ASML and SK hynix assemble industry-first 'commercial' High-NA EUV system at fab in South Korea

Initially for R&D use, until later this decade where it will transition to production

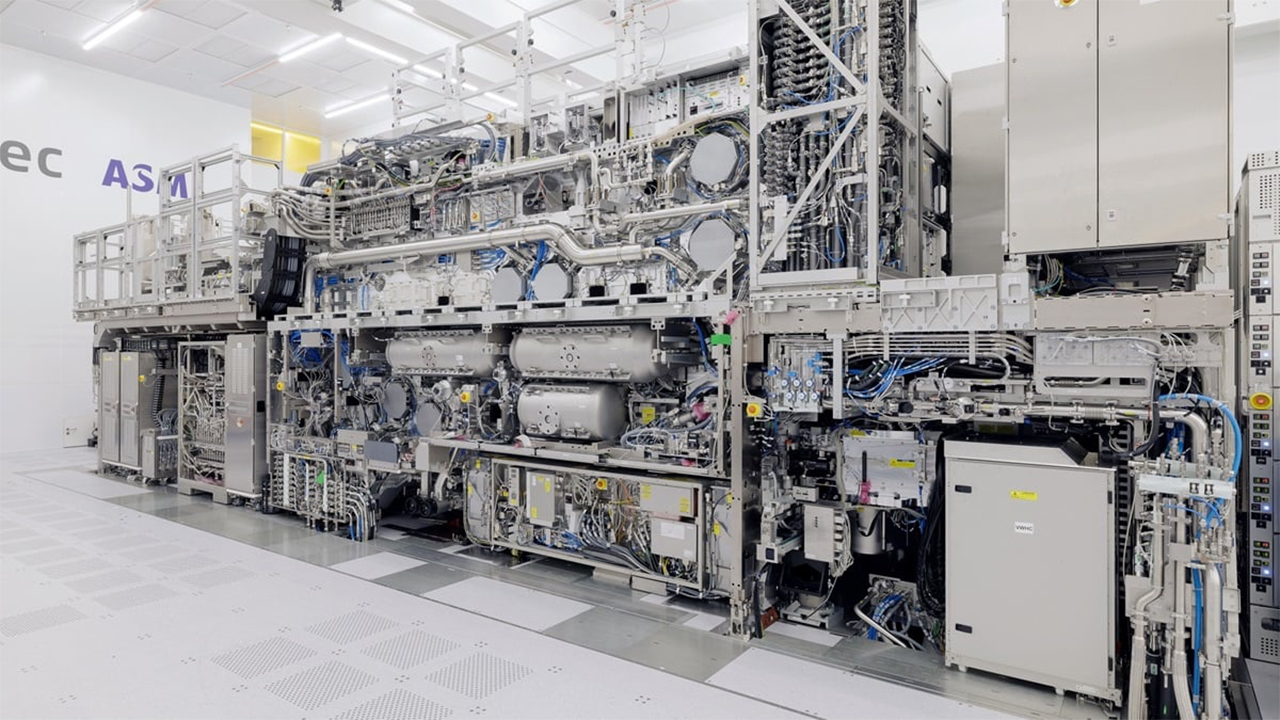

SK hynix and ASML early on Wednesday announced that they had assembled the industry's first Twinscan NXE:5200B High-NA EUV lithography system at the company's fab M16 in Icheon, South Korea. The device will initially serve as a development vehicle for next-generation process technologies, but eventually it will be used for mass production of DRAM using leading-edge process technologies a few years down the line.

For SK hynix, the assembly of one of the industry's first Twinscan NXE:5200B EUV system with 0.55 numerical aperture optics means that it leaps ahead of its arch-rivals Micron and Samsung as well as the vast majority of companies across the broad semiconductor industry, many of which still must adopt existing EUV systems with a 0.33 numerical aperture.

"We expect the addition of the critical infrastructure to bring our technological vision we have been pursuing into reality," Cha Seon Yong, head of R&D at SK hynix. "We aim to enhance our leadership in the AI memory space with the cutting-edge technology required by the fast-growing AI and next-generation computing markets."

ASML's Twinscan EXE:5200N with a 0.55 NA lens achieves 8nm resolution — compared to 13nm on current Low-NA EUV tools — enabling 1.7 times smaller transistors and 2.9 times higher transistor density in a single exposure. While Low-NA tools can match this with costly multi-patterning, High-NA EUV simplifies lithography steps, albeit at the cost of new technical challenges.

Given the capabilities of High-NA EUV machines that allow chipmakers to avoid double or triple EUV patterning, the NXE:5200B will initially be used to fast-track prototyping of next-gen DRAMs to be made using process technologies that rely on existing Low-NA EUV and DUV tools. Only then the tool will be used for development of fabrication processes that will actually mandate usage of High-NA EUV equipment for proper yields and cycle time. ASML estimated in one of the presentations for its investors that DRAM makers will transit to High-NA EUV tools in the 2030s.

Rapid prototyping greatly speeds up development of next-generation process technologies. The High-NA EUV machine enables detailed prototyping of DRAM structures (e.g., capacitor trenches, bitlines, wordlines) at a higher pace than is possible on existing Low-NA EUV tools, which gives a critical boost to SK hynix's R&D.

In the long-term future (towards 2030s), SK hynix can use this tool to test patterning limits, develop new layouts, and evaluate new materials it will need for fabrication nodes that obligate usage of High-NA EUV tools, well in advance of needing to commit to full High-NA EUV-based production.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The assembly of ASML's first Twinscan NXE:5200B machine at a client site (in this case SK hynix's M16, which is indeed a mass production facility) marks a milestone for the company as previously it built Twinscan NXE:5000 machines at Intel's D1X development fab near Hillsboro, Oregon, where they have produced tens of thousands of wafers already. The NXE:5000 systems are considered pre-production, but they can be upgraded to gain performance required for high-volume manufacturing.

"High-NA EUV is a critical technology that opens the next chapter of the semiconductor industry," said Kim Byeong-Chan, ASML’s head of customer team. "ASML will closely collaborate with SK hynix to bring forward the innovation of the next-generation memory."

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button!

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

thestryker Seems like this does confirm ASML changed something with the 5200 series before shipping as it has a "B" suffix. It will be interesting to see how many High-NA machines ASML ends up shipping this year when the final numbers are released.Reply -

Honk Honk What kind of AI wrote this nonsense? NXE:5200B and NXE:5200N does not exist and neither does NXE:5000.Reply -

checksinthemail Reply

https://www.asml.com/en/products/euv-lithography-systems/twinscan-exe-5200bHonk Honk said:What kind of AI wrote this nonsense? NXE:5200B and NXE:5200N does not exist and neither does NXE:5000. -

Honk Honk Reply

You read your link right? EXE:5200B and EXE:5000 exists, all other mentions seem like hallucinations by an AI. High-NA systems are not sharing naming scheme with normal NA EUV systems.checksinthemail said:https://www.asml.com/en/products/euv-lithography-systems/twinscan-exe-5200b