesting to see.

Here's an overview of the technical specifications, before we get to the actual measurements.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

| Optris PI 640 Infrared Camera Technical Specifications | |

|---|---|

| Detector | FPA, Uncooled (17μm x 17μm) |

| Optical Resolution | 640x480 |

| Spectral Range | 7.5 – 13 μm |

| Temperature Ranges | –20 ... 100 °C0 ... 250 °C150 ... 900 °C |

| Frame Rate | 32Hz |

| Optics (FOV) | 33° x 25° FOV / f = 18.4 mm or60° x 45° FOV / f = 10.5 mm or90° x 66° FOV / f = 7.3 mm |

| Thermal Sensitivity (NETD) | 75mK |

| Accuracy | ±2 °C or ±2 %, whichever is greater |

| Interface | PC interface: USB 2.0Process interface (PIF): 0–10V input, digital input (max. 24V), 0–10V output |

| Enclosure (Size / Rating / Weight) | 46mm x 56mm x 90mmIP 67 (NEMA 4)320g, Including Lens |

| Shock / Vibration | IEC 60068-2-27 (25g and 50g)IEC 60068-2-6 (sinus shaped) / IEC 60068-2-64 (broadband noise) |

| Included | USB camera with one lensUSB cable (1m)Table tripodStandard PIF with cable (1m) and terminal blockSoftware package Optris PI ConnectHard transport case |

MORE: Best Graphics CardsMORE: All Graphics Content

Igor Wallossek wrote a wide variety of hardware articles for Tom's Hardware, with a strong focus on technical analysis and in-depth reviews. His contributions have spanned a broad spectrum of PC components, including GPUs, CPUs, workstations, and PC builds. His insightful articles provide readers with detailed knowledge to make informed decisions in the ever-evolving tech landscape

-

samopa Do they have some kind of API, to be connected to other system without using their proprietary software ?Reply -

dmnwlv Respect to tomshardware in its quest here to form a more complete picture in hardware tests and for presenting verifiable (factual) data in its reviews.Reply

I never bothered with all other sites' temperature charts/reviews on gpus ever since toms started doing this. -

FormatC Reply17594187 said:Do they have some kind of API, to be connected to other system without using their proprietary software ?

They have an API and a helpful documentation too. :)

-

Flying-Q I like all the isolation and standardisation you use for consistent, repeatable and accurate measurement. I have a question though: would a cowl over the CPU, chipset and memory make any difference to preventing reflected heat contribution from those components?Reply -

FormatC Only, if the waves goes in the same direction. Upgoing heat is no problem (90° crossing).Reply

I tried it to cover it with a thick, black foam plate - no difference. :) -

dr3cks4u Very good article, thanks for that. I´m sure a lot of people don´t know how time-consuming this kind of measurement is. Question @ Igor: Is the emissivity of the used lacquer constant across the electromagnetic spectrum (=grey body) or is it just known for the camera´s spectral range (7,5-13,0 microns)?Reply