Tom's Hardware Verdict

If you’re looking for a solid, reliable upgrade or a serious entry into resin printing, the Halot X-1 makes a compelling case.

Pros

- +

Consistently solid print quality

- +

Twist-to-Release build plate

- +

Quick-Release resin vat

Cons

- -

Lack of manual slice option in Halot box

- -

Bulky footprint

Why you can trust Tom's Hardware

The Halot X-1 marks a new direction for Piocreat, which is now operating independently after breaking away from Creality. With that separation comes a chance to rethink things, maybe even clean the slate a bit, and in many ways, this printer feels like an attempt to do just that.

It’s a resin printer that leans into simplification, introduces a few fresh mechanical ideas, and delivers solid print quality, if not groundbreaking. After using it for more than a week, mostly on hobby-level projects, I found a lot to like and a few quirks that gave me pause.

This isn't a revolutionary machine, but it does feel like a deliberate shift in approach, with some notable quality-of-life changes that may appeal to anyone tired of the usual resin printing annoyances. The Halot X-1 features a generous build volume of 211.68 x 118.37 x 200 mm, positioning it firmly in the larger format category for desktop resin printers. Coming in at just under $700 (currently on sale for $599), it edges into the higher end of hobbyist pricing, but it may also hit the sweet spot for enthusiasts ready to step up from entry-level machines without fully committing to pro-tier prices.

Specifications: Halot X-1

Build Volume | 211.68 x 118.37 x 200 mm |

LCD Screen | 10.1 inch Monochrome |

Light Source | Honeycomb Matrix Light Source |

X/Y Axis Resolution | 14 x 19 microns |

Normal Exposure Time | not disclosed |

Interface | 3.98-Inch Capacitive Touch Screen |

Connectivity | USB, WiFi |

Machine Footprint | 344 x 331 x 434 mm |

Machine Weight | 12.75 Kg |

Included in the Box: Halot X-1

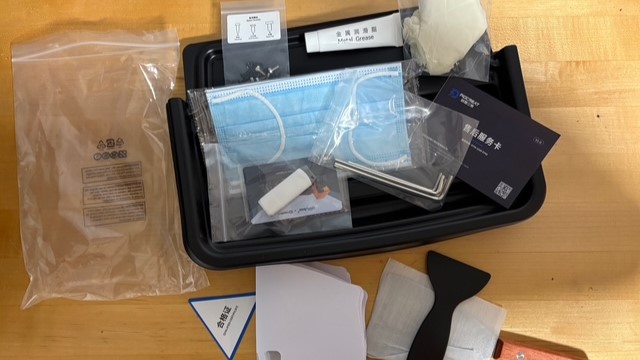

Alongside the expected accessories, such as Allen keys, a metal scraper, gloves, a USB stick, and extra screws, the Halot X-1 includes something I haven’t seen before: a plastic tray, similar to a painter’s tray. At first, I wasn’t sure what to make of it, but it turned out to be surprisingly useful.

You can place the tray under the print bed if you’re removing the vat or use it to catch resin when lifting a model. I also used it as a temporary resting place for the print bed while prepping for post-processing. It’s one of those accessories I didn’t know I needed, not essential, but a thoughtful addition.

Design: A Bit of a Space Hog, But Nicely Built

The Halot X-1 has a fairly clean design; rounded edges, tidy internals, and a subtle look that fits fine in a home or office space. I even like the color scheme, which I realize has practical applications, but still a good look. The bold font on the face gives that “I’m a professional appearance and the white body with UV transparent lid is the proper balance of sci-fi and artistic creation to any workspace. I think my 11 year old put it best, “That’s really cool dad, what are you going to make first?”

The build quality on the Halot X-1 feels solid right out of the box. It sits firmly without any wobble, and nothing rattles or seems loose during printing. The outer casing feels well-made, not thin or plasticky like you sometimes get at this price point. Even the lid is nicely done. It clicks into place when opened, which gives it a satisfying, secure feel like it’s meant to stay put while you’re working.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

That said, this printer does take up a fair amount of space; roughly 16 inches in all directions. If you're working in a smaller setup or sharing desk space, you’ll probably need to shuffle things around to give it a proper home. It’s noticeably larger than something like the Anycubic Mono 3, especially in width and depth, though it’s a full head shorter than the Mono M7 Max while still offering nearly the same footprint. That balance makes it feel like a mid-point between compact and oversized. It’s not the kind of machine you’ll tuck into a corner and forget about; it wants its own space. That said, the design is clean enough that it doesn’t feel bulky or intrusive once it’s in place.

⚠ Printing Safety Reminder ⚠

Uncured resin is dangerous, and the solvents used to clean your prints can be irritating to the skin. As always, we caution you to use gloves and safety glasses when pouring resin and handling uncured prints.

You should also make sure the room you use your resin printer in is well-ventilated to avoid inhaling fumes. Spilled or dripped resin should be immediately cleaned with 99% isopropyl alcohol. After printing, ensure that you wipe down your printer and bottles to remove smudges of uncured resin. Always keep your resin tightly sealed and safely stored out of reach of pets and children.

Assembling the Halot X-1

The Halot X-1 arrives in a large, heavy box—and I do mean large. This isn’t something you’ll casually carry in after work. You might even need to sign for the delivery, so it’s smart to prep your space ahead of time and give the printer a dedicated spot before it arrives. Maybe even warn your partner or housemate that something big is showing up at the door. Once you open it up, you’ll find everything securely packed in thick foam, with the printer and accessories held firmly in place. That kind of care in packaging is always reassuring, especially when dealing with precise components and a high-resolution LCD screen. And if you’ve ordered any extra accessories, don’t be surprised if a second box shows up.

Unboxing the Halot X-1 feels less like unwrapping a gadget and more like setting up a serious piece of equipment. The presentation is clean and well-organized, with each tool and component tucked into place. You’ll find a good range of included items: Allen keys, a plastic tray, gloves, a USB stick, filters, extra screws, and printed manuals; everything you need to get started. Between the weight, size, and thoughtful packaging, it’s clear from the start that this printer isn’t just another hobbyist toy. It’s a more serious machine that asks for a bit of planning and workspace respect right from the jump.

Before diving into the main review, I should mention that my first experience with the Halot X-1 didn’t go quite as planned. I was originally sent what turned out to be a prototype unit, and unfortunately, it was less than fully functional. After several attempts, the best I could manage was a few failed half-prints, nothing usable, and one of those even led to damage on the vat film. Not ideal.

I reached out to Piocreat, and to their credit, they responded quickly, letting me know that a production-ready unit was already on its way. Once that arrived, things turned around fast. The new printer performed much more reliably, and from that point on, I was off and running.

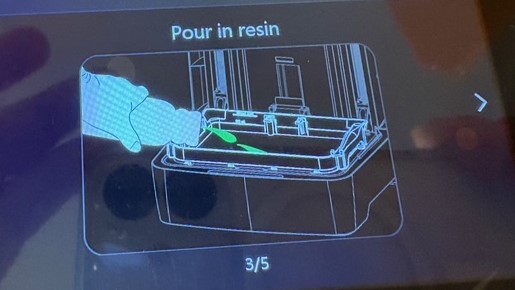

Out of the box, setup went without issues. There were no real calibration headaches, and I appreciated not having to level the build plate. Successful self-leveling is more and more common across printers, but I cannot say this enough… THANK YOU.

The printer utilizes a redesigned internal motion system that eliminates the need for manual leveling, something that has traditionally been a pain point. What really stands out here is the dual Z-axis design, which provides significantly more stable vertical movement. In filament printing, adding a second Z-axis was a total game-changer for print consistency and precision. And now that same upgrade is making its way into resin machines. I remember the difference it made when I installed dual Zs on my first FDM printer. It was night and day. In the resin world, this kind of stability has mostly been reserved for larger or more premium machines (Mono M7 Max, I’m looking at you), so seeing it here gives me a lot of confidence. It’s one of those things you might not notice until it's gone, but once you’ve used it, you don't want to go back.

AFU Auto Resin Feed: Useful for Some, Not for Me

The Halot X-1 includes an Auto Feed Unit (AFU) that lets the printer refill resin on its own. If you’re printing production parts or large jobs with the same resin all the time, this might save you effort.

Personally, though, I didn’t find it very useful. I change resin colors often, especially experimenting with dye in clear resin, and the AFU setup just added another layer to manage. I didn’t dig too deep into the cleanup of the tubing system, but I can already see it becoming a bit of a chore. That aside, the best I can say is that it’s nifty, just not for me.

Water-Washable Resin Support: No Issues

I mostly use water-washable resin because it’s easier to clean, smells less, and isn’t as harsh to handle. The Halot X-1 seemed to have no issues with it. Print quality held up well, and cleanup remains painless.

The 16K Screen: High Resolution, Limited Wow Factor

With a 7680 x 4320 LCD screen, the Halot X-1 offers one of the highest resolutions in its class. It does make a difference. The layers are tight, edges are crisp, and tiny features print clearly. For the first time, I could actually see the flame details sculpted into the side of the dragon trophy model. Something that’s often softened or lost entirely on lower-resolution machines. It was a subtle but impressive improvement that highlighted just how fine the resolution really is. That said, unless you’re doing highly detailed prints on a regular basis, you might not always notice the upgrade. It’s not a dramatic leap in every situation, but when it matters, the capability is clearly there.

Even Light Distribution: A Quiet Win

One feature that isn’t flashy but definitely matters is the 92-zone exposure system, which spreads curing light more evenly across the build plate. I never had an issue with underexposed corners or uneven prints, even when running multiple objects at once. It’s the kind of behind-the-scenes tech that doesn’t get much attention but adds real reliability. And there's proof in the performance; prints cured with this system adhere more consistently to the build plate rather than pulling against the FEP film, which helps reduce wear on the vat over time. Better curing means stronger, more resilient prints, and by minimizing the strain on the film, you’re extending the lifespan of one of the most commonly replaced parts of any resin printer.

Build Plate and Vat Design: Big Improvements in Usability

There are two things here that really stood out.

The build plate and resin vat are two of the most critical components in a resin 3D printer, directly affecting the quality, reliability, and consistency of your prints. A well-machined, flat build plate ensures even adhesion of the first layers, which is crucial for preventing warping or failed prints. If the plate isn’t level or secure, prints may not stick properly or may detach mid-process. Likewise, the resin vat, especially its FEP or ACF film, must maintain clarity, tension, and cleanliness to allow precise curing from the light source below. Any imperfections, clouding, or slack in the film can distort prints or reduce detail accuracy. Investing in quality materials and design here doesn’t just improve results, it reduces frustration and extends the overall lifespan of your printer.

1. Twist-to-release build plate – This made model removal much easier and felt like a small evolution in how print beds can work, as it significantly reduced scraping or fighting to get parts loose. I can’t say “no fighting,” but it is a big leap forward over both Mono 3 and M7 Max.

There is something that has changed, though. We hobbyists are used to laying a print bed on its side and scraping off prints... You could do that here still, although you must make sure that the bed is flush and flat. However, now you just hold it upside down and twist. It reminds me of those old shows and cartoons when the antagonist held some poor individual by their ankles and shook until the goods came out. “Find the fun” is a perspective of mine when approaching hobbies, and this twist is full of it (pun intended).

2. Quick-release vat with lever locks – This was maybe the most unexpected surprise. I didn’t realize how much I disliked unscrewing vats on other machines until I didn’t have to anymore. With the Halot X-1, I can pop the vat out with one hand - no tools, no stress. It's genuinely convenient. As the pour edge is large and more pronounced, there’s no recoil of resin while emptying the vat back to the main body. Just tip it over (hold it properly at an angle) and pour it out.

Unfortunately, these design changes come with small trade-offs. The new build plate design, while clever, does feel a bit “loose” when you first insert it. It takes a little getting used to and can feel less secure than traditional mounts, even if it ultimately locks in just fine. Similarly, the shifting plates make cleaning more difficult, especially during your first few runs. My initial prints left small patches of resin still adhered to the plate, and figuring out how to clean around the moving parts wasn’t as intuitive as I expected. Removing those remnants as the plates shifted on my workstation required some trial and error. That said, with a bit of practice, I found a rhythm that let me clean efficiently and move on without adding too much time to my workflow. There was definitely some anxiety at first, but after a few successful cycles, that gave way to confidence.

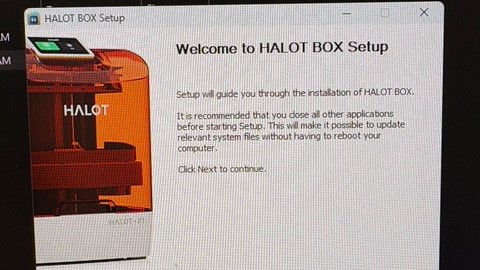

The Halot Box Slicer Auto-Slice is… Different

The Halot X-1 uses Creality’s Halot Box slicer (still branded under the old name, despite Piocreat’s split), and overall, it’s a surprisingly competent piece of software. The interface is clean, the layout feels deliberate, and it’s easy to navigate whether you’re new to resin printing or just new to this particular environment. The core tools: model arrangement, support generation, and exporting are accessible and visually intuitive, without the overwhelming clutter some slicers fall into.

One feature that genuinely caught me off guard, in a good way, is point-to-point measurement. This tool lets you click between two exact points on your model and instantly see the distance. It’s one of those utilities that feels so obviously useful that you wonder why more slicers don’t include it, or at least, why it’s not more prominent elsewhere. Whether you're verifying tolerances, planning clearances, or just double-checking design dimensions, it’s an invaluable addition. If other slicers aren’t doing this, they really should be.

That said, Halot Box does take a different approach when it comes to slicing. There’s no manual slice button. Instead, the software automatically slices your model when you save or export it. At first, this felt like a loss of control. I’m used to reviewing sliced layers, checking resin usage, and seeing estimated print times before sending anything to the machine. Not being able to do that upfront made me uneasy. But over time, I came to appreciate the simplicity: it’s one less thing to worry about in a process that’s already fairly involved. Still, I’d prefer to have the option to slice manually, especially for transparency and troubleshooting.

Despite those quirks, Halot Box feels thoughtfully put together. The icons are well-designed, and even after weeks of use, I get the sense I’ve only scratched the surface of what it can do. As I continue experimenting with more complex prints and deeper settings, I’m genuinely interested in exploring what else is under the hood. While it may not yet match the power and flexibility of third-party slicers like Lychee or ChiTuBox, it holds its own and offers a surprisingly user-friendly experience right out of the box.

Maintenance and Replacement parts for Halot X-1

Like any resin printer, the Halot X-1 will eventually need new parts, whether it’s the vat, the film, or even the print bed. Because this is Piocreat’s first independent release, it’s still unclear what those parts will cost, how easy they’ll be to get, or what unexpected components might be harder to replace. That’s something I’ll be keeping an eye on, and I’d advise other early adopters to do the same.

I did have somewhat regular correspondence with Piocreat throughout my run, and if their attentiveness to me translates to their service to all customers, they’re going to make fast friends out there. Stay available is my advice to the developers. If you’ve been doing this for any time, you know. And if you’re new, you will. Sometimes you have to wait for Reddit and YouTube to locate videos and threads to solve common problems that a simple customer response effort could have handled. That kind of response and handling builds loyalty.

Halot X-1 First Test Prints: Promising Results

To start simple, I printed a basic geometric test piece, something designed to highlight layer alignment, surface consistency, and support behavior. What came off the build plate was crisp, with clean edges and barely a mark left from supports. Even with minimal support settings, the print stayed secure throughout the process, and there was no sign of warping or lifting. Right out of the box, the Halot X-1 felt well-tuned.

For a more demanding test, I loaded up a trophy model I’ve printed often; a layered design featuring a clean base topped with a twisting dragon sculpture. It’s got sharp angles, overlapping wings, textured scales, and tight details that push a printer’s limits. The Halot X-1 handled it impressively well. Finer textures, like the ridges of the wings and even individual teeth, came through more sharply than expected. In fact, for the first time, I noticed faint flame details sculpted onto the side of the base, something I hadn’t noticed in previous prints using the same water-washable resin.

Print speed was also about what I expected. There wasn’t a noticeable gain or loss in time compared to other printers I’ve used, including the Mono 3. The Halot X-1 didn’t feel faster, but it didn’t slow me down either. For the kinds of prints I typically run, it held pace with the rest of the field.

👉 Compared to the Anycubic Mono 3: A Close Match

My go-to printer for a while now has been the Anycubic Mono 3, which has earned its place thanks to consistent results and ease of use. When comparing prints from both machines side by side, the Halot X-1 holds its own and even edges ahead in certain ways—especially with small surface details and how cleanly it releases models from the build plate.

The overall print quality feels on par with the Mono 3, which is saying a lot. What really stands out is the Halot’s usability: resin cleanup is a little easier, model removal is less stressful, and the interface is more polished. I still have a lot of respect for the Mono 3, but the Halot X-1 is giving it real competition, and has me seriously considering a permanent switch.

What the Halot X-1 Gets Right

✅ Consistently Solid Print Quality

From simple geometric shapes to highly detailed models, the Halot X-1 delivers clean, accurate prints with reliable support performance. Even on first use, it produced strong results with little need for tweaking.

✅ Twist-to-Release Build Plate

This design change makes model removal much easier. Instead of scraping and prying, you can release the build plate with a simple twist, which not only protects your print but also saves time and effort.

✅ Quick-Release Resin Vat

The vat system ditches the traditional screw-based mounts in favor of lever locks, allowing you to pop it out with one hand, no tools needed. It's a small change that dramatically improves day-to-day usability, especially when you're cleaning or switching resins.

Areas That Could Use Improvement

❌ Lack of Manual Slice Option in Halot Box

The auto-slice feature in the Halot Box slicer is convenient, but it comes at the cost of control. Without a manual slice button, you're unable to preview resin usage or estimated print time before exporting; a feature many users might consider essential.

❌ Bulky Footprint

The Halot X-1 isn’t small. At approximately 16 inches in every direction, it occupies a significant amount of space. While this allows for a decent build volume, it may be challenging to fit into smaller workspaces. A slightly more compact design could broaden its appeal without sacrificing performance.

Bottom Line

Taking everything into account, from the hardware to the software to the overall user experience, the Halot X-1 earns a solid 4 out of 5 in my book.

This printer doesn’t just check the boxes; it brings a few smart innovations to the table, such as the twist-to-release build plate and quick-release vat system, that make it genuinely more enjoyable to use on a day-to-day basis. The print quality is consistent, the machine is quiet and stable, and the high-resolution screen delivers on its promise, especially when it comes to capturing fine surface detail.

Yes, there’s still room to grow. The software could benefit from increased control and transparency, particularly in areas such as slicing previews and print time estimates. And while the machine’s footprint and initial learning curve may give some users pause, these are tradeoffs that feel reasonable given what’s offered here.

It’s also worth noting that the price, at just under $700 (on sale for $599), puts the Halot X-1 at the higher end of the hobbyist market. For casual tinkerers or those just dabbling in resin printing, that might be a stretch. But if you’re ready to level up or looking to invest in a more capable, thoughtfully designed machine, it’s a cost that feels justified by the experience.

In a landscape crowded with hobbyist 3D printers, the Halot X-1 doesn’t just blend in, it steps out boldly, with features and polish that show it’s ready to compete with more established names. It feels like a printer built by people who understand the frustrations of resin printing and actually tried to solve them.

The Halot X-1 isn’t perfect, but it does a lot of little things right. It introduces subtle, smart improvements over a typical resin printer, aimed at making resin printing more accessible and less frustrating, especially for hobbyists who are tired of the usual routines and looking for greater ease of access to build plates, vats, and prints.

For a first independent release under the Piocreat name, it’s a solid effort. Whether or not it’s the right printer for you depends on your priorities.

MORE: Best 3D Printers

MORE: Best Budget 3D Printers

MORE: Best Resin 3D Printers

-

egmccann I picked up the Halot X-1 on the kickstarter, so I got it and the resin pump for under the $599 price. It's had some early quirks (which I expect, and which have been improved.)Reply

I somewhat disagree with the description of it being "bulky." If you're coming from one of the smaller resin printers (in my collection, for instance, I have an Anycubic Mono 4 Ultra,) then yes, it will seem that way - but it has a bigger print area. By comparison, it currently works alongside my Saturn 4 Ultra, having roughly the same footprint yet being shorter, so it actually feels compact to me.

The build plate and vat mechanism are the entire reason I bought this - honestly "out of curiosty," but they have been solid with all the printing I do. And yes, I 100% love the handle/latches for the vat over having to screw/unscrew vats in. I really want more printers to take that, if nothing else, from this device. It holds the vat very securely (it has to, given the whole mechanism travels.) If I could retrofit my Saturn 4 with latches like that (and the hoopat system for film replacement,) I would in a heartbeat.

The software's the biggest letdown in the whole package, both on the printer and on the PC, at least if you want to send it OTA using Halot Box. First you have to make sure the printer's not sitting there saying "print complete" or anything, or it'll ignore any file sent to it, despite looking like it sent. Then you go prepare the print (and this seems to hate giving explanations of anything - I print larger figures, generally hollow them out, which means I have to put in drain holes... and it'll just seem to randomly say "no" to that with no explanation.) Once you slice it, save it, then ... you don't send the file, you have to go back to the very *first* step (where you'd be putting the model on the plate) to get to the icon that lets you *send* the model via wifi to the printer... assuming it finds it, and you have the password in (which you do *not* have an option not to use.) Then it'll say it sent... maybe... if it found the printer. If you're lucky, you'll get to tell it to print, otherwise you'll have to walk over to the printer (in which case, why'd you have the wifi option?) and tell it to print... then tell it to start the print. The back and forth is not a good workflow, it doesn't really give a good status, and half the time you're walking to the printer anyway (so you might as well just save to USB.)

I *really* hope they fix this workflow - or that we get to slice and send via Chiitu or Lychee, which we currently can't do the whole workflow in.

The pump... The pump works, it'll read resin info from the ... two? bottles of standard 16k resin set up for it. (Might be more in the water washable or some such, I just use the 16k standard, and there are only two options.) Not even other Creality or Halot resin has the RFID tag in the bottom it needs, and of course it doesn't talk to the Halot Box software to say "hey, this is what I have, use this profile." (Maybe if you connect by USB?)) It leaves a fair bit of resin in the bottle when it reports "empty," though, at least in my experience. I'm torn on if I'll keep using it or not. It's convenient...ish, but... eh.

I'd say the printer itself is absolutely worth a look, I've gotten great results, but the software needs more time to cook. Maybe by the time Black Friday sales roll around...